Engine overhaul — logbook Toyota Supra 1990

After the second time the gasket was blown out, I decided to put a steel one. At the same time, I had an uneven surface of the block, and in this case it is necessary to trim the block, for which it must be removed from the car - this is of course if done "wisely".

In short, we take out the block - so let's measure it and throw at least the liners - if everything else is buzzing. But measurements showed that the ellipse is 6 acres and it can be brought to the maximum gaps for this motor of 13 acres, but then the oil appetite will certainly not be weak ... In short, new original repair pistons, boring a block for them and trimming. No sooner said than done (in Voronezh they did).

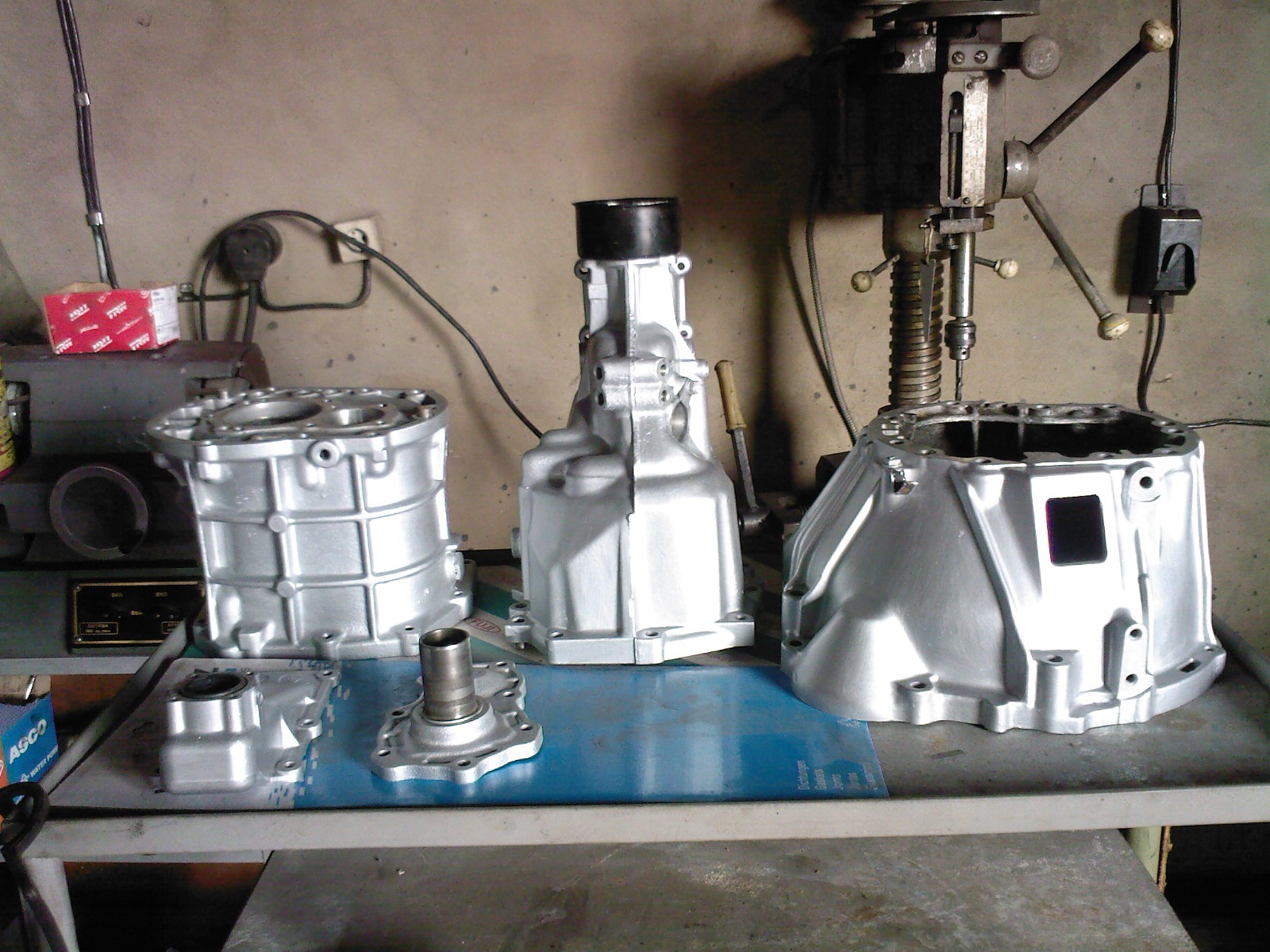

Well, liners, gaskets and all small things. At the same time in the process and swapped fur. It was the atmospheric W58 that came with the car and it was rebuilt.

The clutch had to be ordered in America - 400 forces of the atmosphere will not work, and the stock turbo with my turbo, according to the experience of older comrades, will give up 1 kg, and it was supposed to be 1.3 bar excess. By the way, I really liked the Spec stage 3 clutch - soft, the moment of engagement is felt quite well - in general, it is slightly different from the drain, and, according to the assurances of the Merikos, it holds more than 500 Newtons.

In general, they assembled it for me only in December, and on December 20, on winter non-studded high-speed tires, they began to run it. Alas, already on the third day, with a run of just over 100 km (for a combat engine, in principle, running-in is no longer needed - I adhere to American methods) at a boost of about 0.8 bar and the engine blew up and went out ... In short - either the settings of my blende of brains, or early ignition — But detonation is our best friend … Piston and candle on the first cylinder.

Well, the rest also swam - and badass on all cylinders - and Toyota does not have a second repair size! But there is a way out - forging on 7M in two more sizes (0.5 and 1 mm) is done in America - I took a 0.5 piston and needle rods, a block was turned under them already in Moscow - and the motor fell into good hands ... in resulting in the spring she went again!

True, on the native flow meter - Maft-Pro was sold and bought by AEM. At the beginning of the summer, she again advanced to install new brains and all sorts of other goodies. But more on that later.