Porting 2jz-gte — logbook Toyota Supra 1995

Hi all!

In hindsight, I post a report on what I did and did it make sense ?!

Until measured impellers are tired of me.

it feels like it rides well, but it’s impossible to say that this is the result of porting, since the engine was capitalized too.

All work was carried out with a dremel with an emery wheel attachment and under the type of grinder

First, I removed any bulges that could be seen left after casting.

The procedures went in several stages. I thought I’d just polish and remove the burr, but it sucked in bulk :)

Question for the experts how to proceed ?!

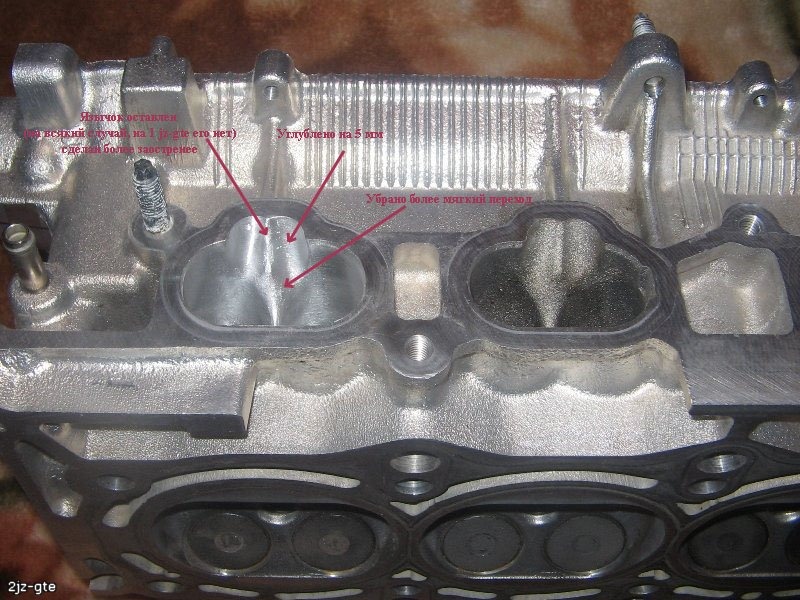

in the inlet window, where the forces are located, there is such a tubercle that divides the injected fuel into two parts, I don’t see any sense in it, so then there is still a large partition that divides the entire flow into two parts (by the way, I grinded this partition from 5 mm to 2 mm)

this is how at the moment everything looks like I can’t stop and I’m climbing and polishing and polishing the windows (

I’ll wipe it soon :)

after measurements, the inlet windows increased by 12% (how did you measure it? I put the valve. Then I laid my head flat and poured water with a syringe until a "hill" appeared, while the water was still held due to surface tension, I received a certain amount of ml (for memory something 127 ml but I don’t remember it for a long time) and had the old one stopped before porting, cut it divided by the new one and multiplied by 100) but I want to say that in fact, after these measurements, I squandered the windows even more, it was already over 25%

, here is a photo that shows 12% and you will understand how far it is from what happened

graduations are only rubbed to a shine - boring is not provided

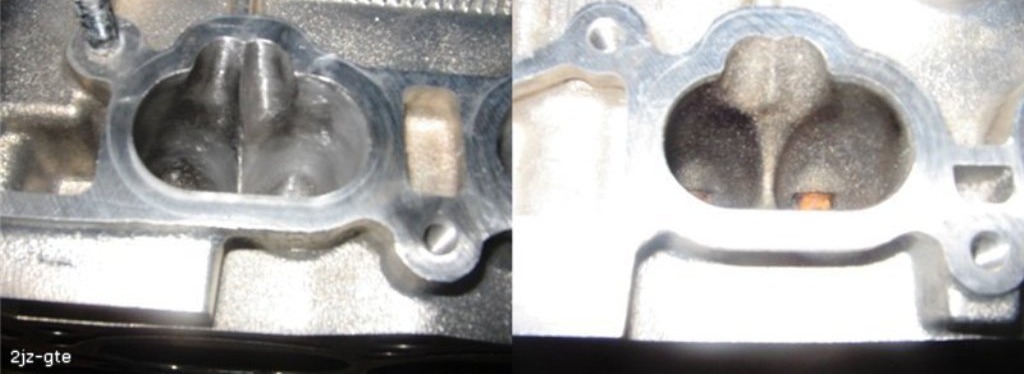

and this is what the release windows looked like)

these are the nozzles with which the main work was carried out

and this is how much borohl was cut off in 10 minutes

, I don’t know how much it is in grams, but for the entire time of polishing the bag of the vacuum cleaner scored to failure)

this is the head sawing machine itself (two flexible cords were killed)

this is what happened, fotal but a hundred so the quality is appropriate

if honestly there is no desire or time to upload good photos. Satisfied with the work done. only a very hemorrhoid

mirrored with GOI paste (large and small) was saved by a leather nozzle for polishing, felt circles didn’t work for something.

and with these nozzles he preliminarily rubbed (although they began to "smear" aluminum) then he went with goi paste!

intake mirrored only half, completely mirrored issue!

in general, I have been doing porting for a long time, so to speak, a winter hobby!)

I will wait for comments...

Many dissuaded me from this idea, they said that I would violate the calculations (some kind) and the type of air would not flow evenly.

my opinion:

1) stock collector and so the curve!

2) Whoever looked at the head saw that all our windows are different, even two paired windows and they differ from each other

3) it seems to me that if there is a certain pressure, then it will be the same in all windows, but how much air gets into the chamber depends on the opening time and valve diameter, and I did not touch the valve seat.

well, this is my IMHO

, although if you follow it, then boring should not give anything either

not all the photos are there!) I sharpened mainly from the intake side to the valve, the main work was going on there, just checking how much it expanded, etc.

then removing the valve and from the side of the valve seat removed everything and polished it in the same place. not polished to a shine only where the forces in my opinion are sprayed. it’s just that on a smooth surface, gasoline seems to be going into drops, and so what kind of roughness

And that Issue completely mirrored (by the way, I remember how I polished it. There was a coating of up to a couple of mm in places, there were so many slags that horror)

since we took it apart with 2JZ twice the motor, then after the first plant, looked into the intake, there immediately such a plaque began to form, but it was easily removed by hand. so I think it will have to be blown off in a subsequent running-in)

The inlet glowed a couple of cm from the side of the saddle, the rest of the inlet was bored, since the seat was pressed in places, I saw a not bad step from the saddle, I also removed it)

just so that there were no sharp corners and protrusions.

there should not have been an increase in pressure, but you should have increased the throughput and flow rate

Hey! Porting was completed a long time ago!

And the car went through a lot of baptisms of fire)

I don’t even know what porting gave?

I don't have a boost sensor, so I can't say that there was an increase in pressure. and in addition to porting, a forward flow was made, and of course, the capital of engines and turbines.

Yes, I also thought so about the tubercle, but no matter how many ported heads I looked at, this tubercle is also removed at 0 there. okay, they also grind down the valve guide)))) and this is not done by the "woe" of the master, but by those who still chase themselves and have a name in the tuning environment) The only thing that made me happy in communicating with them is that many also check with water "sameness" of the inlet windows.

Good report. It will be interesting to see the result. In theory, it should be, at least small, but it should be ...

That's just that partition (like a ridge), I think you grinded it in vain ... I dare to assume that it divided the stream into two parts, and directed each of them to its own window. Even before the big barrier. (As it were, she helped. She set the direction)

In general, intervening in flows is not the best thing, I think. Still, Toyota did not just design all this. They then designed and calculated all the twists, barriers, obstacles, etc.

Porting, as it were, is the right thing. When casting a block put on stream (not handmade), it is logical that irregularities and roughness remain. Removing them is the right thing to do ...

In short, the work is titanic. Respect. I wonder how it will affect the work.

And I'm still watching... :)

Yes, it was also necessary to put 1mm more valves)

I still have not solved the problem with some nickels under the valve glasses, stupidly not all valves open to the desired level. everything doesn’t get to them)

And for some reason the sound on my car on v8 looks like it’s grumbling, it’s not a row six, but something like a v-shaped one. Like a fool, that one is just louder, but the tonality and mannerisms are named after him))))

a friend on JZ put a valve of a larger diameter. besides doing porting inlet/outlet. According to reviews, the nature of the engine has changed quite significantly, especially at low revs and for the better.

If you believe the manual, then only the gap between the glass and the camshaft is measured.

but no, there’s definitely something there that measures the length of the valve, suddenly sat down or stretched out)

well, you probably don’t measure it, only you can set the gap

Unfortunately, the readings of the "popometer" do not count) even a 402-meter race may depend on many factors, and not on the porting itself. here you need to go to the dyno stand.

It's hard to say exactly how much growth there was. now I think that my valve clearances are not correctly set, the opening is down.

while it's cold, as it gets warmer, I'll measure all the valves