The rules of orthoepy: the truth about the origins!

So, developing the theme of return to roots is a wonderful host and the most wonderful modern Soviet car of the 60s, will continue the theme of orthoepy early transmission of family 408, agregatirovatsya with the best Soviet motor — Москвич412. As I mentioned, differences from the average, and the more — recent publications — MASS. At first glance, they are insignificant, and practice aggregate repairs — the so-called obeliski, when the enterprise had a certain number of reserve engines/bridges/boxes and they were indiscriminately placed on all row cars under repair. and thereby violated the factory kits were rassasyvanie and lost units., fatal had his say. But not in this case and it is great.

Extention cord CAT early release — perfect view of the breather ventilation, and families 402-407

Extention cord CAT early release — perfect view of the breather ventilation, and families 402-407

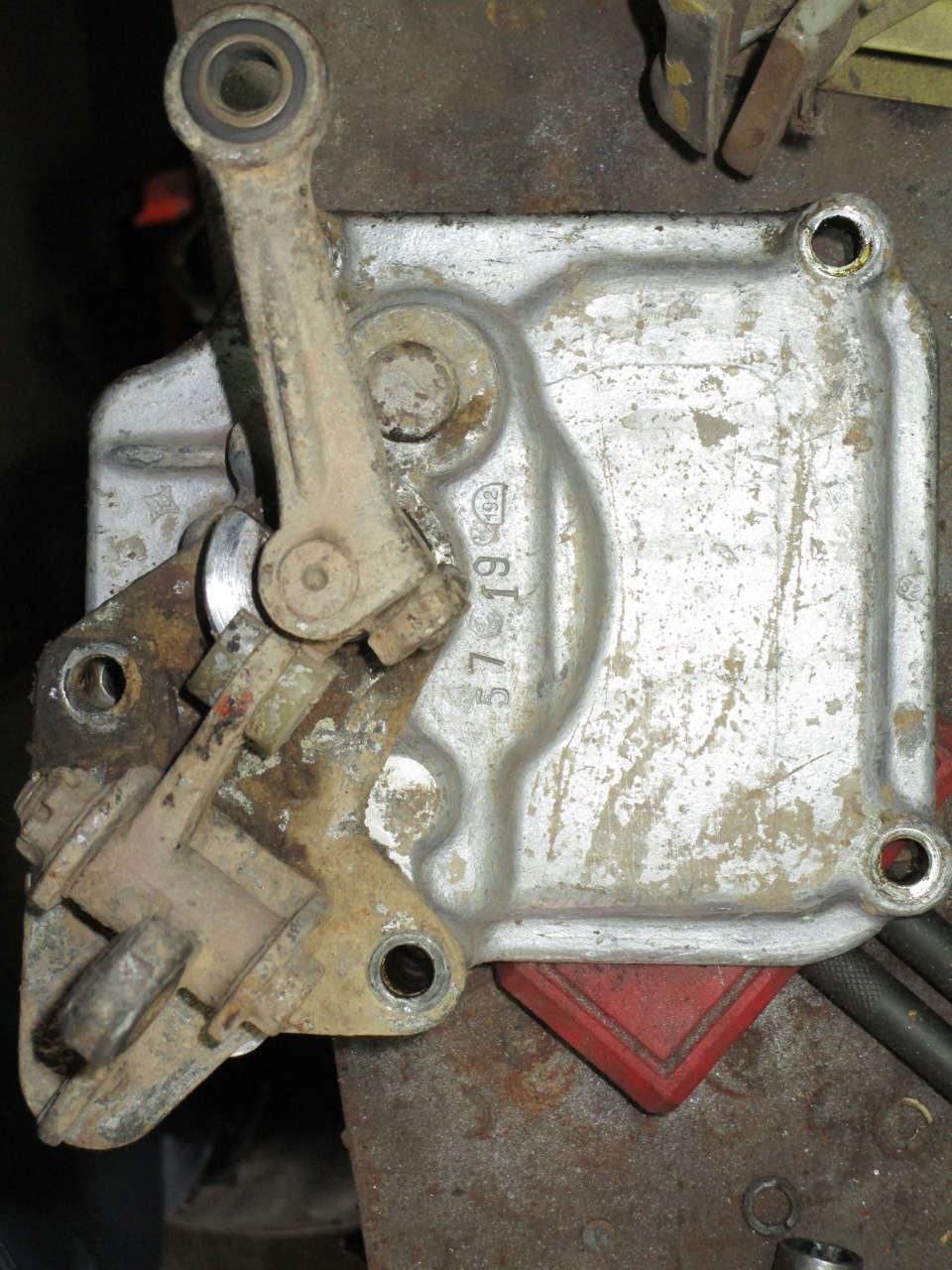

Management cover — left hand Luke CAT also is very different the quality of performance, the casting form and shape of the individual parts. For example — managing and selecting levers made much neater all subsequent.

Managing cover with traces of oxides of galvanized parts

Managing cover with traces of oxides of galvanized parts

Clear case cover has undergone full disassembly and re-cleaning, at the same time on different parts of the detected 13 brands(!) so treat quality control in the company-the Main supplier of conveyors MZMA(then it MZMA) and Izhmash.

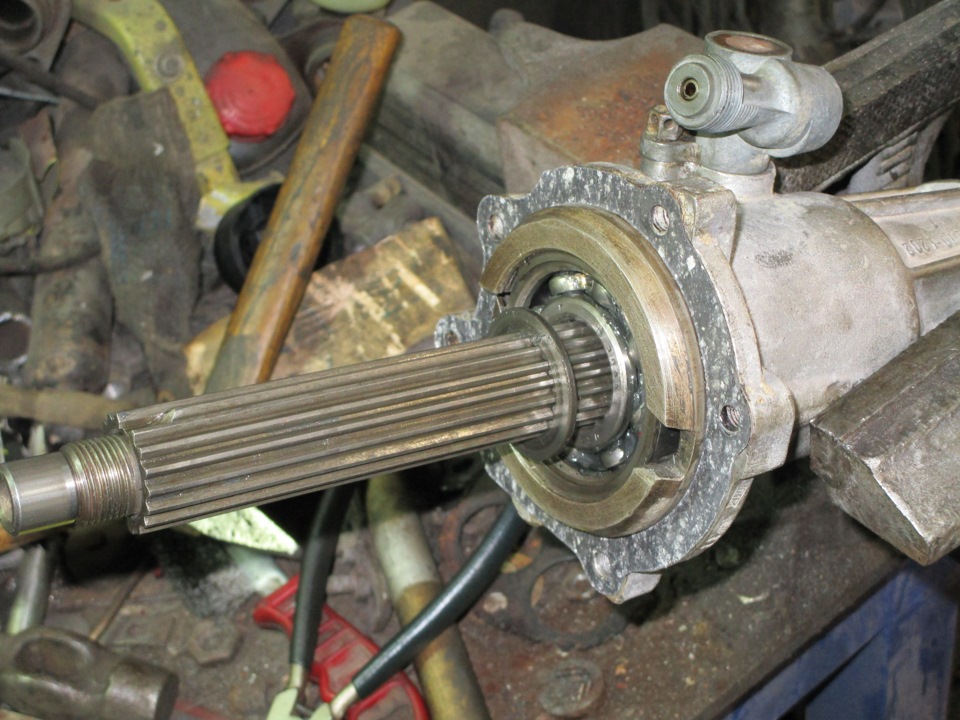

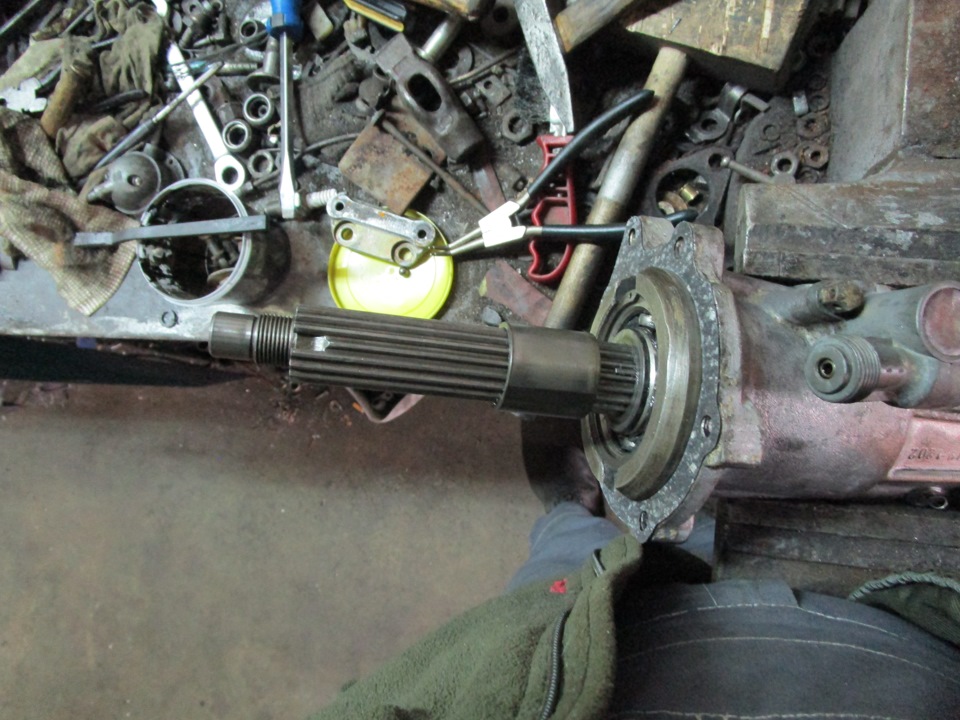

In the rear end udlinnitel transmission when replacing the oil seal revealed the absence of the second, inner seal, but instead it is a factory, labyrinth seal, just like in the old two-stroke motorcycle engines!

The 60s were a time of plastics in the tail we see a polyamide shaped ring — labyrinth seal

The 60s were a time of plastics in the tail we see a polyamide shaped ring — labyrinth seal

As I mentioned, the number of the transmission — 245, which is clearly seen on each gear. Electrogram room copied on all critical parts.

Movable gear of the secondary shaft, primary shaft and gear unit one set, it's not even malomerice is custom-tailored!

Movable gear of the secondary shaft, primary shaft and gear unit one set, it's not even malomerice is custom-tailored!

...but the state of the internal splines of the clutch synchronizers are not pleased from the point of view of pollution. Even the bronze ring even after repeated washing in caustic soda retained the bark from nigral thickness 0.5 mm...

The internal splines of the clutch 3-4 gear crammed bark nigral

The internal splines of the clutch 3-4 gear crammed bark nigral

The difference in the performance of the early and the later clutches are well visible on this photo:

Left — new, right — the early clutch 3-4 gear. Next on the left — washed bronze ring and three dirty.

Left — new, right — the early clutch 3-4 gear. Next on the left — washed bronze ring and three dirty.

In fairness — it should be noted that neither the clutch teeth or teeth bronze rings or, even more gears, sharpness is not lost, chipping and damage had not, but... Time, humidity, degradation of nigral and moisture, which affects all played their destructive role, the bronze rings had to be replaced due to wear and tear notches on the inner cones and the outer cones of the gears clean from corrosion using abrasive paper grit 1000. The new rings sit right, straight and pretty tight. Most were worn bronze washer to prevent axial play of the promval, was replaced by a new one because of the deep concentric nicks and scratches.

Top new, bottom old thrust washer promval. Of course, you can squeeze the tab and turn the old washer, but was new. Put it...

Top new, bottom old thrust washer promval. Of course, you can squeeze the tab and turn the old washer, but was new. Put it...

Impressed and the quality of early forks gear shift!

To the right is the old one. Comments...

To the right is the old one. Comments...

Different and probbaly, executed in the form of blocks of gears with permanent crowns gear. Opening for circulation of lubricant is located at the old shaft differently old tree — dark.

The surface finish of the radii of the fillets and hole location lubrication will vary radically. Next visible soiled and a loose bearing of a secondary shaft 306. Replaced by 306К 3rd GPP with the mark Made in the USSR!

The surface finish of the radii of the fillets and hole location lubrication will vary radically. Next visible soiled and a loose bearing of a secondary shaft 306. Replaced by 306К 3rd GPP with the mark Made in the USSR!

On the yellow lid from a can — small parts, including the locking prism is very small size, even the ball for fixing the forks seem very large in comparison.

Retaining prism sleeve gear, secondary shaft, crackers and ball. Who less?

Retaining prism sleeve gear, secondary shaft, crackers and ball. Who less?

It is time to collect back. First installed in the shank of the secondary shaft with the bearing 306 and retaining ring:

Immediately put on the washer!

Immediately put on the washer!

Then grease put arbitrarily lock the prism:

Prism is visible between the slots vervale, without changing the position of the shaft wear the bushing of the first gear.

Prism is visible between the slots vervale, without changing the position of the shaft wear the bushing of the first gear.

To clarify — the next photo in line with the question from the previous material:

Sleeve all gears should get eccentric samples of the prism, which prevents rotation of the sleeves at vervale.

Sleeve all gears should get eccentric samples of the prism, which prevents rotation of the sleeves at vervale.

Next — putting it all verbal the sequence and orientation as gears and hubs couplings. Tighten the lock nut and contrib it by folding the edges of the washer:

Fortunately, the front end of the input shaft in perfect condition. Noise should not be!

Fortunately, the front end of the input shaft in perfect condition. Noise should not be!

Finally — a photo of the Assembly after the repair:

What could be better than a new transmission? That's right — old Indochina, the first release after my intervention!

What could be better than a new transmission? That's right — old Indochina, the first release after my intervention!

Need to be filled with grease, to accelerate rotation of the input shaft and is a wonderful vehicle, really — one of the first, will run again in the native transmission, surprising and delighting all.

Yes. Photo made larger, to see the condition of the parts when the mileage 95ткм(!) and easy with the shitty lube for a long time in SPb-shny climate.

Don't spare the grease. Nothing wrong with the build its using, the main thing — not to lose any needle.

...it is easier than ruining the family cars... Practice to start on a down and out late in the boxes, though they are relatively a lot more.

The fact that the oil is not terrible, terrible is when oil is overcooked and its not enough...

Your articles about units and aggregates — excellent tutorial! A good benefit in our day — a rarity!

Margarine — a substitute of butter, and a Muscovite — a real car of good materials. Rear crashes from nevklyuchenie and chipping of teeth at the ends of the two.

412 margarine my first car, I remember constantly tormented with flying reverse nostalgia.

Thank you for the interesting educational program, not overloaded with unnecessary technical details.

Yes. In the compartment 412, "One of the first" in 408th appearance and with round headlights, solid sofa and a control transmission on the column. The rating is next to Yours!

For Museum sample, of course, everything should be done on the highest level.

And on this online car present? It would be interesting to look at it.

Thank You, Daniel! I do my best to keep the original, fortunately in this case it was more than possible! Well, the responsibility — after all, the car is marred, extremely good and belongs to a decent man. And given its rarity and overall condition of the Museum sample.

Thank you for the kind words, just to clean out the old silverfish was the objective. And as everything divine was inside! Now bare metal.

Chugoku need to paint it

as well, respect

always pleased the eye, when it "rises from the ashes of the" old technique

Point — like in the book. Maybe the scale key left, don't remember. Strip all wanted old put, removed them carefully. But the new changed the course of the work. Thanks for the correct perception of the material!

Quality parts and Assembly at the highest level! Go ahead and continue to delight us with such informative articles! After reading your article, I wanted a direct replacement to disassemble the box :)

"Tighten lock nut" what is torque?

Toothbrush everything, also repeatedly rescued when washing parts, it is convenient to crawl into tight places.

When assembling the gaskets put on dry? Possible to soothe the soul very thin layer licola their fluff?

well then that's cool

we are stoked items is relatively long in the container with solution for a couple of hours at least.

by the way, can be short-term and Lumina dip to "refresh" item to the "white-matte" look. But it is important to take steps to not get eaten by the landing bearings, etc. where important the exact size.

Then, just in the jets of the reagent and washed everything at 60 degrees. Won — seen, nonferrous metal a little darkened.

Yes, here's another thought:

organic compounds are very well eating alkaline. You mentioned caustic soda. She is quite weak alkali. To help her you can, spreading it with boiling water, and the solution was very hot, pre-heat and soak the details. To the solution is not cooled and more fun ate g@VNO.

We used them in the production of caustic soda in liquid form in high concentrations (hovering in air). It is very well corrodes organic matter (fossilized oil, paint, resin on the cutting tool, etc.), and does not react with steel. The only lye should never be dipped metals "to the left on the periodic table": Lumina (and alloys) zinc (and alloys), etc. will Eat.

Thank you, it's not my BJ or in this case someone else's car, it is rather — comparative analysis early late. As for instructions — completeness is not intended, rather — addition to the knowledge of those who to some extent understands. Personally, I was impressed with the design and safety of entire set.

Well done! The desired entry in BJ, and excellent instructions, even for experts will find something new.

Yet, You think and make a list, will gradually close all consistently. This is a kind of joy of restoration lies!

Thank you, started with dad to disassemble. Well, it is in the course zapchasti a new — wings, radiator, on the chassis...

Now as a bridge to roll out I will change it back to the old one.The old podshipniki tired

I hearts...But did while temporarily of course, though it is included...In the new transmission oil top up-problem.

Edgar-MG

Oh, that would be another review of the CP-9)

By the way, this box in Moscow is, only whether its a review, question...

www.drive2.ru/l/288230376152716311/

Mikhail67rus

Yegor Yegorovich, there is one person in Moscow 412-020 box. You can try to talk to him, suddenly give a review :)

www.drive2.ru/l/288230376152716311/

Ready in PM to discuss if there is someone ready to take up the bulkhead

I understand the interest in the topic unsubscribed. Not sure that someone will bother.

Yegor Yegorovich, there is one person in Moscow 412-020 box. You can try to talk to him, suddenly give a review :)

www.drive2.ru/l/288230376152716311/

...or, in science and in accordance with the Homologation — 412-020! I'll think about it. In the hands of the present, but there are some reports and documents.

Please open it and write anything with the preservation and improvement of health in fact the reverse of Assembly!

Right. Special works will not be in parsing, the main thing — to monitor closely the safety of all the details, especially love the beads and the needles to escape forever...

Enough and one. But without fitting and Assembly skills and spatial thinking even should not meddle...

as at the time my father said

will deal a couple of boxes and understand how to assemble and disassemble that it would work

No ball joints there is not, strictly — standard, but neither the gum nor the sleeve 67, the year has worn away...

It seems to me — or both control levers — instead of the standard bushings — ball joints? Or is it purely a feature still details to stalk the scenes?

Thanks, I would like to know, in order to collect the most good (though with some limitations) in all respects a set of units on your car.

Exactly! The groove in this version gives the relative freedom of movement of the sleeve on the shaft, facilitating the operation of the synchronizers. In the late — Yes, the sleeve is immobilized by landing on slots, but in the medium — slots for cling pins placed in the radial holes on the side surfaces of the bushings, but at a height not protruding from the body bushings. Sleeve also obezdwijivanie these posts, but the load on the bronze synchromesh rings at high angular speeds increases. In particular, therefore requirements to the oils in these boxes are quite large.

So that's why these grooves. Sleeve inside smooth and prisms are fixed :) In the later boxes of the slotted sleeve.

In the sense of a large current to apply a base, then, of course, and heat treatment would not hurt.

really interesting to find somewhere in Ukraine new plugs a couple of shovels? and then I went through all the plugs and in a sad state especially 1-2 gear

Despite the fact that everywhere has its own orthoepy, and wrong name and pronunciation of terms often distort the meaning. This — the inability to Express thoughts in a proper technical language. Many sin-with...

Excellent article, great photos. That's just-and here orthoepy, the science of right pronunciation of words?

Is and crackers breaks completely... Who could have thought that the design of synchronizers Borg Warner, designed for 2-3 tons about\min from the 30's still will twist 7-8T about the\Ming in the new century?

Good machine! Owned in the ' 90s, only not a Suite, just had to disassemble the box, the reason — burst all synchronous.

Your uncle — kettle. Hence, the panic. + the mentality of the Russian people, all knowing and able for the others, but nothing on their own, here You have tales of gusli-samogudy, tablecloth-Samobranka, stove-self-propelled. Ends this list is very sad. The curtain — this shower curtain in the theater, where on stage all baskovich and Tsiskaridze release, and the fact that You call — control mechanism. Millions of people went and didn't complain, perhaps with some adjustments made friends better than Your family member.

Then, I remember. like the guy panicked when I am in his 412-m Muscovite pulled the transmission. I then learned that scenes from them were shit, and the lever buggy. By the way, compare ideas in different cars.

The days of our hell of the auto industry ended exactly in the 66th year, when was signed the "contract of the century" and the circulation was pushed to the second or third plan, the development of new models and introduction of new technical solutions aimed at improving the quality of the final and most important product of the car — drive. As for the transmission designs of automobiles Muscovite, equipped with motors 412(a material — it is about them, not about our achievements, now lost to the industry), the real — konstruktiv improved, the sizes of observed, the node is fully consistent with its purpose and fulfilled all the requirements. Another thing — casting of the crankcases and liners sometimes radically different from this instance, but the dimensions and materials of all viscera was at the proper level of quality. But in order to talk about "normal cars" — you have to ride a dozen other cars in the same class from different manufacturers and be able to distinguish ideas and their implementation from packaging and trendy now triumvirate (environment\efficiency\security). Remind, the final product of the car is to drive...

That's why we have the whole auto industry sucks. On paper everything correctly, but will begin serial production, drunk Uncle Vasya driven hack, though not without the help of the authorities, requiring the implementation of the plan. That's why we do not have normal cars, though, and know how to do.

Prepare the mating surfaces before Assembly. Total clearance, torque, landing bolts on the threaded glue — that's all of difficulty, but you can do without it. Tighten the bolts need crosswise.

you know if you were geographically close... you'd get it repaired. I AZLK transmission do not know and therefore do not climb there and to me these nuances of the unknown. can share a secret how to stop this fucking heat? I'm already seriously considering replacing it for the WHA checkpoint. 4 years in the field on this from went never any leaks present.

Because it is necessary though sometimes to monitor the status of RTI is linked to the side of the lid, and — as ACSR sleeves, Talabani or, if earlier boxes.

well, if you are an expert on 412 box tell us why these boxes are often subject to protekanie oil?( from the shank and side cover) how to deal with it?

The main thing is to be clear about what one wants from a car. I want to ride, you ride, you want to modify — modify and go, and pleased with all that in mind, the designers, and I have translated according to their needs.

I also understand you want to your car masakorala. I tell you why. no one in the town will take to fix my native box someone it doesn't know and who simply spits not want to do. with VAZ is another matter. I don't like the native cat of its thrust ( like an extra node) do not like long stroke, bad back. of all the master box I did one and it's already flowed out through the cracks like crazy. I will probably look for a stove with cardan shaft and paddle and to remake the classics... especially on vases box it goes on the album

Low quality and a significant amount of rework, destroy all the Ghost perks. Vehicles of this kind I've seen a lot, and then their PR... a Long conversation.

and another question. why the owners of the 412 Muscovites so love to put on their cars 5 mortars VAZ? well, Zap. part clear but if any significant advantages?

Dear RAIDER412, Moskvich 412 in runoff accelerates for 3 rereduce to 130 km/h without consequences for agregatov car.

Because the synchronizers are there from a different version of the box — for a sports car. In the original there is sadness under 110 Nm)

It is possible to expand the details in the description of the repair up to someone the next checkpoint. The design of the whole transmission wazowski shit all the solid rudiment and atavism. Only the synchronizers are still here and there — fit.

It would be interesting to describe and nuance the setting in place of the prom. the shaft — as he first sinks to the bottom of the crankcase box, and after Assembly and installation of the primary and secondary shafts rises in its place. About the intricacies with the positioning axis of this prom. shaft — to not spill the needle bearings and so on.

And all this system with rods control box is essentially a vestige left over from the time when the transmission control lever was on the steering column.

In terms of gear select Wazowski box is much more preferable.

Good time of day.the question is not on topic.but zaranee thank you.want to buy maskaleris 2137 1983 old.sostoyanie good lay for a long time the price of aprosa 10 papers of Franklin.whether or not

If the gear is 38:9 ratio 2140, about the speedometer not say offhand. BUT: as krupnooptovye and fine teeth of a box of differentials and axles was on 408, respectively — gear ratio they had one in the GP — 4.22 — 41:9.

Between the gears there is no difference. The main thing — to keep the ratio the same. There is a difference in gear on the secondary shaft of the transaxle.

Egor Egorovich. Is there a difference between the transmission speedometer gear 408, 412, 2140. Just no banter. I want to change gearbox GP of fine teeth.

Everything is made sleeker, not only the extention cord. But won't the designers, not engineers, and accountants...

Performance labyrinth seal and the seal looks quite elegant design solution, in contrast to the final version with two seals. The latter is not seen any where.

Yes, thank you. I thought about gaps. Interestingly, before looking at the market b/y box — there is a backlash was less than "restored". Assembled, of course, the primary shaft is supported on a bearing in the flywheel, and a secondary fork of the cardan shaft via the sleeve extender. But, it turns out, the more backlash the more "lax" node, the greater the likelihood that it will be howling, etc.

We will seek, as they say. And most likely, you will have to remove the existing box and adefective/repair.

Heating of bearings kompensiruet heat properties of the transmission oil. On the bearings, as a rule, is marked, containing the bearing model and the accuracy class. Ideally, play should not at all: in the assembled state, the transmission does not involve play at all. Clear the values I found neither in memory nor in books, but from my experience I can say — the less the better. Any looseness or entails a noise...

Thanks for the advice. I have great doubt "restoration" — you never know who, where and after a Cup "restored" and how many forces and means will be required for liquidation of consequences. Still allow myself to return to the question of backlash. For example, if I were to do hand end of the input shaft and pochitau it from side to side — how many millimeters is permissible vacillation? In fact, the input shaft fixed almost a console in the crankcase and the output shaft. The bearings have some thermal gap...

Proper and meaningful question! Of course, any "restoration" there is no question. And then: to correctly do PPC don't need a tank factory, for that factory transmission Muscovite — non-core asset. If the end play of the input shaft, and the shaft with bearing from the hand slide out from Carter's wear Carter's. Either surfacing electrode cast iron and processing of the bearing seat, or change the sump. In Your case, neither Carter nor bearing did not change, they BOO. The same is true about the output shaft. Likely — cost opening and the sink, in the best case — replaced the bronze ring synchronizers. To choose a PPC should be exactly the is no play on the shafts, the ease of rotation of both shafts and the explicit triggering of the switching mechanism and visible when rotation is enabled, transmission speed difference of the shafts.

Yegor Yegorovich, and you can question on the topic of boxes? Can you explain "for dummies" how to choose a PPC? Here, for example, offered me a box after the "factory restoration in a tank factory". Pulled the primary shaft end play significantly. In the axial direction of the pulled — bearing tends to leave his landing. Pulled output shaft — backlash there, but less than on the primary shaft. Transfer, like, peresekayutsya. What is permissible? How to check transmission when buying?