Shortening the automatic transmission selector knob — logbook Toyota Crown 1989

I have long wanted a shorter handle, like on more modern cars (for example, the same majesta 14x, in which the handle is much lower).

And when some of the devices migrated to the lower compartment, the desire became even more - the long poker really gets in the way, especially in the parking position.

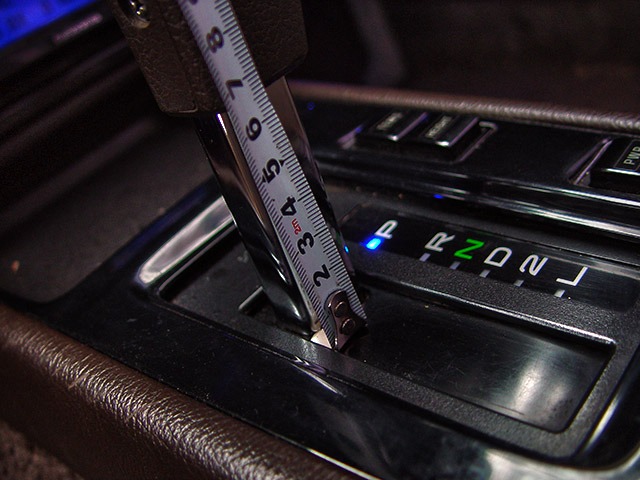

The measurement of the open metal part showed a length of 6-6.5 cm (here it depends on how to measure), and I decided to shorten it by 3.5 cm so that after the alteration the handle would not look short, and the visual difference would not be an eyesore. In addition, if desired, then you can always cut off more.

The first task is to remove the center console. The plastic pad can be removed easily (it snaps off starting from the armrest). Under it are 4 self-tapping screws, 2 more sides (they are available if you move the seats forward).

Then the handle is removed, 2 screws on it are unscrewed, then the plug is removed, and the button is unscrewed.

As for removing the button. Many people have a problem with removing the handle, because. the button interferes, but it does not have a connector in this place. Some cut off, then soldered, I think this is a glitch, if you climb there with a soldering iron, it’s better to immediately put the connector with fixation.

The button can be disassembled, and when disassembled, the contact pad will fit into the hole.

The main thing during disassembly is not to lose the side spring, and not to bend it during assembly.

Next, you need to climb under the car and unscrew (nut by 12) the selector drive of the machine (do not forget to ensure the stability of the car in neutral, and muffle it), after that you can unscrew and pull out the entire selector mechanism.

Such a moment. At the end of 1988, the Yapis restyled the automatic transmission selector mechanism, it became much more complicated, due to the red button that appeared and the inability to pull out the key in any position other than P.

As a result, the mechanism began to look much more complicated, but there are no fundamental differences in the analysis.

Here is how the mechanism of 87-88 looks like:

The removal process can be optimized if you can access 10 blots without removing the handle itself (more precisely, without removing it completely). In this case, you do not need to disassemble the button, because. the overdrive wire can be pulled out with it. I haven't tried doing it this way, but it might be easier that way.

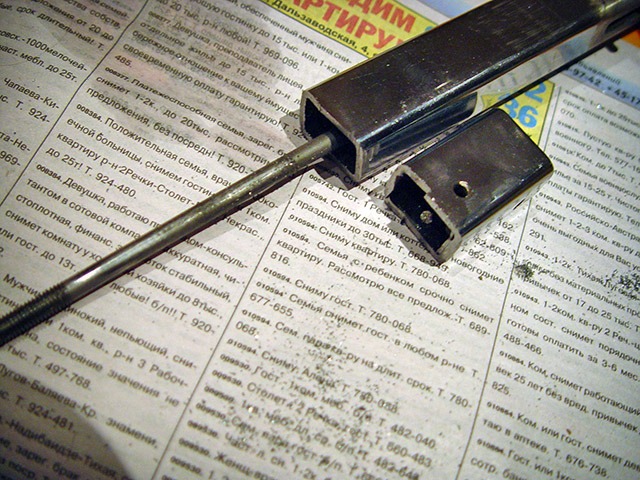

After the mechanism is removed, we disassemble it further. We unscrew the axis and pull out the movable lever itself, which we will shorten. You need to remove the wire from it, this is done by pulling the pins out of the connector (remember their old location, although this is not critical for the button).

After removing the handle, you need to pull out the black plastic guide, which is located in the body of the stick. In theory, the T-shaped blocking rod needs to be pressed out, and then pressed back in. On my knee, I couldn’t do this, and I just hit him from above so that he got out of the guide and she was able to get out. At the same time, it was naturally damaged (at the very bottom), but this is completely unprincipled, its role is only to separate the wire from the stem and guide the stem itself.

The next step is shortening the stick, stem and plastic guide.

1. The stick in my case is shortened in my case by 3.5cm. I didn’t pull the rod out of the stick, I sawed it right like that. If you are sawing with a grinder, be very careful not to cut the stem. If it saw off crookedly (usually it turns out like this), then you need to modify it with a file, trying on the sleeve so that it sits normally.

2. It is better to shorten the stem by 3.0cm (so that it eventually becomes 5mm longer)

3. The guide is shortened in the same way as the stem, also by 3.5 cm. To do this, it is cut into 3 parts. She has no tensile load, so I symbolically fastened her with 2 heated paper clips.

Next, we cut the thread on the stem and make new mounting holes in the stick.

For threading was purchased:

- M5 die

- M4 taps (set of 2)

- Corresponding knobs.

– Drill 3.3

Knowledgeable people told, thanks to them, how it is done correctly - we puff with a vedeshka, go in as perpendicular as possible with a die, and twist - turn forward - half a turn back. The main thing is to do it slowly and keep it steady.

It should be borne in mind that the stem itself does not actually have enough diameter (for M5 you need 5mm), so the thread is a little licked. His original thread is knurled, and we make it chopped.

So I bought M5 self-locking nuts, and used one to hold the spring. All efforts in this case are transmitted through the nut, and so much more reliable.

Although if you left the stem longer, according to my advice above, then you can do without a nut at all.

Next, we insert the sleeve, fasten the corner, put on the handle itself, make sure that this is how it will sit in the assembled state, attach the bunch to the stick with tape, and drill new holes for the screws. We disassemble and cut the thread, only with a rough tap, with such a thickness of the metal it is quite enough.

Everything is ready, you just need to be able to put everything in the reverse order)) And adjust the corner to taste. Personally, I like the preload (the corner is raised higher, the stem is pressed a couple of mm), then there is a feeling that the mechanism with the button works as a whole.

When you put it back, do not forget to immediately install the rod mounting axis on the machine (the lowest part, which is with a cotter pin). I forgot about this detail when I had already assembled almost everything, I had to install the cotter pin lying under the car, and this is very inconvenient.

Actually, here is the result:

What can be done in passing:

1. If you have a mechanism with a selector lock (there is a red button), then I personally have such an unpleasant moment with it. If you try to shift from P without pressing the brake, the button is blocked. But after pressing the brake, the locking mechanism bites, and you have to lower it a little and press it again, which personally always infuriated me. It is solved with a file: the contact surfaces must be set at a small angle so that the force of the electromagnet is enough to open the path for you even under the pressure of the button.

2. When you disassemble, you will see that the selector axis is held on plastic bushings. Over time, they wear out and the handle becomes lighter, this is completely non-lethal, but enough to palpably distinguish an old car from a new one on this basis.

If you put something on the edge of the axle (a piece of electrical tape, a wire braid), or sharpen the central sleeve (the method depends on the version of the mechanism), this will make the selector move more tightly, and the backlash will no longer be felt.

This year it will probably be the last entry in the magazine. I wish you all good luck, success, new nishtyakov and tunes, and money to implement your ideas in the New Year!

Issue price: 500 ₽tnet

Probably to make it more convenient for the Japanese grandmother Tanaka Yakuzovna.

hahahaha you suck!

Respect! Good job! I was always killed by the length of the automatic transmission on some machines)

Maxxeem

Almost like the GZ20 Soarer!

Yeah, at twenty I like the automatic transmission lever most of all))

On the GZ20, the lever length seemed short due to the raised console, in fact, the lever is not so short.

GZ20 is still far away :)

It's funny that the GZ10 has exactly the same poker ...

i257.photobucket.com/albu...6/Meteorite-Rosso/062.jpg

Theoretically, it can be stuffed into a stub. Without a left-handed donor, it's still pointless to start.

Great! must be done while disassembled. And you can make it so that the button on the other side turned out - if you still decide to transfer the steering wheel to the left.

Thanks!

In theory, this is being treated, there is a mechanism - there is a contact group right on the selector, and it only works when the selector is in the parking position and the large button is pressed. I think most likely just lubrication was knocked out, or the selector adjustment was lost, which is why it pulls back.

I also thought about it. And I have such a problem with the machine, you can know what's the matter: when you put the parking lot and turn off the engine, the key is not pulled out of the lock until the machine selector is pushed closer to the ashtray in the parking position, but then the key can be pulled out of castle. For the work done current 5!

Exactly! The radio tape recorder and route manager click with a bang now. But in the configurations with TV there is a regular CD player - how the Japanese missed such a chip is generally incomprehensible.

Yeah, fresh ones are generally miserable. and yours is completely fine)) Yes, and in the parking lot, access to the radio tape recorder has probably become more convenient

OK thanks! In fact, I wasn’t even particularly interested in the appearance (there are worse handles, even on much more recent cars), I wanted convenience - and it was achieved. When I turn on D, I remember that the efforts were not in vain, and my heart is good!

But there, usually, the limits are more serious than just shortening the handle. As I understand it, they are trying to shorten the course, but just a short handle is not even a show-off.

yes, the whole procedure is much easier on fur! I removed the gear knob for 1-2 minutes, took a small grinder for 1 minute of work, and put a new bunch of gearboxes for another 1-2 minutes)))

I agree, well, imagine such a picture, you get behind the wheel of a normal car, and there, from the backstage, this crap sticks out half a meter, would you like it)))?

This is what it means - "Hands grow from the upper body." I thought about it, but I was afraid to climb there. Now, with such a manual, you can try ))))) Huh. Well done !

It is necessary to rearrange the entire mechanism, tk. the restyled metal lever is more rounded, and the new handle will not sit on the old lever.

did great! I've been thinking whether it is possible to put instead of this another handle from the same crown only round. I like her better this one makes him look older

As I noticed later ~ 4 cm is the limit, in the L position the handle rests against the console already

well . what can I say ...)) the DVD has been working for Mayfun for more than 4 years, the fan - I don’t know, I can’t hear it)), Yes, sometimes it doesn’t read, I don’t know why, Yes, the fact that Tags does not show this is a minus, and there was no volume pickup from the very beginning … everything is possible, even the fact that China and I have, but I'm happy. ))

To be honest, the mafon sucked: The fan died, then the DVD drive. Sucks out the battery ... and if you forget a flash drive in it, then generally in 2-3 days. Some MP3s do not play (sometimes there are such among 320), instead of sound - a crunch with signs of the original. HF are overwhelmed, strongly. Tags does not show at all, only numbers. You can't switch between albums from the muzzle. The volume is adjusted with a nasty beeping and it can not be cut down. Uneven illumination (I had to glue the LEDs on the encoder). Etc... All because it's not a JVC 617EE but a Chinese fake :)

Now I changed it to less, but the truth is it costs an order of magnitude more expensive.

Even on the teapot I dreamed of doing this, but I was afraid, and here is such a visual aid! Thank you very much! Very soon I will take care of my stick)))

I also think nothing should change much, it’s just that I read from someone that switching has become tight ... so I decided to ask ... I’ll also cut it a little warmer)

Well it's automatic, there is a minimum effort to switch. A 10% change in leverage is not perceptible.

And I like everything spatially, it’s better to lay down your hand. And after a week, if not earlier, it begins to seem that it was.

How does it feel after you shortened it? Does it switch the same way or does it become harder to switch?

cool. on the contrary, I need to lengthen the lever due to the high tunnel in the center of the console. but still thinking

beautiful) I always shortened all my models, but there were all on the mechanics. Right now on the Mondeo automatic transmission. Maybe experience? Tell me.

there it is technically possible to connect to a spit that goes from the machine to the scoreboard, and do the same in the machine

How did you make it glow blue? In the same place, the red overlay moves with this plate.