Breakdown — logbook Toyota Corolla Levin 1997

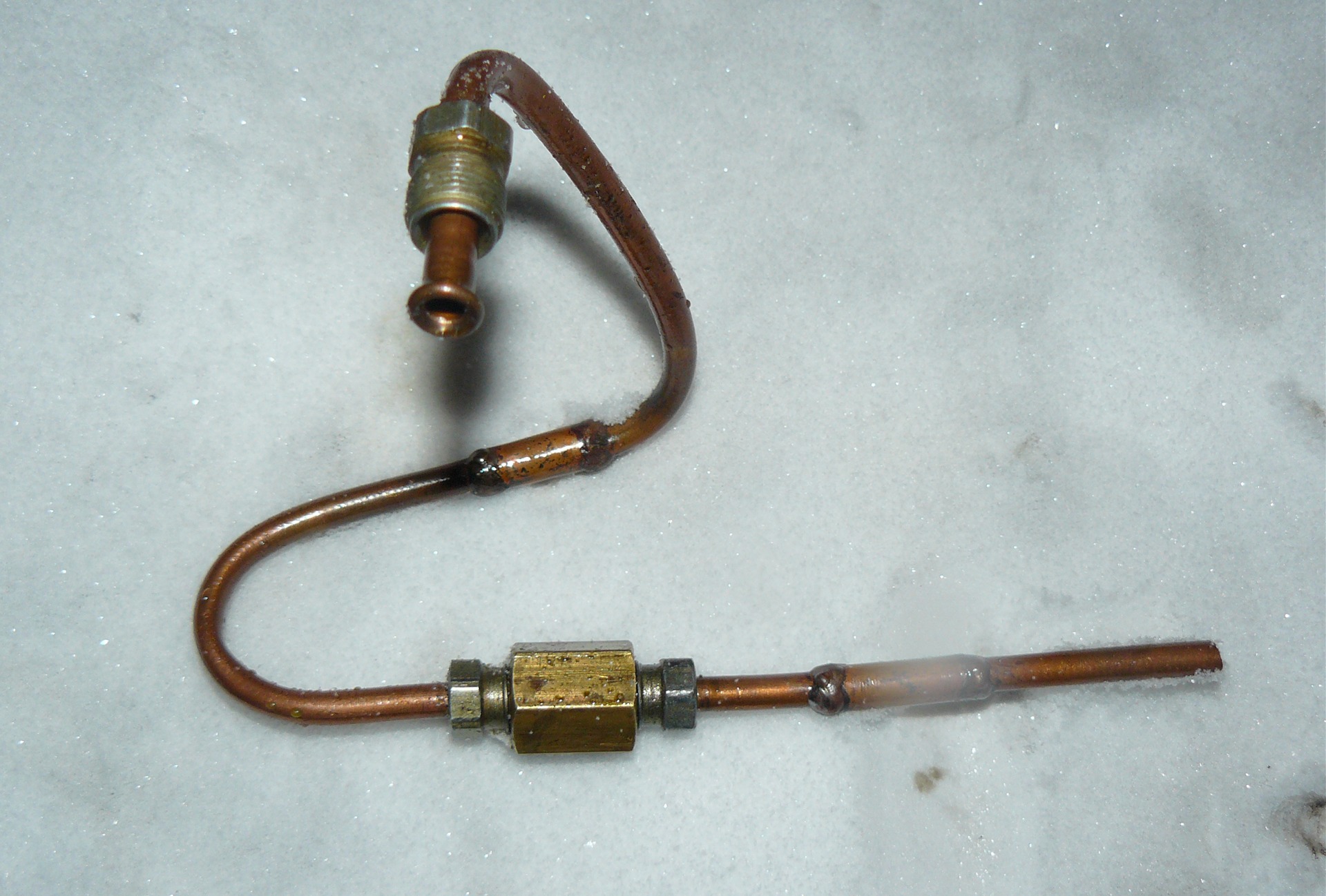

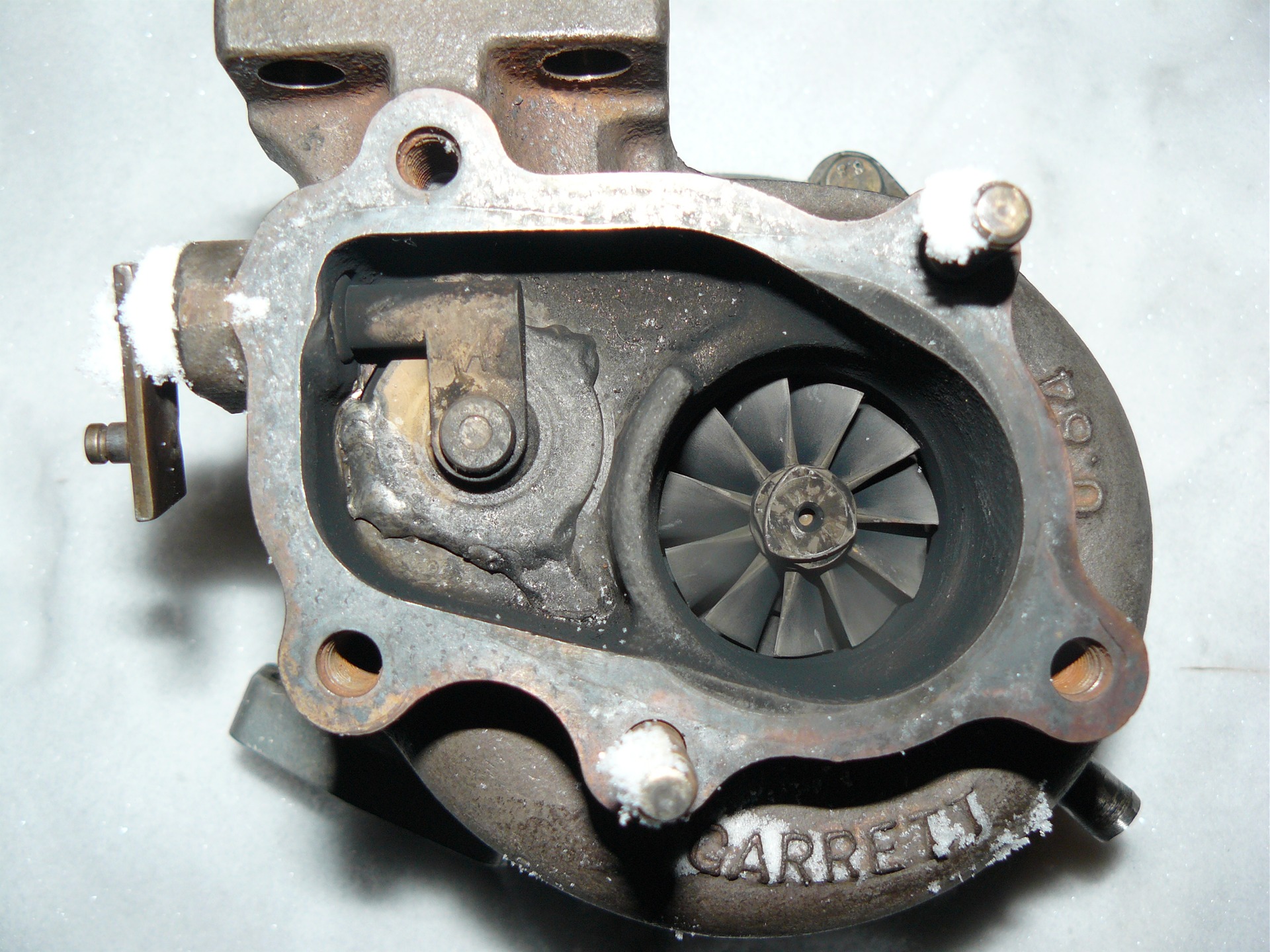

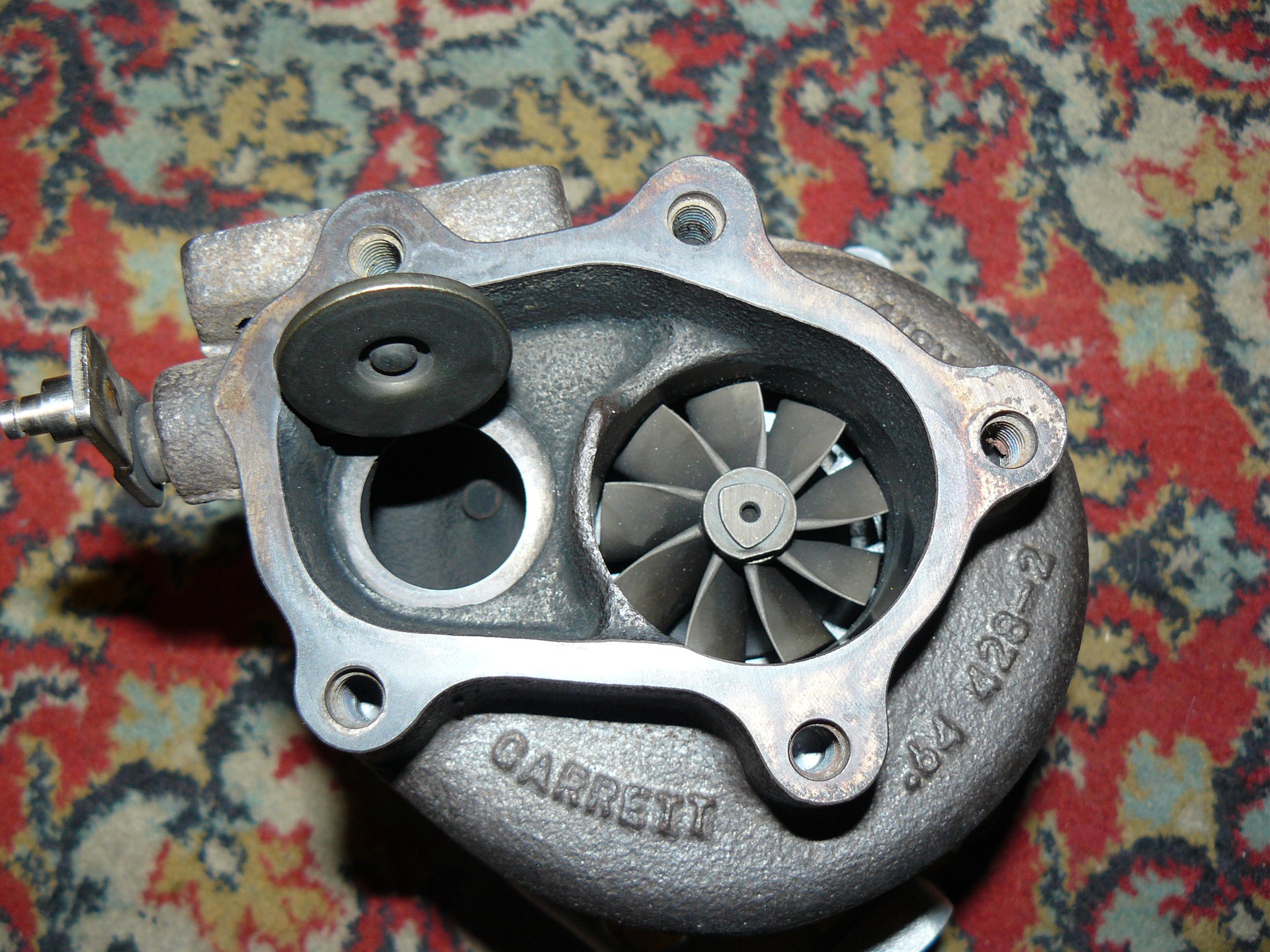

Good day. Today, a terrible thing happened, the oil supply pipe to the turbine burst. I discovered this only when the oil pressure control lamp lit up. Fortunately, I didn’t drive fast. Now everything is covered in oil under the hood. The mood is not very good. There was a reason to change this turbo for a Garrett 2871RS. Here is now another night without sleep))). Here is a photo of the tube, the old turbine and the new snail))). I want to know your opinion.

Edit

AAAAAAAAAA. Damn. I didn’t read your comment carefully). And the tube is like that because it’s not convenient to unscrew it from the turbine. Just in case, I did it. There is not enough space behind the snail.

Why out of several? These are 2 different turbines. The one that stood on the top. And I think to put the bottom one or not.

harnyayaya))

why is the tube so flawed, cut from several pieces, you need one, solid, good

the main thing is that it be oil resistant. If it is not stable, then it will quickly harden and crack.

But such a question, we put a reinforced hose from nitrous (nosovskaya), how will it be?

the engine did not start, I think on the topic.

I will post later in the report on the forum ... how they did it ...

The snail is whole, What will happen to her, this is iron))). Oil ran out through the tube (((.

which one do you want to take? and with this one, I thought the oil came out through the tube, but the whole snail remained

but for now, I would collect it on this one, but if you find a new one, I would take it

On the old one, it can be seen that the turbo with a bad zero worked, the impellers were cut. Change the filter or you'll ruin the new one. Although I may have already bought one.

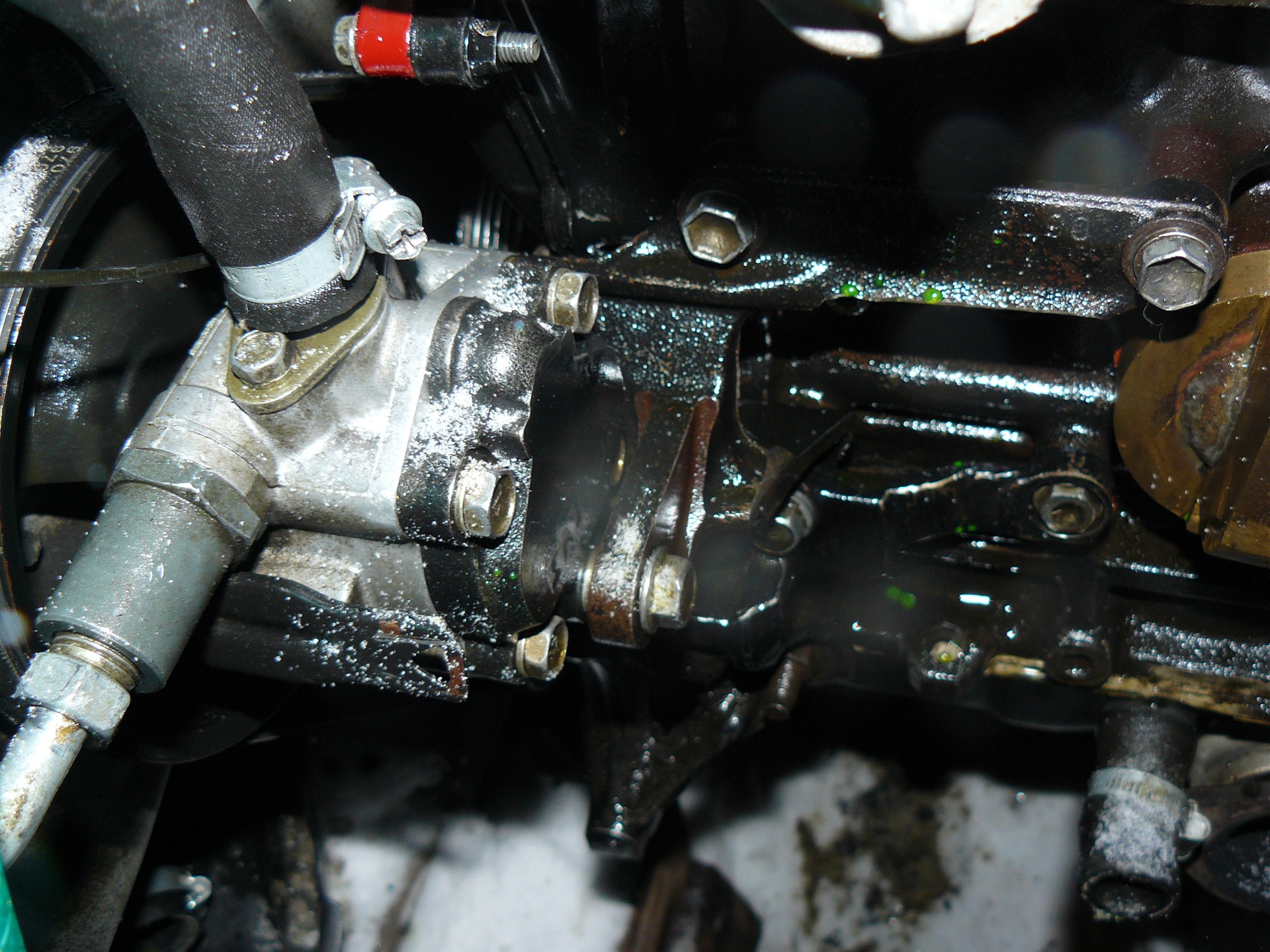

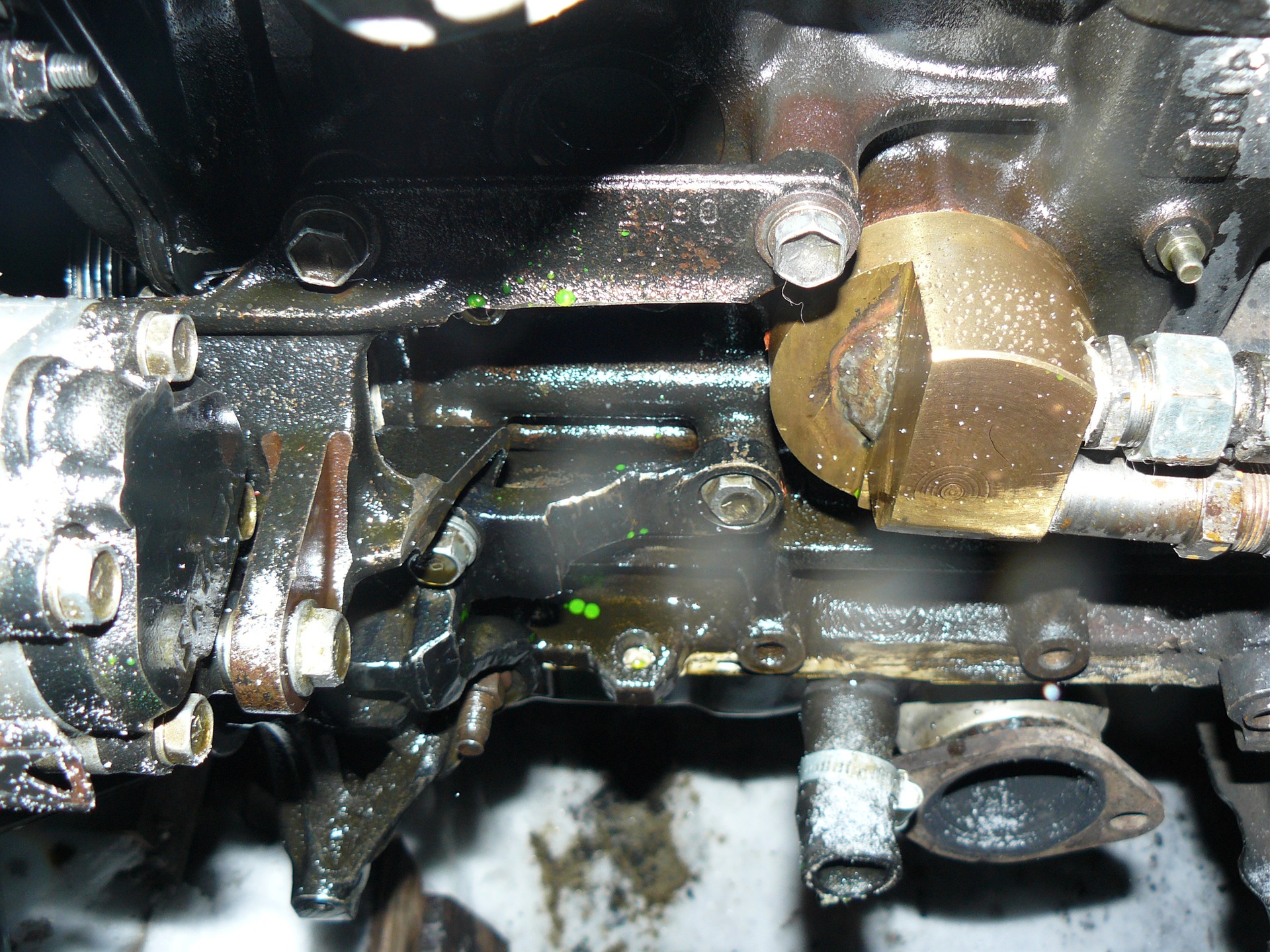

on the Nissan turbine it was unnecessary to brew the built-in gate, because maybe that's why it staggered. It is also advisable to use a drain restrictor in the oil supply. draining into the crankcase above the oil level, and not into the sump)

we have been working with an ear-shaped stock turbine at 0.7 kg for a year now. blew at times and 1.5kg on the 25th Harry.

good project. also wanted to blow out 4a-fe)

I have the 25th harry from the silvia in the 13th body. They were sleeved. Ball capricious to oil, to cooling, overgrown with shit and wedged. Therefore, probably, the soul lies with the bushings. The ball has one small +, this is an early boost. The same can be achieved with a non-sleeve with a free outlet route.

Now a friend wants to remake a ball-and-socket one.

that snail that in the photo it has a very high mileage. it’s not clear how they drove it before me. I just showed it to local craftsmen. I was told that it would be repaired. but as it turned out that the ball was not repairable. she only left for 2 weeks. you were just lucky)

then the reason for the rapid death of the turbine is not clear. Turbines with a remote gate have a non-aggressive configuration of the hot part. I just assumed that the hot part overheated and burned the oil on the drain in the cartridge.

ps — maybe I just got lucky with my snail.