How do lubrication

Today I will show you how to develop, test, and manufacture grease on one of the enterprises in Russia.

A modern car is an ideal field of application for lubricants. Different conditions of load, temperature — all this requires component manufacturers to use different greases. Not just liquid, like motor or gear oil, but grease, or whatever they are called, plastic.

Such lubricants are applied to the nodes on which service seldom occurs inside the different assemblies, C. V. joints, brake calipers, and so on.

Before we move on to the production shops, talk a little bit about terminology and about what, in fact, doing the greasing.

What is grease

Grease is a lubricant, which depending on the load may exhibit properties of both solids and liquids. At low loads it does not lose shape, no draining from vertical surfaces, whereby its retention in unsealed friction.

At loads that exceed the tensile strength, grease acquires the properties of a viscous liquid, helping to reduce friction and wear of the node. Upon termination of load, the grease is returned to the initial properties.

What is lubricant

Not so long ago the main components of greases were animal fats, in particular, the best grease made from the fat from the head of the sperm whale. Today, technology has made a step forward.

In the base greases lies oil (mineral) or synthetic oil. Its share in the lubricant composition may be 70-90%. Thus, the “base” is very important — it directly affects the main characteristics of the lubricant.

From 8 to 20% mass fraction accounts for the thickener is a kind of “sponge” structure-forming component, giving the grease the required physical properties. As a thickener used complex or metal soap (e.g., sodium, calcium, lithium), inorganic (silica, bentonite clay, etc.) or synthetic thickeners (interattraction, polyurea, etc.).

In addition, the lubricant composition includes additives, the composition of which is determined by the purpose of lubrication. First, the additive (similar to motor oil). Further fillers to improve certain properties, such as sealing and anti-friction (for example, graphite, molybdenum disulfide, titanium oxide, copper powder). The third type of components of the lubricant — modifiers of the structure that affect its strength and elasticity.

The composition of the lubricant determines the key parameters of its quality. Among them were the dropping temperature, shear strength, penetration (penetration), viscosity, corrosiveness, mechanical stability, volatility, water resistance and so on.

As you probably already guessed, the exact composition of the lubricant, her recipe — this is the main secret of any company that produces lubrication. Today we will visit one of such industries located in Saint Petersburg.

About the production

Scientific and production company “vmpavto” was founded in 1996. Currently, the company factory in St.-Petersburg annually produces over 1500 tons of greases.

In addition to retail and wholesale chains, the lubricant is supplied to the conveyors of automobile factories, for example, enterprises of GAZ group for the Assembly of axles and axles of buses PAZ, LiAZ, KAVZ, GolAZ; and "BelAZ" for the Assembly of dump trucks BelAZ-75131 (g/p 130 tons) and BelAZ-75600 (g/p 320 tons).

Besides the automotive lubricants, the company produces special products, such as the first in Russia started the production of lubricants for modern tunnel bore complexes. In addition, the company produces a line of industrial cleaning products “Chistik”, additives for oils and car care products.

The company that is certified according to ISO 9001:2008, has 110 employees. Working conditions make a good impression — a well-lit, clean shop, clean toilets, a gym, a masseur, like restaurant dining, a real greenhouse in the office.

Now let's see how the light appears a new product — grease.

Development of lubrication

Development of lubricant takes place in the laboratory of scientific Department. She engaged chemists-technologists and engineers-tribology. Their objective is to create a product that meets the specified sales parameter that, depending on the lubricant, differ very substantially.

The components used are mostly imported, production Japan, India, Germany, USA and so on. Technologists lament — in Russia the production of chemical products is reduced every year, synthetic oil is not produced. Of the solvents there are only four types, and in Germany alone kerosine — 20. This is why, to get the quality product you have to buy imported components.

Since the synthesis of lubricant — is a series of chemical reactions occurring at different temperatures for brewing the test batch lubricated with a small reactor.

Control — automatic, with touch screen. All settings and monitoring process is available online from the workplace of the engineer.

Heating, cooling, passing the colloid mill for homogenization and then two days later a sample of the new grease ready for testing.

Testing lubrication

Testing are subjected not only to the newly developed lubrication, but also samples of each product batch each product. The specimens are kept 5 years warranty storage period — first 2 years in the lab, then another 3 years in the warehouse.

Thus, it is possible to take to counter any kind of packaging, its labelling to identify the party and to check its settings as needed at any time. Testing is to ensure that the lubricant meets the requirements of GOST and TU on the declared characteristics.

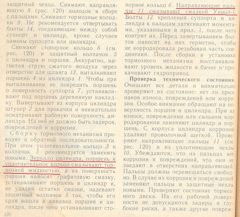

The first measured parameter is the depth of penetration. It shows the plasticity of the grease, how easy it is amenable to deformation. It is an indicator of such physical properties of lubricants like viscosity, fluidity and elasticity. Because different sites require different mobility.

Penetration is tested at 25 degrees Celsius and is measured in tenths of a millimeter In the series — three tests. Permissible deviation from the standard — no more than 15 units.

The following test titration, to test the acid-base number of the lubricant. Lubrication should be neutral so as not to cause corrosion of the rubbing surfaces.

Full sizeIn the first picture — titration. Hereinafter, the apparatus for measuring the drop temperature, samples of the greases. Hereinafter, the cooling chamber, in which at the moment are tested in different liquid Gur. The last picture is the stand for assessment of the effort made to unseat the wheel bearing.

Full sizeIn the first picture — titration. Hereinafter, the apparatus for measuring the drop temperature, samples of the greases. Hereinafter, the cooling chamber, in which at the moment are tested in different liquid Gur. The last picture is the stand for assessment of the effort made to unseat the wheel bearing.

Another important test is performed on the device to determine the drop temperature. It takes a special cell, it introduces lubrication. A cell has a bottom opening. When placing cells in the chamber at a certain temperature the grease starts to come out, and the automation determines the dropping temperature. This index implicitly determines the conditions of application, for example, the maximum temperature of the node.

Test of main tribological characteristics is achieved by using four-ball machine friction. Here is measured the critical load bearing capacity of the lubricating film between the friction pairs (the higher the better). In addition, the load welding, which can evaluate the extreme pressure properties of the oil. The fact that at higher loads, when the oil film breaks, take effect extreme pressure additives that reduce the coefficient of friction. That is, the wear and tear is present but there is no transfer of metal from one surface to another i.e., is not welding.

Full sizelower balls in four-ball machine fixed still. The last photo is an example when there was a welding of the balls under load.

Full sizelower balls in four-ball machine fixed still. The last photo is an example when there was a welding of the balls under load.

Wear characteristics are evaluated by the wear scar diameter on the result of the time test for a small load. In General, all practical tests on four-ball machine friction is carried out according to the size of the wear scar. This indicator is measured with a magnifying glass Brines. Goods, magnifier, weights, a stopwatch, and the machine itself require annual verification.

The measurement of the load, the welding occurs within a 10 second test at maximum load. The load depends on the type of lubricant. For example, the maximum load for licola — 141 kg, for grease МС1000 — not less than 282 kg, and for special lubricants for open gears of shovels, more than 400 kg.

Thermal camera helps to carry out low-temperature grease test. Another test conducted in the chamber, is designed for special lubricants. It is a measure of pumpability, is relevant to mechanisms with a system of centralized lubrication. Previously in such systems, depending on the season, required the use of different oil viscosity, but recently the company has developed a grease of class 2 consistency, ensuring the pumpability of such systems down to -50 degrees Celsius.

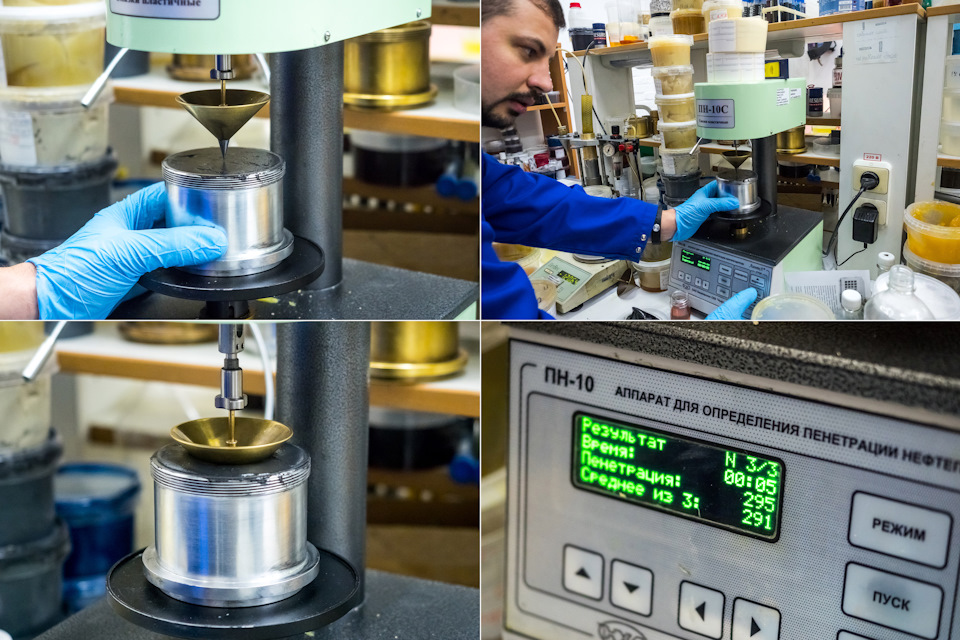

With the help of rheometer studied the properties of liquid, pasty substances, such as viscosity at different shear rate, yield stress and flow curves at temperatures from minus 30 to plus 160 degrees Celsius. Thus, the Rheometer allows to simulate the behavior of lubricants under real conditions at different loads and temperatures.

Another instrument designed to measure the low-temperature moment of breakaway of the wheel bearing. The hub is frozen in the freezer for 5 hours, then with the help of load cell recorded the force breakaway.

Another important tool is an automated machine friction AI 5018М designed for testing of additives (additives) in oil. This machine allows you to simulate the friction between the material of the cylinder wall and piston ring.

The role of the cylinder walls play iron rollers, and the role of the ring — part chrome-plated top piston ring. The point of contact of the friction pair is fed dosed oil. The graph on the screen demonstrates that if you use oil with the additive is a significant reduction of the friction moment and temperature in the contact zone, and the duration of this effect is still additive in the oil will not work.

Industrial production

The production cycle begins on the eve of production, when the operator using the computer system selects the recipe of lubricant from the stock automatically ordered in the right quantities necessary components.

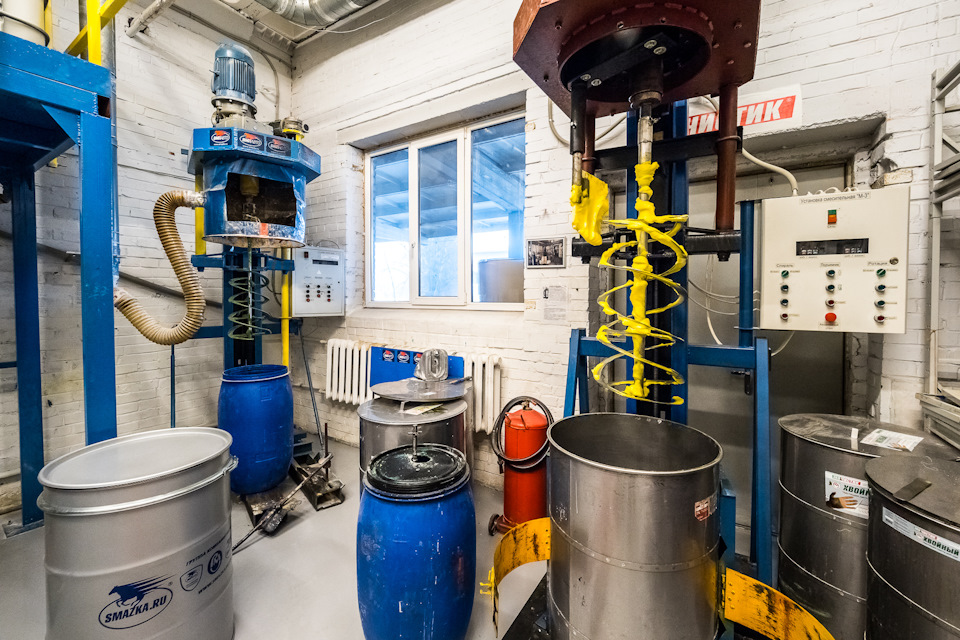

Further, the components supplied to the synthesis phase, where the reactor comes the actual “cooking” the grease, its saponification, and homogenization. The production has two reactors, one for the dark grease, the second for light. The volume of each 10 barrels of production. Components in semi-automatic mode are loaded in the reactors (part — pump part manually).

Full sizeHere are the reactors

Full sizeHere are the reactors

In the reactor maintained the temperature cycle, which is fixed with the help of computers. The display is not only a temperature cycle, but the necessary components. In reactors with a plurality of heating elements is heated, a chemical reaction and cooling (in the “jacket” of the reactor coolant).

net/2c394eds-960.jpg width=960 height=320 itemprop=contentUrl>Full sizeDownload reactor top. To the right is the control panel.

The process of synthesis of lubricant takes two days. Then the finished product at a temperature of 100 degrees Celsius homogenized in a mill and discharged through the hoses to the barrels.

The synthesis of lubricants is completely computer controlled. All the data of the production cycle are available online and are stored for each batch on the server.

After synthesis, the barrel with the base lubricant or sent to the warehouse, or, if in the future there will be a special grease, it moves to phase mixing. Then using the mixers own design is the mixing of additional components.

Full sizeis One of the parts of the mixing

Full sizeis One of the parts of the mixing

Some of them can be in the form of “dusting” of powder, so these mixers can be equipped with additional covers and hood. Nearby furnaces, which are supported by different temperatures — some components must be added at high temperature.

After the batch is completely finished lubricant into the shop filling.

Packing

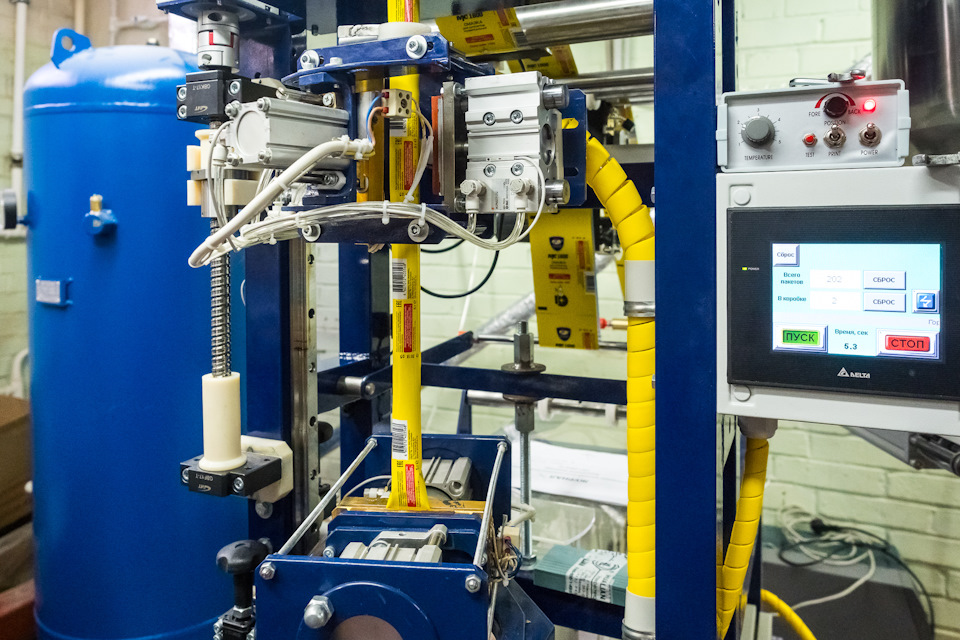

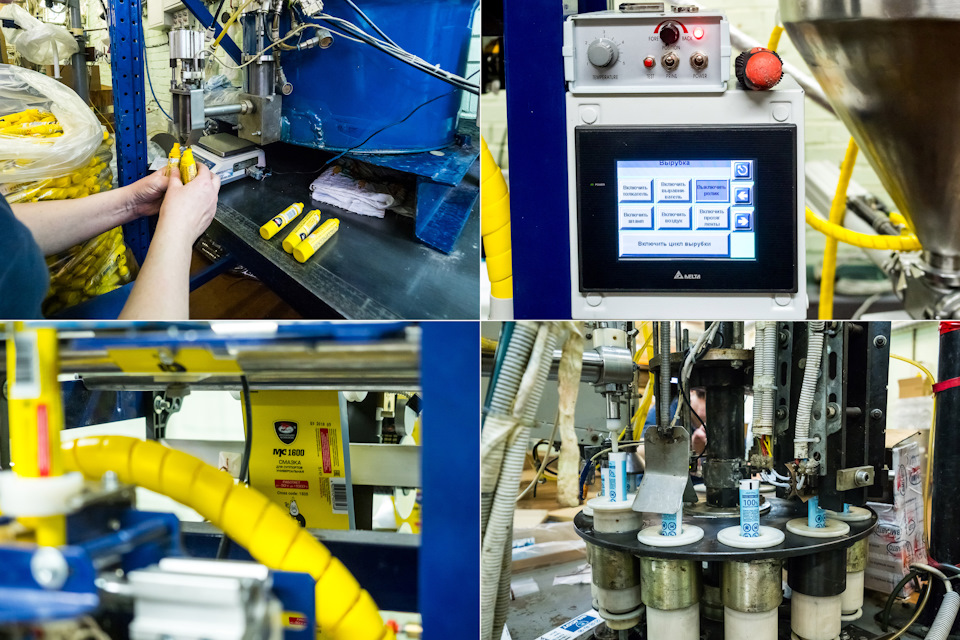

Apparatus for packing, is called the “mosquito”.

Using “mosquito” grease of the bins fills stick packages and other types of packaging transparent bags, tubes and cartridges.

It would seem a simple operation, but challenging mechanics. The process is broken into a series of simple operations. The company is proud to state that all packaging equipment — its own development. Why not buy ready-made equipment?

The fact that packaging machines for viscous products on the market, designed first on monoproduct, secondly, for higher performance, making them unprofitable for small businesses with frequent updating of the product line.

In addition, the use of equipment of its own design allows you to pack on the equipment of different products with minimal changeover time.

Currently, the company uses the fourth generation of cars, is preparing to launch a machine of the fifth generation.

All these machines are developed in the automation Department.

Production automation

The automation unit has three groups of experts. The first computer scientists. They ensure that all the equipment worked independently, and provide accurate dosing of the components.

Full sizeCEO and founder Vasiliy Nikolayevich Kuzmin, is proud that all of the hardware, such as the new reactor in the company do on their own. Some of the components, of course, buy on the side. Italian pumps are made in China, as Russian controllers.

Full sizeCEO and founder Vasiliy Nikolayevich Kuzmin, is proud that all of the hardware, such as the new reactor in the company do on their own. Some of the components, of course, buy on the side. Italian pumps are made in China, as Russian controllers.

The second group of engineers, draftsmen, designers, creating new equipment available on the market and manufactured independently of the components. Design of mechanisms is carried out in 3D design Solid Works.

The third group deals with equipment maintenance — prevention, cleaning, repair and so on.

Full sizeExamples of finished products — industrial and custom grease, penetrating lubricant, lapping valves etc.

Full sizeExamples of finished products — industrial and custom grease, penetrating lubricant, lapping valves etc.

So are lubricants in Russia! What do you think about this? In the comments you can leave your opinion and ask questions on the production.

Read also my other production reports:

— How do brake pads

— How do the tires

— How do Mitsubishi

— How do the Nissan cars

— How coal is mined

IlyaSimf

Alas, a photo of the bulkheads is lost, there are the bearings before and after. When I first after purchase of the wheel went through. Can a picture tube of lubricant, if it helps.

I don't to convince someone wanted. I do not sell grease to a foaming at the mouth to praise them. Could not pass by that delusional opinion, because if they say white is "black" is dumb. And as for any product — it is better to try and make up their minds

This ' ere in all subjects looking for the catch, and Chait everything, but praises Litol)

Multic72

Based lubricant Litol! GREASE! But nothing is said about grease for the guides in the calipers, they are often generally based on silicone plus additive. They don't all make based on licola.

"And you're not lying by any chance?;)" I wrote my opinion about the real use of the greases of this firm. And what is your statement? It looks like you are here "pobalabolit" Amateur...

So, Troll much he...

hodovik-razval

I was under the impression about your lies because you do not concretize about what dust is about.

You say "boots slide" — a stupid thing to say (the professionals do not say). Because there is a dust boot of the caliper piston, and has a boot rail caliper. They are different things and they need to be lubricated with different lubricants.

This implies that you either actually do never grease or lubricate all grease. Hence shoals.

And then you made a grease dunno (which can lubricate everything))) that it will not hurt anything (but is unlikely to have useful properties), and you are happy.

Uncle trust me nobody cares about your impression, not used, do not use on, someone is forcing to purchase and use?IAW Litol everywhere and you will have happiness.

)))

I have a CV joint at the limit, the angle is around 25-30 on the cardan shaft at the transfer case, so all our Nan-Anan burned to zero through 3 thousand and the CV joint fell apart on the ring road corny from simple overheating! blue from overheating, the clip snapped in two)

Now I have ezd on the blueprint from liquimoly 700r bought at the old prices and 8тык not obovalis))

The Germans bought the vases and was going to Mercedes to produce.

Set up the line, launched, look – out “Lada” turned out.

Brought a new line from Germany, has launched – the output of “Lada”

Fired staff, brought the Germans launched a line – the output of “Zhiguli”.

But this time next to the plant are the former Director and former chief engineer.

And chief engineer Director says

– I told you that the place is cursed, and you're all – hands of assholes, hands

of assholes!

Everything is beautiful like in a fairy tale))) Sorry that CV joints do not know)

As in the joke about the Assembly of Mercedes on the vase.

👍

If the school had a lesson on the distortion of meaning and the substitution of concepts, you would be "excellent" for this item )

We talked about the initial period of production of lubricants

Today the level of automation, equipment, quality control and development in the times higher. We are proud of it

Vmpavto

And the bulkheads were not, and lubricants, and car :)))) nothing happened. And in General, the potato grows on trees.

Grease MC-1000 is also available in jars and in tubes and bags of several weights.

Your words here were: what is your lubrication was made on the basis of different Nicolov and it is possible that some of them were bad (such manufacturer is the recognition of the fact that doing unstable stuff))).

I described a real case for a specific package (in the Bank). People probably used by another party (in tube).

Vmpavto

You useless to explain technology metalloplastikovaya how to pour out of a sieve. You can even direct links and not open to arguments from the manufacturer for you not the case.

Who used the grease that will confirm its effectiveness.

Look on the Internet about metalloplastikovye. You're such a Council give us about the counterfeit goods.

Why in your own words to say a few words. The wonder it deserves so we knew about it.

Never trust a man who will prove to me that I received personally, experience not true.

I described a specific case with specific grease. It was to me personally. there were other observations, less bright, so I don't remember. However, the experience develops the attitude of a particular product. I expressed — their attitude.

You know their schools (if the subject).

About skill no doubt: I myself am an engineer graduated from a good automotive COLLEGE in 1992. I don't think there any engineer, but which you refer, more competent in car repair.

Negative reviews are most often published than positive.

We try to comment on them if we meet in the network. But the correct summary is necessary complete picture of the condition of the site prior to the application of technology of repair and operating conditions.

Obsluzhivanie and repair of the car with his hands is not easy and has some pitfalls. In the professional services, the percentage of negative reviews is minimal.

If the act of testing and the opinion of the chief engineer of the bureaucracy for you, then thank you. Even if you pile technical specifications will provide you this will not be enough

If you heard him, and tried to prove his innocence by any means, the dialogue would have ended many posts ago.

Vmpavto

This is where gossip, rumors and negative reputation of the company.

You are even given on a platter to mention a test to read not. Laziness. And continue to bend the line, "I know better". To build their judgments on speculation and assumptions is a dead end. Sadly, if that is your motto in life.

We can produce everything the client wishes. But if the supply of prescribed specifications and brand of the grease MC-1000, Blue, MC-1600 or the other, come they. Variations of lubricants too. This is done to meet the specific needs of the plant. They come with the obligatory words in the documents. In such cases, the acts, admissions and statements of the application will have on its special brand of lubricants.

In the examples use the same grease that is Packed in cartridges and tubes for retail sale.

I can distribute you links, negative reviews about your lubricants. You all read?

In a technical dispute must be real (technical) arguments, not bureaucratic links to the documents.

I asked you specific questions. which can easily reveal all the contradictions are "universal" lubricants and links on papers sent. It is not good.

Vmpavto

Again speculation and stereotypes.

You have already explained that the physics need to know. The particle size is of importance to you?

You can read or taken out of context only what you need?

Since 2012, we synthesize the basic grease of their capacity.

At the same time I want to end the conversation with you personally. Because it is useless.

Fuuck, plums counted))

Well you did not specify the size of the particles. As I turn on physics when there is little baseline data? So far you look more like metaphysics.

Again speculation and stereotypes.

You have already explained that the physics need to know. The particle size is of importance to you?

You can read or taken out of context only what you need?

Since 2012, we synthesize the basic grease of their capacity.

At the same time I want to end the conversation with you personally. Because it is useless.

Vmpavto

1) in the 90s it was all wonderful. But all imported, and a fortiori of divine origin. No, in the 90s we produced analogues Wynn's

2)Yes, I'm saying that was laying in Litol and CV joints, and grease. Did I write somewhere that I did not know Sassa mode? With respect to known lubricants, the manufacturer of the USSR. Someone could get certainly used and their joint-4.

3) similarly in the market today a dozen of polyurea greases. Why so few people are willing to buy them? I guess because of the price.

4) under the "lithol" we, for simplicity, mean just lithium grease in the base. Black color give solid lubrication anti-friction additives. It is unlikely that sedentary loaded point contact, typical ball joint boot, oil film may have the required strength without compromising other properties. Therefore, as our lubricant recommended for ball CV joints, and similar, contain solid anti-friction additives. And additionally metalloprotease complex, significantly limiting the rate of wear.

5) One of the main criteria of efficiency of lubrication (SKF) is the factor of speed. It represents the product of the average diameter of the bearings and skorosti of rotation. For BelAZ, and Zhiguli factors speed close. And that means "to liquefy" the grease is in these bearings is approximately equal. When we talk about "super loads", we mean either a fully loaded BelAZ body, or the car caught one of the wheels in a pit on medium speed.

If you have the desire to continue the dialogue, I can send a list of questions for the scientific and technical Department and engineers.

Here are your "solid additive" (nature of the substances which you hesitate to call it that), they do harm to bearings. Imagine the process, when the contact ball (roller) with the surface of the treadmill wedged "solid particle your supplements". Will happen either the vibration of the ball (noise), increase the rolling resistance, heating. Solid particle will adhere on the surface friction and this can cause pitting.

I think that the grease that razigrani in my case, was just made of suck Licola (or what you are doing there). It's a case of "floating" quality to your production.

Sorry, if so. But I think that for example at Toyota in St. Petersburg, is practically impossible.

AvisR

Yes and no. The mentality of the worker effect is very strong. Go and find Vasin defective seam under body sealant, especially if the output from the welding is a friend of Peter, which yesterday Vasya was crushed in the evening a bottle... And even worse, the same mentality and the leadership is pushing a very heavy mount - shelf-life over a pair of pallet germet - it doesn't matter, he still rules, though you can smear at least. And it turns out you can't. That is, "they" — but I had some dances with a tambourine to run, something like "warm up application", "handle special primer ### surface"... (this is from the real St. Petersburg auto industry). But saved.

I think that in the modern workplace the probability of poor weld on the body are virtually eliminated.

Kaydanov

Normal test on the rails is worth it (in Germany), about 200 000 euros

this is not an argument in favor of not tested lubricant thrown on the market.

Of course, this is not an argument. Could a standard Vaga to study, there are requirements to lubricants for guides.

wazzup84

Good move VMP, but no...

Confidence in this office no... they have just**Bali all and Sundry.

No. It was about 1000 MS in a round plastic jar (I even picture provided). Read carefully. Hearken to the essence of the theme: but the fact that the representative of the plant admitted that at different times, in different banks might apply different bases. So, I got an outright leftist.

And you have my permission to use these lubricants. Hawa this lubrication, at least for a bread spread. I do not care. I generally type is when people are ruining their cars bad lubrication (every week I change at a few dead bearings and CV joints

It was about МС1000. Please the extreme right. I applied for a car in that photo (aka BJ). Actually, your theory of cheating myself angry people from the Internet is crashing... Give back in the form of "but where is the same Bank that I was talking about" or "you just carry these tubes and clog all lithol" is the equivalent of liquid obserw. However, in other branches you have already merged...

hodovik-razval

So maybe the bulkhead was not any?

You say "the tube" and I'm talking about "the Bank" (see photo).

Already you get the memo not about that. And how much more you could have tell a lie?

Your move ?

hodovik-razval

So maybe the bulkhead was not any?

You say "the tube" and I'm talking about "the Bank" (see photo).

Already you get the memo not about that. And how much more you could have tell a lie?

Amid the cars that in BJ

artemspec

No, not in this case — there is a global "conspiracy" that involves all, both producers and lawmakers, and environmentalists.

The car is the product that runs their 3-5 years and then be disposed of or sale of a third world country...

Can result in this case is an example of the Japanese (specifically Toyota) . After 3 years they have citizens taking the car — if the owner agrees! Him new! And this is on the line, maybe with parakram, and again the machine on sale in other countries.

Had the misfortune to lubricate the caliper pins with the grease of the firm (the white one, on the basis of titanium compounds like). Through the season barely dug out of their seats.

Since then, only PFG-110.

I would say that the photo with peremeshivanie installations is quite typical mixing device, which in the production of polymer composite materials are used exactly 10 years, and in the mineral water even longer. They are now even in retail, are sold as attachments for drills.

Another "megaparty". Guys, you'll need to understand once and for all on the nose: Vmpavto is a lot a lot of show-off, and absolutely srednika parameters lubricants + a lot of noise and advertising.

A good product needs no advertising. This life has taught me. If the product is in demand, it really brings profits and benefits to customers — speaking unnecessary, it's respect for themselves and their image. In Russia invent the wheel for two reasons: you want to make money want to make money on a short-term basis. Konstantin thanks, thanks it is I know not worth taking.

artemspec

You are quite right. Different types of mechanisms put different grease in accordance with the design and the load.

Sorry, Masty grease is in the wheel bearings. In the case of the UAZ back in the kingpin. Back to the question above why 10 types for the same bridges. Big trucks the Toyota does, so that the lubricant that goes to the bearings kruzak safely suitable for small fry.

AvisR

Not in the PMF car work? )))

No, not in the PMF. Although the same three letters in the name. :) Although if it pays well I'd done.

it seems to have all the norms and standards for the repair — priori stupid idea :)))

it is understandable :)))

as the proverb

fools law does not apply

if you write do not read

if you read something is not understood

if the concept is wrong :)))

for SIM otklanivayus

I'm sorry if something wrong :)

njdj

in this case, you skilfully beat the time of providing the materials to you

and consciously knowing that overdose will cause overflow

went for it

and then just put normal

two tariffs in the pocket

because the woman you have served

because I'm stupid :)))

with me would you do such a cheap trick would not pass

Yes, my material — but the norm in the bearings I would have control over your soul standing

and everything would be tip top :)

already passed

know

Nonsense not say. I haven't told you is that he took with the ladies the money for re-repair;)

Women I have the smartest clients (because it is not clever) and you get a quality service.

And with guys like you all the time trying to impose upon me some of his stupid plans. From this, and then get on the coin. Because I fundamentally advise against stupid once. Then rebuild the work plan so that nerd got what he wants, and then give him what is necessary))).

Your stupid idea about the quantity of grease in the wheel hub Lada is complete nonsense (there can be pedologice, but impossible to shift)).

I in factories 5 and a half years, and has worked personally different have seen. As good examples, as well as fierce scoop. Besides, you know what get hurt everywhere, not only us. Abroad — too often there are serious accidents. Obviously, there is some irreducible quantity that characterizes the number of accidents that occur, regardless of the readiness of plant personnel and the current level of spending on safety. The cause of her fatigue and loss of workers ' attention (they are inevitable), a conscious violation of TB, saving protection (save for them always have), deterioration of assets.

From my practice particularly egregious three cases: in machining shop fitter climbed into the machine is not putting the sign "do not turn, working people", the operator turned it on, but have seen raised covers, the Adjuster arm torn off; in a foundry, the foundry poured aluminum scoop his boots, having projigi tissue to the bone; well, ten minutes after shift warehouse worker, a young man, wearing headphones, came with the territory and a hundred meters from the entrance was hit by a train. Buried in a closed coffin.

AvisR

Yes and no. The mentality of the worker effect is very strong. Go and find Vasin defective seam under body sealant, especially if the output from the welding is a friend of Peter, which yesterday Vasya was crushed in the evening a bottle... And even worse, the same mentality and the leadership is pushing a very heavy mount - shelf-life over a pair of pallet germet - it doesn't matter, he still rules, though you can smear at least. And it turns out you can't. That is, "they" — but I had some dances with a tambourine to run, something like "warm up application", "handle special primer ### surface"... (this is from the real St. Petersburg auto industry). But saved.

The problem Alex and Bob classic. And like any classical problem, it has installed solutions years from the ' 70s or something. For example, through the increased responsibility of the Vasi/Petit, when a neighbor handed over to the authorities a fool, come to work with a hangover. And a fool will not hurt yourself, and better quality products, and neighbor award. Through the creation of a conflict of interest when Pete will be a tangible prize for each jamb Vasey. Checked already, it will work effectively regardless of the mentality of the workers, their family ties, etc. can be Solved, in General, would need.

pater-NIkita

No, he's not SUPROTEC PR. SUPROTEC him to sue for allegedly false disclosure. And, who knows, honest or not is unknown to me. While the eyes have not learned to identify. However, the PMF of Cars is now a lot of good reports and this is alarming. With SUPROTEC there was a similar theme, but it was the usual "divorce". For me there is no doubt that if some blogger wrote about SUPROTEC, the post paid for. :( How would Vmpavto such a situation was not :(

By the way, Tom, is in the CMC office, which makes oils and additives — called Cooper. I somehow in the transfer of Sergei Aslanyan watched an interview with their Director. They do everything based on copper, creates a protective layer, blah blah blah. It would be interesting to read about them. If you do report them, I would gladly esteemed — indeed, so eager to believe in miracles :)))

Have a negative experience use of products of Cooper. See my in-flight magazine.

Believe it or not, fucking with my brother.

There is a company of Henkel and that's it. All the rest to her as to Shanghai with cancer.

How is it useless ? And then what to do with them ? :)

Countersink angles are corrected, priter... like go :)

kemoman

They have excellent paste for lapping valves. Now I got grease on the caliper guides, but by reading the comments, dumb now )) Is that bad and sour napravleni ?

it is useless to grind in the valve, when the heat of the engine ground locations razletayutsya

They so enjoy. Interested about RCS.

Moreover, the DNI now with the prices is not going smoothly and the customers all the time asking for cheaper.

They have excellent paste for lapping valves. Now I got grease on the caliper guides, but by reading the comments, dumb now )) Is that bad and sour napravleni ?

hodovik-razval

It's all nonsense. Oil scraper rings have a complex spatial structure. When this entire structure filled with rigid high-temperature deposits is essentially similar to reinforced concrete, which is virtually impossible to have a clear no damage (and even more in a contactless manner).

The second joint of the liquid decarbonize: if it really works, it first frees its path (around the ring) and will drain in the pan, not having anything to react.

By the way, Yes, I do not understand and do not understand how the rings not holding compression can retain the chemical compounds to decarbonize! Campaign engine that the eyeballs need to fill!

To assess the pressure of the wheel in the contact patch, don't need to know what is the size of the contact patch. Wheel pressure on the ground is almost equal to the air pressure inside the tire.

And there we are talking about the axle load, which is also not depends on the area of the contact patch.

leave fantasy to those who is not, what is the area of the contact patch and what it depends on is all for those who use the calculations of "peer review" type, "probably somewhere in the 15 times higher"

Well you do not understand simple things?

One thing specific pressure (it is the truck four times higher). Another thing is the axle load (it is also the truck several times above).

the principles are described in the literature, but man. he doesn't understand. the increase in weight load on the wheel 4 times (they invented!) kompensiruet an increase in the total area of contact of the wheels with the surface and pushes tihoreckuyu about the excess of "vertical load" the truck in alignment with the cars — they do not understand for what

such need cars to give to the garden products were taken. and — with one wheel

You showed banks with black content. And that it is only you know for certain.

No real physical principles of real decarbonize you have not voiced. One faith in a miracle. Well, as usual.

And about the truck I have clearly painted www.drive2.ru/b/471005218767634554/

I understand that it breaks the brain is not the thinking people without logic, but it's all true.

you did something come up for me and sa m trying to argue

I just showed the result of soaking, not more

however. after the nonsense that you wrote about suffering from road truck, what you write here seems more than childish prattle

You did not understand what are the differences between high-temperature and low-temperature deposits?

Why do you think that the black from the engine there are remnants of high temperature deposits, which are here all the time is it?

what does this have to work one specialist and one and the same instrument?

organize all really, the question in the nuances of...

here is an example of how beautiful was the global kerosene after soaking in the motor for a day: www.gt-four.ru/phpBB3/dow...oad/file.php?id=22922&t=1

Compression is measured in very different ways: someone violates measurement technology, one that the compression gauge is lying (almost all minders the compression gauge starts to bark after a few months after purchase)).

About the oil consumption I only know the owners of the car, and they may bark for different reasons.

If you soak the pistons in the basin with chemistry, and that people says that coked the rings so still have hope. And the real cylinder of the engine is generally impossible to arrange the rings soaking in any liquid.

reducing oil consumption is difficult to notice?

or climbing compression 6 to 14 ATI ?

the chemo eats everything

for example, trying to wash the motor with kerosene with the winter additives led to corrosion of all the cuffs and leakage thereof, Bo that additive even road markings destroys

Of course the stories "work". Especially they "work" where it is difficult to notice a specific result. Only "work" stories not with the hardware, and with people (with illogical human brain, which is inclined to believe tales).

Picture dirty oil doesn't open, but this is not necessary (I'm not stupid enough to believe in the miracle image of dirty oil)). Flushing oil is usually used for flushing low-temperature deposits or varnishes that can actually dissolve and flush small amounts. But the theme of "decarbonize" is all about other deposits — it is about high temperature deposits that chemistry is not clean.

the criterion of truth is simple "theories" is to practice, and it breaks your theory at all ;)

your doubt is your problem

I'm not pushing authority and implying. what are your stories about uneducated gullible people who believe in the efficacy of decarbonize is nothing more than your imagination

well, if you were aware of what the GDSN. with doubt issues would have :)

everything works for many people, work on yourself and you're gonna get

for a small illustration here's a picture — flushing oil from the jar and after 1 hour at idle:

matvey1.users.photofile.r...8071/xlarge/212875951.jpg

Well, I describe the theory of your mistakes. Why don't you contest it, do not bring convincing arguments that would destroy my doubts at times?

Instead, you are trying to push some sort of mythical his authority (which gives me serious doubts), bypassing all my real questions.

living in the light of already pretty, have education, experience in scientific experimental work with the highest quality requirements, measurements and procedure of the experiment and rinsing and raskoldoval do need a lot of years, began when many people were just afraid and walked the myths of sellers that need to be rinsed when changing from one oil type to another, and not for washes deposits out of the motor

everything works with the right reasonable approach without skimping on the time and thoroughness of execution of works

if you specifically can't do something practically and/or theoretically, the problem specifically in your methods of work and/or thinking, nothing more.

No. I describe you the real thing that everyone can see and touch (coked oil ring)

And you describe what is really non-existent, a fantastic process ("raskosov").

It's all nonsense. Oil scraper rings have a complex spatial structure. When this entire structure filled with rigid high-temperature deposits is essentially similar to reinforced concrete, which is virtually impossible to have a clear no damage (and even more in a contactless manner).

The second joint of the liquid decarbonize: if it really works, it first frees its path (around the ring) and will drain in the pan, not having anything to react.

happened. mechanical impact when rusconsult — periodic movement of the pistons up and down + motor work. especially on the flush oil, repeat treatments so a treatment physico-chemical effects

And you used a rust Converter? Many times I have used it.

If you stupidly wet rust Converter, the result will be practically zero. Because the Converter will react only with the outer layers of rust and all.Because he's stupid doesn't penetrate into the deeper layers of rust.

A rust Converter like that really only works with a specific contact mechanical destruction of the layer of rust.

Racconsole impossible without mechanical impact of high temperature deposits on piston oil rings (by the way, and this is also impossible)).

well. if horizons is committed to the point...

let's try to simplify: there are rust converters, which react with metal oxides, but not interact with them

if it did not repent, it is likely a hopeless case

it? there are more than three and the motors not dead, There are turboserve

when runs of 500 KCM has varied only consumables. on the main old man, even so the choke was not cleaned, and he rides with me 99

here he is in 2005 and began to eat the butter as insane as washing and decarbonize this issue was removed so that today it is quite normal travels, and the oil flow rate is not alarming

no need to bring stupidity is not our people composed

chemistry eats what he can. it is obvious, like the fact that it gradually merges into the pan

Cox it softens, which allows the entrainment with the oil, flushing oil washes off, of course, better. why use it

"Their engines" — as it means that we are talking about your personal machines. How many have you had? Three or less? Why do you have all the cars were with dead motors? From the fact that you're so smart? (there is a proverb: "if you're so smart, why are you so poor?"))

No need to write history and confuse. Just explain the mechanism of how some sort of substance can identify the cylinder coke and does not merge in the pallet, and stay specifically in the area of coke and make coke did not (we are talking about high-temperature deposits that physically it is impossible to pick open).

uncle, the results of my research on physics published under the heading GDSN, if you're saying something, and flushes and Rakovka do on my engines since 2005, the experience is purely positive, well, if in numbers, the raising of compression with a 6 to 9 to 14 Athy in all the pots of antiquity 3sfe — a common occurrence, the last time the Batin 1зз tortured for several days, so this proglotila much of the oil has ceased, although the famous lover, Bo motor 1-th class of ' 98, who in the subject — knows

so no need of tales, any private experience speaks primarily about himself, if you can't do something doesn't mean it won't for another

by the way, TV don't have :)

Ren are watching? (about quantum leaps of nanomateria))). Well, it's the same crap for the uneducated gullible people.

hodovik-razval

Any person who has ever tried THEIR HANDS clean of high temperature deposits on piston oil rings, never believe in the efficacy of "decarbonize".

if he can't grasp that in addition to purely mechanical methods of influence can be other

this is from the limited horizons

hodovik-razval

Is marketing this type of product — "pseudoscientific".

People willingly eats everything that looks like invazia.

The most cynical marketers have long prohavali and it is actively used in the business.

I've been watching it in different spheres of consumption.

In the automotive aftermarket this is a very popular destination.

Here's an example I remember:

1) the "Helicopter" ball for Lada, which do, what is the Voronezh defense company (under CONVERSION) during the second half of the 90s. It really was a very reliable ball joints and people remember them well. Then came the forgery, and all poher.

2) St. Petersburg dampers Plaza. It was very cool — people just Ssali with delight. There didn't seem defensive theme, and the theme of technology from MOTORSPORT (also very cool))). The shock absorbers were very unusual, of course (single-chamber, gas-filled), but in practice — a rare shit. Years passed and the people became disillusioned.

3) Samara SS-20. The type of AVIATION technologies. Also very creative KB allegedly did things advanced. Norodom still dig it, but the negative reviews have to where probably more than half.

5) Hado from Ukraine. There are also such INNOVATIVE technology, a lot of magic and miracle. In short, people are not stupid, but making progress na an empty space (actually, a lot of dough invested in advertising, and in fact it is a simple "blender").

6) fulcrum (made of polyurethane, replacing the entire vibration-proof rubber in vehicle). The newest material that has WONDERFUL properties. This is not outdated rubber, it's in a million times cooler))). Perfect for our bad roads. People hawala this business with enthusiasm. But as with any miracle, it eventually showed his true stupidity.

7) the Firmware of the brain varied. "DIGITAL" people divorce on the headstock (this is perhaps now the most recent type of pseudo-scientific marketing). He has not gone on the decline — people are willing to hawala)).

8) And how many diverse and wonderful additives in fuels and in oil — they do not count.

----------------------------------------

But we must pay tribute to the wisdom of the people: people hawala miracle of ten years and then slowly begins to realize his mistakes.

I agree with everything except firmware. Revo confirmation.

And Hado have good products, but of course miracles is silly to wait

Tupi, like a sheep, like smart. of course nothing, the producers for each HP just beat, vybe.t 5L. C and don't know how to show off., Good luck in your tochylove with the engine 1,6 1,4 and other trash.

5-12% is the placebo effect.

At least you will learn the scientific method of checking the fuel consumption, methods of measurement of power, etc. Then you will understand that 5-12% in these measurements is nothing.

And then, improving some quality of the car, you any degrade others. Who said that you have chosen the list of improvements maximum reasonable for everyone?

hodovik-razval

Is marketing this type of product — "pseudoscientific".

People willingly eats everything that looks like invazia.

The most cynical marketers have long prohavali and it is actively used in the business.

I've been watching it in different spheres of consumption.

In the automotive aftermarket this is a very popular destination.

Here's an example I remember:

1) the "Helicopter" ball for Lada, which do, what is the Voronezh defense company (under CONVERSION) during the second half of the 90s. It really was a very reliable ball joints and people remember them well. Then came the forgery, and all poher.

2) St. Petersburg dampers Plaza. It was very cool — people just Ssali with delight. There didn't seem defensive theme, and the theme of technology from MOTORSPORT (also very cool))). The shock absorbers were very unusual, of course (single-chamber, gas-filled), but in practice — a rare shit. Years passed and the people became disillusioned.

3) Samara SS-20. The type of AVIATION technologies. Also very creative KB allegedly did things advanced. Norodom still dig it, but the negative reviews have to where probably more than half.

5) Hado from Ukraine. There are also such INNOVATIVE technology, a lot of magic and miracle. In short, people are not stupid, but making progress na an empty space (actually, a lot of dough invested in advertising, and in fact it is a simple "blender").

6) fulcrum (made of polyurethane, replacing the entire vibration-proof rubber in vehicle). The newest material that has WONDERFUL properties. This is not outdated rubber, it's in a million times cooler))). Perfect for our bad roads. People hawala this business with enthusiasm. But as with any miracle, it eventually showed his true stupidity.

7) the Firmware of the brain varied. "DIGITAL" people divorce on the headstock (this is perhaps now the most recent type of pseudo-scientific marketing). He has not gone on the decline — people are willing to hawala)).

8) And how many diverse and wonderful additives in fuels and in oil — they do not count.

----------------------------------------

But we must pay tribute to the wisdom of the people: people hawala miracle of ten years and then slowly begins to realize his mistakes.

all true, but the paragraph 7 nonsense. Really helps, of course within reasonable limits. No 50% increase )))) 5-12% actually, removing the environment is not needed in Russia, very expensive catalysts and other crap the usr! Personal experience. Car goes over 200km/h limiter removed, driving the pedal to the floor does not rise, consumption fell, too, not fiction on real 800gr-1 liter. And acceleration and the transmission is quite different. So the setup really works. Especially if it's not about the miracle of the flash drive or something somewhere to insert and trample )))

volgovskoe bushings and rubber fully, I didn't know what to stick, some worse than others, so I had to take a risk, like the third year came as and while are all fine, but the springs probably makes no sense to push polyurethane

I don't want to put it, and the price is more than 5 Grand for the kit just the bushings on the GAS 24.

Devil9666

In less than polyurethane and the pros?

Devil9666 minus one, not kept in a cage, plus artisanal production with unpredictable quality, there is as lucky. I have a rear beam stand and then because I did not found anything except a really bad Masumi and thebest in the sale, and therefore put a polyurethane. Like while all is normal. the original bushes no change with the beam. but in the front arms polyurethane afraid to put.

Yes, heard creaks and gives fatigue to the metal because of the violent type of rubber and the suspension transmits bumps to the body.

Nothing good I do not know about the polyurethane. But I know that no one global automaker uses it instead of rubber. For me it's a very powerful argument.

hodovik-razval

Is marketing this type of product — "pseudoscientific".

People willingly eats everything that looks like invazia.

The most cynical marketers have long prohavali and it is actively used in the business.

I've been watching it in different spheres of consumption.

In the automotive aftermarket this is a very popular destination.

Here's an example I remember:

1) the "Helicopter" ball for Lada, which do, what is the Voronezh defense company (under CONVERSION) during the second half of the 90s. It really was a very reliable ball joints and people remember them well. Then came the forgery, and all poher.

2) St. Petersburg dampers Plaza. It was very cool — people just Ssali with delight. There didn't seem defensive theme, and the theme of technology from MOTORSPORT (also very cool))). The shock absorbers were very unusual, of course (single-chamber, gas-filled), but in practice — a rare shit. Years passed and the people became disillusioned.

3) Samara SS-20. The type of AVIATION technologies. Also very creative KB allegedly did things advanced. Norodom still dig it, but the negative reviews have to where probably more than half.

5) Hado from Ukraine. There are also such INNOVATIVE technology, a lot of magic and miracle. In short, people are not stupid, but making progress na an empty space (actually, a lot of dough invested in advertising, and in fact it is a simple "blender").

6) fulcrum (made of polyurethane, replacing the entire vibration-proof rubber in vehicle). The newest material that has WONDERFUL properties. This is not outdated rubber, it's in a million times cooler))). Perfect for our bad roads. People hawala this business with enthusiasm. But as with any miracle, it eventually showed his true stupidity.

7) the Firmware of the brain varied. "DIGITAL" people divorce on the headstock (this is perhaps now the most recent type of pseudo-scientific marketing). He has not gone on the decline — people are willing to hawala)).

8) And how many diverse and wonderful additives in fuels and in oil — they do not count.

----------------------------------------

But we must pay tribute to the wisdom of the people: people hawala miracle of ten years and then slowly begins to realize his mistakes.

In less than polyurethane and the pros?

Life at them such, Brody, dirt, water on the windshield. Severe conditions of existence. Litol just immediately evaporates.

Yes I am not on my bearings judge, I'm the wrong bearings change on a few pieces a week. Why do you have the bearings 1000 MS if there is a quality Litol, which is much better for bearings and is cheaper (100 MS is made on the basis Licola)? Why do you have water in the bearings?

Exactly evil. You really ran into a bad quality, or casually on the counterfeit? I have in the front bearings Packed мс1000, like walking and water holds.

When you write the word "nowhere" into two words, it is not clear what you want to say (one thing is clear — that you spewed some evil))).

Is marketing this type of product — "pseudoscientific".

People willingly eats everything that looks like invazia.

The most cynical marketers have long prohavali and it is actively used in the business.

I've been watching it in different spheres of consumption.

In the automotive aftermarket this is a very popular destination.

Here's an example I remember:

1) the "Helicopter" ball for Lada, which do, what is the Voronezh defense company (under CONVERSION) during the second half of the 90s. It really was a very reliable ball joints and people remember them well. Then came the forgery, and all poher.

2) St. Petersburg dampers Plaza. It was very cool — people just Ssali with delight. There didn't seem defensive theme, and the theme of technology from MOTORSPORT (also very cool))). The shock absorbers were very unusual, of course (single-chamber, gas-filled), but in practice — a rare shit. Years passed and the people became disillusioned.

3) Samara SS-20. The type of AVIATION technologies. Also very creative KB allegedly did things advanced. Norodom still dig it, but the negative reviews have to where probably more than half.

5) Hado from Ukraine. There are also such INNOVATIVE technology, a lot of magic and miracle. In short, people are not stupid, but making progress na an empty space (actually, a lot of dough invested in advertising, and in fact it is a simple "blender").

6) fulcrum (made of polyurethane, replacing the entire vibration-proof rubber in vehicle). The newest material that has WONDERFUL properties. This is not outdated rubber, it's in a million times cooler))). Perfect for our bad roads. People hawala this business with enthusiasm. But as with any miracle, it eventually showed his true stupidity.

7) the Firmware of the brain varied. "DIGITAL" people divorce on the headstock (this is perhaps now the most recent type of pseudo-scientific marketing). He has not gone on the decline — people are willing to hawala)).

8) And how many diverse and wonderful additives in fuels and in oil — they do not count.

----------------------------------------

But we must pay tribute to the wisdom of the people: people hawala miracle of ten years and then slowly begins to realize his mistakes.

hodovik-razval

Representative PMF then admitted that not all of the stuff they cook. They did use foreign bases (lithol for example), and theirs managers are not always normal base on the buy side.

You in yourself? Do not misinterpret the words.

Well, this is nothing new, and bad in the "repacking" is also nothing. The bad thing is that not a quality you take, and tell that quality. A General who used their lubricants that will take longer. I'm not talking about those who all their grease smeared, and the car does not go. So mileage 7-8 km per year . With such mileage you even a Chinese throwing star, with a smell of menthol to smear all.

Representative PMF then admitted that not all of the stuff they cook. They did use foreign bases (lithol for example), and theirs managers are not always normal base on the buy side.

The PMF for the guide fingers of the caliper, from personal experience, bad lubrication is in the first place.

And secondly, not even reading the record know what is written there — all super modern and the chemicals and equipment and technical process in General.

Well, from here a question: any other lubricant where done ? In the kitchen in a pot improvised brewed ? Or in garages in barrels with a stick in the way ?

All of them, according to the description, modern and good but somehow bad...

Devil9666

Real grease on the stove to heat up almost to a liquid state?

And temperature range of use licola from -40 to +130

So I say that brake fluid is necessary to lubricate the piston during Assembly (it always smeared). There is no more grease and do not need nafig.

it was about the lubrication of the caliper piston! Given rolling lubrication for this and ramitana. And in contact with brake fluids harm them and the brake system is not pricenet. That's all. And the piston needs skazyvaetsya with two sides, one with brake fluid and the other with special grease. That is the way any caliper modern machines. The conversation over the shield.

Are utter nonsense. What's under the dust boot to lubricate? The piston is recessed in the cylinder of a millimeter and comes out with each press on the brake pedal. While it is anyone lubricated with brake fluid (which is in the cylinder). And your fuel oil will be on any simple cake somewhere in the anther and all.

And again I repeat to you: here we were talking about the Assembly of the cylinder (when the piston inserted into the cylinder it at any time has to spread, otherwise you'll turn up the cuff). It was during this conversation you got with your grease.

Why is it smear at all? On the pelvis probably inappropriately if the manufacturer says Nenad. But that and the pelvis anything to smear Nenad!

All branded cars under pilnik laid the grease to lubricate the caliper piston. But the pelvis is worthlessness. Well, you I understand too.

You first read what we're talking about in the subject.

What fool will put that there "between the dust boot and o-ring"? Why is it smear at all?

In this thread talking about how to lubricate the piston and seal ring during Assembly of the cylinder with the piston.

Fingered and not 1 time, turn the brain and think about how to spread the grease between pilnik and o-ring so they don't contaminate the brake fluid.

You do what ever rebuilt a caliper? If you spread the grease piston and O-RING (cuff) in the cylinder when inserting the piston into the cylinder, this grease on any gets in the cylinder (in a hydraulic system). But how else?

lubrication is not in contact with tormozuhoy, it is located between pilnik and cylinder. and tormozuha is inside the caliper and if germetizirujut ring let the tormozuhoy in grease or lubricant in the tormozuhoy the slide needs to be repaired and not ekspluatirovat. And lubrication brake fluid piston from the top to nothing lead as tomosugi nothing left after a week.

And what it becomes when it gets in the hydraulic system? Not really, she transformed it into a brake fluid?

And why smear the piston that is lubricated? Why is it better than to smear the piston tormozuhoy?

hodovik-razval

You are a perfect user of course)).

In General, there is no reason to lubricate anything exposed surfaces (in the first rain, the grease will be washed away).

It makes no sense to spread than either of the surface, which will then contact with brake fluid (because the grease will get dirt in the brake system). These surfaces, if necessary, smear in the Assembly of the brake fluid.

The only thing that you need to lubricate the caliper is a floating guide bracket (and not all), and for this purpose, any suitable lubricant that will not dry by itself with time or will not dissolve the anthers.

You're completely wrong and lead people into deception!

03.9902-0521.2 ATE here a number of lubrication known company for the production of brake systems and not only. This primenyaetsya grease to lubricate the brake porchenkov with the calipers. And she's not getting grassy in the brake system!

If "adhesion and water resistance" really be as strong as you think, it would not be in the car anthers (and even some seals)). The same goes for "pressed against each other the details."

Well, what about the "over not through" if you just oiled the cylinder and boot?

Any piston will be lubricated with brake fluid (he's bathed in it). In addition, under the dust cover should not be air circulation from where the liquid could absorb a lot of moisture.

Read the official Wazowski instructions for the Assembly of the calipers (on Vases applied caliper Lukas) (see the picture at the end of the message).

For every "perfect consumer" has a "key" (a"key" for you is already written in the memory spam robots)).

Well, why the water washed away? What about adhesion and water resistance of lubricants? Besides how it will wash, if it is between pressed-together parts?

When assembling the caliper, the grease helps to stick the piston into the caliper, and the surplus is still not fit through the cuff inside — the excess will simply remain outside. But to lubricate the pistons when assembling tormozuhoy think is not a good idea, as tormozuha very hygroscopic and the same pressed before the cuff over sure type of water and will lead to a wedge, at least in a cast-iron brackets.

In General the ideal consumer I is very difficult to call — I'm not buying additives, washing, don't blow the tires nitrogen, and do not overpay for the advertised brand. Buying this grease, I was guided by the fact that the previous (not specialized) in napravleno had dried up and decided to try specialized. And since I bought a tube, then why not anoint a thin layer of bottlenecks, at least on the principle of conservation of layer from direct exposure to moisture, chemicals and other chemicals.

the-fearless

Good day! Recently bought МС1600 and grease when overhauling the brakes lubricated her pistons, cuffs, parts of the pad that contact the piston and caliper and guides. But in the comments to this article I read that sending some lubricant МС1630 and МС1600 you already do not recommend this application. The best way to proceed is to leave as is, or replace the lubricant in the guide on special?

You are a perfect user of course)).

In General, there is no reason to lubricate anything exposed surfaces (in the first rain, the grease will be washed away).

It makes no sense to spread than either of the surface, which will then contact with brake fluid (because the grease will get dirt in the brake system). These surfaces, if necessary, smear in the Assembly of the brake fluid.

The only thing that you need to lubricate the caliper is a floating guide bracket (and not all), and for this purpose, any suitable lubricant that will not dry by itself with time or will not dissolve the anthers.

Vmpavto

Grease МС1600 whimsical in the guide. This lubricant is perfectly applicable experts that are guaranteed to properly prepare the surface and put the original dust caps. If there's any chance that integrity is violated, it is better to use МС1630. It is easy to use and better suited to napravlyaet.

If you are sure that thoroughly cleanse the surface and bellow sealed, the remake makes no sense. All will go to the next bulkhead

And if the other grease all do the same thing for 10 cents — the result is the same :)))

Vmpavto

You're talking about two years, as about something insignificant :) Calipers need to be serviced every time you change pads.

We reiterate that private use in the guide, we recommend MS-1630 instead of MS-1600

And the shit factory grease in all the rules on the run for a hundred and after 5 years, tested by 3 x the Koreans.

The drive is full of reviews that your grease - guides complete a hat, change to TRW and everything is OK, nothing in the clay is converted)))

I have front calipers ATE do not require lubrication guide (dry they are there). just the pistons. It is not necessary to climb each replacement pads, none of the regulations replacement pads do not. However, after 2 years from your grease under the dust boot of the piston in addition to clay with chalk pressed into the edge of the gum is nothing left. Never use at all.

Rear caliper Lucas brake pads there is enough for 3 years. Your grease many lives even close, this is confirmed by numerous reviews, I don't know how or who is changing there, I'm not a fool. 2 years ago or 3 scored there talovskoe pink grease in the guides (what kind of know-how and what what not I don't care — taenia she only caters to their cars, I got from an employee of the Directorate. In guides and on porshni her stuff) recently changed the discs and pad lubricant ideally, viscous like yesterday was smeared and drying. the truth is pink was not clean and a bit grayish...

No desire to use МС1600 no more. Why do I need this crap? not needed. use it yourself, all the friends I discourage from using...

You're talking about two years, as about something insignificant :) Calipers need to be serviced every time you change pads.

We reiterate that private use in the guide, we recommend MS-1630 instead of MS-1600

МС1600 complete with zero the caliper (complete sandblasting, new rubbers and pistons) have become after 2 years in a pathetic semblance of either stone white, or something like that is almost soft. the pistons are not rusted, well there and the moisture should not hit...

in the guide of course also to the metal wyczesany from old greases and other solvents to generally clean it turns into clear that through the year...

after that I lost all desire to use this grease...

all that concerns litoloogiline lubricants satisfactory in other sites...

Grease МС1600 whimsical in the guide. This lubricant is perfectly applicable experts that are guaranteed to properly prepare the surface and put the original dust caps. If there's any chance that integrity is violated, it is better to use МС1630. It is easy to use and better suited to napravlyaet.

If you are sure that thoroughly cleanse the surface and bellow sealed, the remake makes no sense. All will go to the next bulkhead

Vmpavto

Good day! "left the office" appeared on the market in 1996. If You follow the release of our "stuff" and "shit", you know that from 1996 to 1999 the company produced the additive in the oil, and Scrapers — the number one among the Russian funds for cleaning hands and still.

Grease MC-1000 was introduced in 1999, at a time when everyone in Russia rode litre. It was a big step forward. I'm sure you remember that at the time and in the CV joints laid Litol, grease or lubricant from a kit ( often the same Litol):). Therefore, our anti-wear grease MC-1000 is based on licola was a good alternative and then applied at all nodes.

But still the base was Litol, which was supplemented with anti-wear additives.Each party licola differed in quality that greatly affects the quality of our final product. And in 2012 after development and testing we launched our own plant for the synthesis of lubricants. So we switched to a private lithium, litio-complex, lithium-calcium base, which guarantees stable quality. Special grease for CV joints appeared in 2004.

We declare with confidence about the high quality grease MC-1000. If she was not so good, it would be supplied to the conveyors of BelAZ, where the super loaded assemblies can withstand up to 360 tons of rock and on the conveyor From-KARTEKS, where the excavators weigh up to 1000 tons and the capacity of the rock in the buckets — up to 35 cubic meters.

Such loads 2107 never dreamed of. Therefore, such reviews continue to confound and mislead other buyers.

Good day! Recently bought МС1600 and grease when overhauling the brakes lubricated her pistons, cuffs, parts of the pad that contact the piston and caliper and guides. But in the comments to this article I read that sending some lubricant МС1630 and МС1600 you already do not recommend this application. The best way to proceed is to leave as is, or replace the lubricant in the guide on special?

— 1T. on the phone, as a maximum, or the "freebie vaseline drove", a sample!..))

looked post, and was wondering — how much the author paid for advertising? well, that's really humanly interesting.

The author in his repertoire. Here is a quote from a recording by the same author about how "in Russia do car tires" www.drive2.ru/b/470263323...96793534/page=17#comments

"Here is staffed by the most experienced plant employees, able to distinguish summer tires from winter smell, and eye, and touch to recognize over 130 of possible defects." End quote.

Now, my comment to her.

"So, we have:

1. One of the most experienced employees (controller);

2. 10,000 tires per day (which day, it is not clear, but let it be 12-hour working day);

3. 130 possible defects.

This means that one controller will check:

833 bus per hour;

14 tires per minute.

Thus, for 4.3 seconds, the controller verifies the absence/presence of one or more of the 130-and possible defects.

Again. Single supervisor of the 130 possible defects and the whole 4.3 seconds (assuming 12-hour day).

In "the Guinness Book of records" the application has not yet been filed?"

Again, the author in his repertoire.

But I am skeptical about such compositions, and do not write about them. Anyway as for additives for motor oils.

what are some types of tribological there? well, to wear smaller, or restore it and keep it down worked?

and I'm still grafickou herachat, well, sometimes lithol, in General, that will fall under the arm and normally then be unscrewed and screwed, coming and going. that work made and it is good)

Try not to use that promotes the academic, that's my rule, as shown more squeals of wonder products on the popular etob channels especially is the worst shit.

There are 2 things which severely hurt the eyes.

As they do a wide range of just 2 reactors? The reactors must be cleaned after each product change, in the case of lubricants, creates a question about the economic feasibility and actual performance. And the company is in fact sharpened by a very small party if only 2 of the reactor by 2 tons. By the way 2 days if you cook a batch, then the annual volume to meet the 600 tons or 30 trucks or 200 million rubles. despite the fact that this record a small reactor for mass production and products have a lot of reactors should be ~10. But they themselves probably know, just no money. Expect that they do the intermediate and domeshivayut until the end of the already improvised their mixers for a performance.

And then 2nd moment, that severely hurts the eyes — sales Department forms a specification for the recipe. Imagine how come a Manager with a passport pds мобил1 in the lab and asked to do under the specifications. The-W in these characteristics can go a dozen different ways and components. Icp and of the spectrum because they have no. It turns out the product on the eyes and experience of the technologist laboratory. And can be even cheaper because the most.

And live, and it's leading enterprise positioning in this area.

Razocharovan in Argo — I thought it was cool.

yeah, also wanted to write about it... if everything is so cool and the staff is not great why are so blunt on consumer reviews... ?

And the joint with grease for the rails?

The whole drive is smeared, she turned to clay.

After like me this brand is closed

Two years ago, stuffed 1630 MS grease in the caliper pins, still it functions well.

Full size

Full size Full size

Full size Full size

Full size Full size

Full size Full size

Full size Full size

Full size Full size

Full size Full size

Full size Full size

Full size Full size

Full size Full size

Full size Full size

Full size