How to make brake pads

Many do not think about the importance of safety, have the brake pads. Often when we are trying to save money, and is recommended by the manufacturer of the "original" selectable aftermarket pads brands suppliers for different conveyors, or anything else easier.

Really, why pay more, especially if you drive gently? But if something happens, for example, emergency braking, ended in the bumper in front of the car, we blame you most likely will not pads and of itself. Even if the reason really in bad stocks.

However, even buying shoes with a famous brand on the label does not guarantee high and stable characteristics. The percentage of fakes in this market are very high, and by "leftist" on any popular Internet site in almost any auto parts store.

However, the fakes, we'll talk another time, and today I propose to move to the production and to see how Russia is doing the brake pads. Specifically for this I went to the city of Tver, where in the industrial area on the outskirts there is a small "drum" plant.

About the production

The history of this production began in 2011 when one of the "automotive" brands decided to open a plant in Russia for the production of brake pads for deliveries to conveyor of car factories, producing cars of foreign brands. Thus, manufacturers could increase the percentage of localization of its vehicles including the expense of pads.

The production was designed by European experts. Was carried out selection of the equipment developed by optimal formulation of frictional blends.

Full sizeProduction moves through the processing chain on the carts in the supermarket. In small production it was very convenient. It's know-how!

Full sizeProduction moves through the processing chain on the carts in the supermarket. In small production it was very convenient. It's know-how!

The crisis has made adjustments – the long-awaited orders from automakers followed, and soon the share of foreigners in the business was purchased by Russian partners. In 2014 began the history of the brand Kotl operating in the secondary market. Today, the production capacity is 500,000 sets of brake pads per year, the plant employs 58 employees. The item is 225 items pads mainly for cars.

Now go through the processing chain.

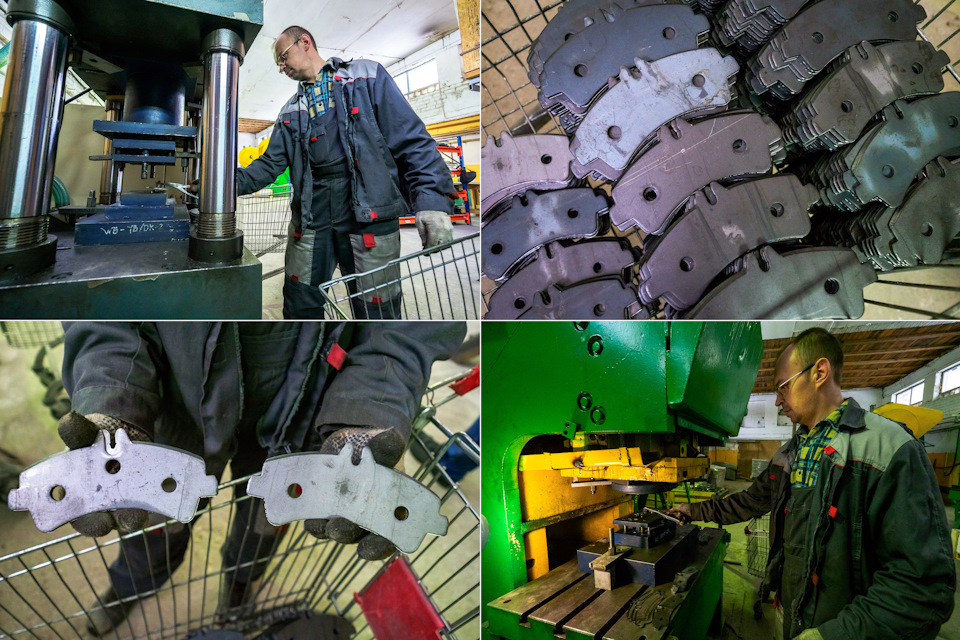

Frame pads

Brake pad consists of metal frame and preferovany to her friction parts. Accordingly, the first step is making the frame.

Full sizeProcess of cutting and machining of the frames

Full sizeProcess of cutting and machining of the frames

Most of the used barrels are doing here at the factory. With the help of cutting dies, mechanical and hydraulic presses of sheet metal production, NLMK formed the framework itself, but also the corresponding elements to it — grooves for attaching accessories, openings for electrical sensors and so on.

Full sizeFrom a sheet of metal to the billet frame

Full sizeFrom a sheet of metal to the billet frame

Part of the frames purchased on the side – basically, it is frames for domestic cars, which are widely spread, allowing you to save on stamps, which, by the way, is produced at the factory using including EDM and milling machines with CNC.

Full sizeProduction equipment and molds

Full sizeProduction equipment and molds

Part side frames made by laser cutting.

Friction compound

The main task for the manufacturer of shoes for the mass of the car is the stability coefficient of friction, regardless of the degree of heating pads.

The best indicator KT is the range of 0.35 to 0.45. Many manufacturers, including KOTL, mark your pads system SAE a two-letter index. For example, FF means that the above range of the coefficient of friction remains unchanged at the cold block and heating medium, and hot. Some companies conduct trials on their own, in this case, test the temperature ranges are held in the US in the framework of product certification.

The applied friction of the mixture belong to the class nizhneturinsky. The composition of the mixture, the ratio of the components, and, most importantly, the mode of compression – all this directly affects the characteristics, therefore, it is here and hidden an important part of the know-how of the company.

Friction compound is a mixture of friction modifiers, the structure-forming substances and fillers. Once as the matrix-forming material widely used asbestos, which has very good characteristics stability and heat sink, but later he was recognized as a carcinogen, and its use in the friction industry was discontinued.

Asbestos today is to create a matrix used various synthetic fibers – aramid, polyacrylonitrile. Technology KOTL for their mixtures have chosen a more expensive, but optimal from the point of view of material properties – original Kevlar, produced by the American company Dupont. On the question of why Kevlar – not produced in Russia, the leaders shrug their shoulders, say, the entire Russian Kevlar is the production of body armor, and all that is available on the market – ground "secondary" Kevlar derived from the contents of discarded armor. The properties of this material is seriously inferior to the "primary" Kevlar, but entitles the manufacturer to proudly write "Kevlar" in advertising.

d-cd.net/e2fa98ds-960.jpg width=960 height=428 itemprop=contentUrl>Full sizeKevlar, metrosert, dust and friction friction ready mix

Kevlar organizes structural matrix. As fillers are used by various barites and chalk. The mixture also includes friction modifiers. For example, copper powder is designed for better heat dissipation and stabilization of friction. Another important component – the so-called friction dust, representing the crushed shells of cashew nuts. This product is used by frilanserami for centuries, produce friction dust in India.

Also in the mix comes metrosert — chopped metal fibers. In Russia this product is in good quality not produced, it is shipped from China (where its made from the Russian wire). The largest European production is located metallisers in Bosnia.

In addition to Kevlar, metallisers and dust friction, the other components of the mixture, the friction (graphite, sulfur, zirconium silicate, barite, etc.) produced in Russia.

Full sizemixture Formation takes place in a special mixer

Full sizemixture Formation takes place in a special mixer

The components of the mixture are mixed in a certain proportion (according to routing) in a special mixer according to the special program. Thereafter, the mixture was allowed to stand, and goes to the shop pressing.

Pressing

This stage starts with pre-production preparation of previously created frames. They are machine shot blasting cleaning – removes scale, oxides, and burrs.

Full sizeBlasting equipment

Full sizeBlasting equipment

Formed surface for maximum adhesion.

Full sizeFrames before and after shot peening

Full sizeFrames before and after shot peening

Next on the frame is applied thermostabilization glue (Russian production). Thus prepared frames arrive on a site of pressing, where the mixture is connected to the frame.

The mixture is poured into is made in plumbing shop special mold (unique for each model pad), then the top frame is installed and the press begins its work.

Full sizeHot shaping

Full sizeHot shaping

The pressing is performed in a "hot" method, in order to have the first stage formed the structure of the mixture out of the original gases, due to the presence in the composition of the phenolic resin. The process is a few "podbresova", a few "prosazovat". With the help of a thermometer controlled the temperature. Also under control is the altitude, to avoid under - or derepression. Computer-controlled program pressing, corresponds to a specific routing – another know-how of the company.

After pressing pads go to the residual thermal stabilization.

Heat setting

The program thermostabilization is the alternation of modes of heating and cooling. The process occurs in a special furnace and takes 8 to 12 hours, depending on the type of Shoe and its purpose. For example, pads for commercial vehicles "burnt" longer and at a higher temperature. Oven works automatically by routing.

Full sizeFurnace for thermal stabilization

Full sizeFurnace for thermal stabilization

The required temperature is kept by using sensors located in the four working areas. In the case of output indicators in the normal range, oven automatically turns off, sending a corresponding signal to a control system. All of the settings and the logs of the processes are stored in the cloud system to which the engineers and production managers have remote access.

In the process of thermal stabilization of the final sintering of the resin and the formation of the structure pads. After that, the pads are almost ready to use – their earnings will be enough 20-30 normal braking.

Producers emphasize that the high performance is achieved without the use of so-called "scorching" — "shock" heating of the contact parts of the pads up to 650-700 degrees Celsius From the point of view of Tver engineers, this "stressful" process does not benefit the pad material, in contrast to another, also used in manufacturing, technology – analog design from TRW COTEC.

A special coating applied to the working surface, allows for maximum friction with the first press of the brake pedal. Due to the high cost of this coverage only applies to "premium" pads (to distinguish them easily on the colored surface pads).

Full sizePads with a special coating do not require running-in and effective from the first press of the pedal.

Full sizePads with a special coating do not require running-in and effective from the first press of the pedal.

But let's not deviate from the topic, because we are waiting for the next stage of the life cycle of brake pads – machining.

Machining

At this stage, is the final formation of the size of the pads in her envelope recommended by the manufacturer of the brake system or of the vehicle, giving it the appearance, the formation of the cuts (to divert "garbage") or bevels (for better grinding and reducing noise pollution).

After that, the pads go on painting.

Painting

At this stage, on the pads, applied anti-corrosion coating by powder coating of a polymeric dye in a tunnel kiln conveyor type.

The process is almost completely automated, which ensures high quality of the painting. The process of passing the pipeline takes about 45 minutes. Then we get almost a finished product – must have accessories and to mark.

Full sizeAt each step, the visual quality control.

Full sizeAt each step, the visual quality control.

Equipment

At the final stage, the marking pad and installation accessories – pumps (mechanical or electric), springs, anti-noise plate. Supplier of the accessories is the Italian company Daico – Chinese components are of uneven quality and are made in Russia only the most simple types of fixing.

It is noteworthy that the markings on the Shoe allows us to trace the whole path for the production of not only specific technological map, but the logs produced by processes of the party.

Pads are rolled up in the thermal film, and then Packed in the carton. Cartons sent to the warehouse, and from there to consumers, but only after samples of the party will be tested.

Testing

Samples of each batch pad routed to its own technological laboratory for testing on a number of indicators.

The test pads on a breakaway, compressibility, thickness variation depending on temperature, the coefficient of friction at different temperatures. Only after successful completion of all tests, the party pad is ready for shipment.

***

Let's hope this report was useful to you. If so, share, write comments, ask questions on the production, technology and pads in the answers, I connect technical professionals!

I see here we have all the terms of the specialists, and CNC versed in metallurgy, powder... where do you all work? Judging by the professionalism of all or merchandisers, or Drivers of carts Magnitsky. And the guys doing his thing and not Bay that the sanctions interfere. Mum, if hands are not able to work!

Subarist69100

Uncle owasa does not clean the matrix, and brings the mold, which by the way the stamp has nothing. Teach materiel, young man, and it looks too stupid...

Check out Mr. where I work and at the expense of the Mat, the theory and practice You are far from my level!

What? No pictures of the production! I'm not even sure that they have the same stolen trucks from Auchan. And they produce apparently small plastic casting. And this excuse to compare the incomparable...

Korneevalex

And uncle uwasa machine cleans the matrix Ulaangom stamp!

Uncle owasa does not clean the matrix, and brings the mold, which by the way the stamp has nothing. Teach materiel, young man, and it looks too stupid...

TochkaOpory

Movie looked. And about the pads where? Forgot the topic of discussion?

Objective information was given. Then each goes his own way. Anyone interested in such a thing for a manufacture to buy Googles, finds and buys. And to chew and put my mouth here you no one will.

Ie Instead of objective information, only the demagoguery. But expected...

Teach we all know, this work just fails

They can't cost as much as a floor press. You have to — you and Google.

And special equipment is not always cheap.

And this is the production of a good boss garage from the stunted plant with carts and machines of the 50s. Savings on the comfort and convenience of employees.

But what if people recommend? Maybe they are like the floor press with CNC? Don't know don't make any noise, and answer for the words

No idea, it is a special equipment, its on every corner in the store did not sell, and I do not do it.

RedAngel

You are not quoting the message on the buyout and answered.

In the first message I gave an example, accessible to everyone.

But the fact that you replied I already gave an example closer to the present situation.

Anyway — the bottom numbers to get uncomfortable. And there is a special truck, which specially for such tasks are used.

But if the employer values its employees — that he will purchase the truck with a spring-loaded bottom. They are not super expensive, but due to its design as the devastation from the bottom rises above to, the employee took the details with same stomach-chest.

On the production did so, among other things.

Throw Contacts, where to buy cart with a spring-loaded bottom for cheap! I'll take a dozen service, perhaps...

vk5687

Hmm...since 2011, and the engineers and that 2014 and consider themselves smarter than others "zeroing" of checking the quality of some tests. Not necessary, not necessary. Well, OK, Tversky engineers know better...

And you to the author list of test sketch, it will give the production. You see, and not thrown out, huh? Or you do not know about what write?

Good day! Came across this article and wanted to learn about the production of those pads, which drove more than one thousand km.

I must confess I was surprised that the production involved a small number of staff. What is the reason from article did not understand. Maybe in 5-6 years the production starts gaining momentum, and perhaps a larger number simply not required because of the well-built cycles. By comparison, the megafactories the company has several thousand employees! And it did not hurt to be on the verge of bankruptcy and to ask the government additional grants.

rostov.dk.ru/news/rostsel...nnoy-podderzhki-237085005

Or, for anybody not a secret how several years the government subsidized LADA.

www.kommersant.ru/doc/3350861

Of course, LADA last time resuscitate )))).

OF COURSE!

It I to that so-called strategic giants without public money, taken from taxes, would have long since dived into oblivion.

You can only give a standing ovation to the courage, determination and purposeful actions of Russian investors and entrepreneurs, which in conditions of the protracted crisis in the country, going forward, developing industry.

Let there somewhere in the photos of the plant we see is not what you were expecting. However, I have been to several factories including defense enterprises. And believe me, skeletons in the closet is even there, maybe billions.

Well, it's the lyrics.

The main thing is that production, again in my opinion, the quality is not inferior to many fairly well-known branded manufacturers.

I have tried many well-known brands such as textar, trw, ate

...the same remsa tried. Yes all and I do not remember. I only remember the feelings... were Satisfied or not. And when 6 months ago I found Kotl, I was pleasantly surprised. There is no feeling that pad hard enough or dusty, creaking.

Product quality was pleased.

And I want to add that for a GOOD RUSSIAN products are as happy as the athletes acted and won a prize at the world games.

Good luck to You guys! Keep it up!

NERSKY

Yes-Q now stand as the plane. In the beginning of last year I took myself in front of Antara for 1,100 rubles, and now it's time to change - again, I wanted to take them... and the price tag is almost 1600 wood? as well as TRV... so Here business is done in Russia - a little hyped brand and from +100% cheating.

katalinic throw off, I will look and cost exactly say yes-q

gansT80

Rasmine))? Ie on a new car are the shock absorbers Boge. If I buy the Boge, not in original box, I buy is worse quality than the ori box)))))?

Broke ori headlight Hella. Bought new, the room is old. Bought Hella in Hella box, but not inside the VAG. Around the world there is no difference. So I bought the wrong stuff)))))?

A resource is any component from below the conveyor part at least.

A few words about the stocks of the Russian manufacturer Ketl.

avto69 on the website

Alex Vishnevsky

I drive Renault Logan (2nd generation)

Tver

Hello! I would like to share with You my thoughts and concerns about the quality pads of the firm Cetl. I have read many of the comments here leave much to be desired! How to describe in obscene angles production cycle and environment the company is not faced with it personally? Often the reviews about this company write about an awful situation at work (dirty clothes of workers, antiquated machinery, shopping carts on the corners with blanks...etc) Friends, what do You write? In my example, was able to personally attend the production of brake pads Cetl and make sure that I personally trust with my car, and as for the brakes, and your life! During the last 2 years I only use pads from this company! Yes, I admit initially there were complaints on the quality (in particular the "whistling" pads), but it was at the initial stage of formation of the company! Now, I in no way satisfactory quality pads Cetl! As I wrote earlier, I was able to visit the factory of the company Ketl! I want to notice, the first thing that I immediately caught my eye when entering the trade, it is a reasonable and rational placing(though not in large areas by my standards) as of the workpieces and placing the finished product on the output line painting(final destination of the production process). On a rather small area of the shop, clearly marked zones for the collection of blanks for production, areas for collection of emerging products for laying them in semi-and areas, products have directly to send on a line picking and packing of finished products. Please note that all this is organized on a pretty "not vast areas"! Further, the equipment is mostly made in Taiwan(please note not China) and it's still in excellent condition! I also met a number of machines of the Russian production is pretty decent! Workers, I have never met such friendly and kind people! My questions were always the answers! But for me it's like the common man is not important enough! I managed also to communicate with the managers of the company Cetl, adequate, professional people, exactly who know their business! Next, I continued in the Department Picking and Packing of finished products, here I have made it clear that the work really "special". When picking a brake pad is "triple" the quality control of the released sets! As the visual system upon detection of defect painting, friction mixture, the curvature of the frame, etc., and the marking on frame selection and riveted necessary accessories based on these routings! All of this careful hands wrapped in shrink wrap in the shrink machine and is Packed in a colorful box(the design of which is also developed by employees of the company Cetl)! And in conclusion, I want to add from myself personally, friends are not convinced on their own experience of exploitation, brake pads Kel, I ask You not to clog the blog "unflattering" and "non-professional" reviews about this producer! In the future, I want to wish this young Russian company Cetl under the formation of SUCCESS AND PROSPERITY IN THEIR hard WORK!

Very interesting and honest article. Guys don't hide their technology and production stages of your product is a big plus. I agree with the author above about the processing industry. Raw materials in bulk, and make it a finished product, alas, can not. But this problem is not only the industry, but throughout Russia as a whole. I hope that once and it to learn how to do) Most are accustomed to the principle of "if the goods are cheaper means lower quality". I see no reason to overpay for foreign pads, if not worse than domestic. Finally, the Russian product at the ratio quality-price is very pleased.

artemspec

It is not so. The fact that the manufacturers have specific requirements for conveyor spare parts, there are other requirements and tolerances, any deviation is punished by breach of contract. In the Annex to the pads and other mixture, and quality control, and everything else. That is objectively pads for the pipeline much more expensive. And aftermarket can be what you want to put, if only somehow impeded))) For suckers savvy sellers invented the story about the "pads from conveyor belt manufacturer in other boxes" surprised that people believe it...

Well, I can't agree. The pads on the conveyor/original manufacturer car plays the role of OTK/packer, giving to outsource the role of production. But this does not mean that the manufacturer of shoes devoid of QCD and is completely under your brand to sell complete junk.

Mktone

Lutchshe, so lutchshe. Such arguments simply impossible to argue. What were the arguments, Bravo!

That's for sure. It was at times lutchshe )))))

RedAngel

Lol. What's this?

PS — here is his ad read people more than native blog ))

Sell moped! Cheap! Details in PM! ))

Evgeni-Efimovich

Thanks to the Author for a great article and worthy of pictures! Honestly, I have not read such a positive report. The more that buy these pads. Well done guys, good luck! The first time I bought pads at the recommendation of a friend mechanic. Quickly ordered online by VIN number kotl.ru/ru/podbor-tormoznyh-kolodok he me put. Particularly pleased that stood up the first time, did not deliver the hassle. What I want to say in conclusion, gentlemen, if You value time and value the money, note CETL! All easy ways!

Another Troll, EV, bailed is merged.

Evgeni-Efimovich

Thanks to the Author for a great article and worthy of pictures! Honestly, I have not read such a positive report. The more that buy these pads. Well done guys, good luck! The first time I bought pads at the recommendation of a friend mechanic. Quickly ordered online by VIN number kotl.ru/ru/podbor-tormoznyh-kolodok he me put. Particularly pleased that stood up the first time, did not deliver the hassle. What I want to say in conclusion, gentlemen, if You value time and value the money, note CETL! All easy ways!

And Cayenne is:)

Thanks to the Author for a great article and worthy of pictures! Honestly, I have not read such a positive report. The more that buy these pads. Well done guys, good luck! The first time I bought pads at the recommendation of a friend mechanic. Quickly ordered online by VIN number kotl.ru/ru/podbor-tormoznyh-kolodok he me put. Particularly pleased that stood up the first time, did not deliver the hassle. What I want to say in conclusion, gentlemen, if You value time and value the money, note CETL! All easy ways!

Mikhail-Utrish

Wow — copper wool friction... ;))

Interesting. As it is not ran like that. I will keep in mind.

Copper powder !

Pads company Just Drive such) Go long, the price is low, farmers appreciate and then change the disks once in 40-50 thousand, and unhappy... quality of the disc)

After reading the article, as much soul rejoices that the Russian market appeared a quality product. So for reference a few years ago changed the pads. I salesman in the store persuaded to take foreign, as to domestic wear faster and generally leave much to be desired. Well, of course, and the price difference decent. Now I will take Ketl. Judging from this "transparent" production, their products can't be bad! By the way, and automation at the highest level, which allows to make a modern and competitive product.

for VAZ Samara 350R kit front. Rules, if the quality is acceptable. For example, air filters in Saint-Peterburg produced by another firm known for foreign cars and domestic cars. So the difference in price and the quality of the paper.

I asked them: "what !"№;%:?" why is it so different? "

Answer: "because the task was to make the domestic as cheap as possible, even at the expense of quality."

Good to be here "mixture" would be the same...

Torres15

Fair enough, but I as the end buyer, these numbers and laboratory experiences are little understood and quite interesting.

Much quieter to put the REMS, TRV or Brembo and not think about the numbers and graphics.

Forgot about Ferodo

Korneevalex

I don't know and don't want to know about Belarusian Stellox ( note I from Russian Baikal). I have written about production...in Belarus there is a company Fenox, which has been doing for 30 years auto manufacturing RFP and that it has been supplying across Russia the goods ...and the quality is not ice...that's the whole example. and never such production can not afford a good laboratory ...to quality and industry that Belarus is that Russia is like the moon of (zroblena Belarus) Brest I only buy socks ...

By the way, Yes, socks scoring

"the Italian company Daico"

maybe all the same Dayco? by the way, its power production in China :)

well anyway, it's a business, not just manufacturing. More exhaust at lower costs. And with so much competition and a low price will the quality? I will not argue, these pads have not tried

NERSKY

Yes-Q now stand as the plane. In the beginning of last year I took myself in front of Antara for 1,100 rubles, and now it's time to change - again, I wanted to take them... and the price tag is almost 1600 wood? as well as TRV... so Here business is done in Russia - a little hyped brand and from +100% cheating.

The plane is 1600 rubles? :-) Something tells me that the ATA or TRW, even the simplest, will be more expensive.

Want to fly into space, turn on some Patriotic channel on the TV. I personally price the pads closer.

Guys are trying, but this is not a factory, and the factory, a drop in the ocean. Let's hope all of them will be good. But while China wins. About the quality, there is no reason to believe that our better or worse. While I was protectionism, it was all awful and expensive. The market is still in China (I think under any import).

I want good pads for sane money. I do not know what there may be for 15,000, as well as and then there poured hardworking ketici 200. It was worse? maybe, but in space the fly! And these guys try and like it. At least sufficiently clear and easy to understand, and from what. And their pads are cheap because the same Eastern neighbors in the bucket...but switch it up and lay it over trains. And here is the question: will it be slow? what a beautiful box to print the Chinese obtained is not a secret for anyone. And inside?

To nefteyuani economic geniuses do not reach. Just to do things for themselves, as under Stalin. Doing it all yourself: USSR, Cuba, North Korea. And they are all deep in the ass.

Manufacturing in China does not require such capital investment. Shop from cardboard, heating is not needed, the environment is not needed, a billion slaves of humanoids on the conveyor. Why not make all the way. The rest of the policy.

Regarding the structure of our exports, I have no idea. I think you, too, although fighting here.

See around, everything is bad. But his production was worse. You want the pads for 15 000 rubles, and not 1500, for example?

That's what I, unfortunately, mean. If we traded rocket engines and even in rubles, I'd support it 100%. And so, you see, maybe the pads to trade start. And if you renew your chain, it turns out that rocket engines are easier in China to buy! For nefteyuani.

Homework, prolong the chain: where did we come from dollars or yuan?

If you mean that we sort of sell the raw material instead of rocket engines, then it is certainly bad. But this was not the speech you the fact that trade anything not liked

Everything seems beautifully painted, as much wanted to live! Only here the hitch and one for the Chinese your RUB fuck not rested, they sell everything (including pads) for the North American dolerite, at least for the yuan. And that's where you take them — never their problem. Here and sell oil and gas instead of developing our own production!

You ask yourself. Essentially: cityu sell us pads to get Russian rubles. Where will they get the rubles? Ass tucked, or buy them something? If you buy, then what? Something Russian, right? Because RUB what? Russian ruble. It turns out, they give you pads, and you give them rocket engines. Not be pads, not the engines. Money is just a way of exchanging goods and services in the end. And you don't like money, you want a natural economy, when every yard ppoizvodit everything myself, from shoes to soap. Just because you're very smart

Well, don't be so mad. Write to the Minister of the economy, maybe his eyes will open. Well, at least the Chairman of their collective farm. Here you feed in the farm shop? Why? Produce yourself. Tractor is also for yourself. Don't be a fool, go for it

Foreigners don't have buying anything from you. They have no reason to. No. They are interested in a paid for commodity money, need a market. Where to spend the money and so they will find. The country of your them, as you call it, did not give fuck. And production, working in their own country pays taxes and creates jobs. The people working on this production, to live in this country, pay taxes, and most earned it and spend, creating demand for a large number of goods. It seems simple and clear. What does the phrase "So nothing changes, in addition to efficiency and competition instead of protectionism."? It is wryly expressed a thought or stream of consciousness? And you chewed with "umami ekspertami" if any simple things to understand or to formulate thoughts can't?

If you do that it buys from foreigners, they will have the money to buy something you have, otherwise why the fuck would they need the money. This is something you will. So nothing changes, in addition to efficiency and competition instead of protectionism. All tired to chew umami ekspertami basic economic laws

slavatb

Would be better if there was a stock Chinese pads, and managers instead of engineers and skilled workers?

The better trade of foreign goods the production of this product in your own country?

About them to read is not funny. But this particular article is very funny.

The first thing that catches the eye — in the beginning of this article expresses a negative opinion about the use of "not original". And here is the same is the same "not original". That is not the original ATA, fedoro, brembo worse than the one described in the article?

If you take for example the TRW pads that go in my car as the "original" pack of Vaga, and in ordinary native packages, then at least I know that it is all one line, and it's the same pads. these pads from the article except physical persons are not implemented. And their purchase — the cat in the bag. Only if there is a bunch of positive reviews. But by these pads not very, not to mention the comments to the article left by people who by all indications are uchitomi ephemeral, and their texts are not very different from advertising copy to various Newspapers. here's an example —

"After reading the article, as much soul rejoices that the Russian market appeared a quality product. So for reference a few years ago changed the pads. I salesman in the store persuaded to take foreign, as to domestic wear faster and generally leave much to be desired. Well, of course, and the price difference decent. Now I will take Ketl. Judging from this "transparent" production, their products can't be bad! By the way, and automation at the highest level, which allows to make a modern and competitive product."

NORMAL people do not write to praise the product and not poprobyvav it? it is the magician-the magician determines the quality of the product and production photos?

DimaShy

What is sudep plant? More than 58 people and components from China - funny

The production quality doesn't have to be big. Abroad there are brands that produce cars (and only cars) for the secondary market by the superior quality of the original. They do not put on the line just because they do not have the production capacity to meet the needs of the line automaker. The number of workers there is similar, too funny to read about them? Go to the website "Lobaev Arms," you too funny?

Korneevalex

On the Bosch there is no such ancient hardware! And Your trade does not cause all who are associated with CNC And Metalworking. I took a very long time and forgot and the first ProEngineer programs and so on. So don't see the point of those parts to discuss!

well recommend ? worth taking? or gon ? right now are mintex .happy.

Have a cheap shaft not so much with the shape of the Cam issue, but with a quality shaft because the problem is still there) edit profile kulock just let this piece of shit to serve a little longer, so shamefully little of the camshafts only go at the classics

I did not argue, he went on their shaft, the workmanship is excellent. besides, the Director himself, in his time on penny Vase has upgraded the camshaft, which initially Cams are not properly calculated and was quickly worn out...

Serjant02

in Ufa there is a firm OKB Engine, the former Masterbator. They make aftermarket camshafts for cars in the sport have credibility. Now, they manufacture approximately you described the place is, machines of the USSR, some CNC but the products are high quality and in the world of sports and easy tuning not bassista.

And I dare say they have shafts better tuning AVTOVAZ, as the grant activities (blunt surfacing stock shaft), and the years of issue of machines is in principle a huge role to play, of course depends on the scale of production, they upgraded and calibrated. And the CNC of the USSR almost all of them are with modern control electronics, as with the cards no longer work)

With pots, it had to have a paradox here — stand SHAAZ, which are pipeline — very high quality, the need for comparable caboy, but the difference in the characteristics of the gas oil Kayaba work slightly differently. If not the pots to take — for example on the Audi stand Bilstein go better than the original SAC)

well, in the case of the pelvis, the Kayaba W-neoriginal, but better than the original, probably) and the bearings are SKF-almost always neoriginal, but good

Zarik-Autsaider

Well, it is not clear until the end of the initial thought-whether to buy norinyl?) overall, I believe that good neoriginal can't be worse than the original parts Well, and not always change the pads at IT, because they change when the wear is more than acceptable)

Worth it, but the quality, the factory pads usually does makes their subcontractors, and the subcontractors in sells of spare parts under its own name, such parts are no worse than the original. There are doubles, surpassing the original, but generally more expensive, it turns out that what the firm can do high quality the item, but the scale of production can not meet the needs of the plant

TochkaOpory

buy used for pennies, apparently not destiny.

You're so vain to trucks) I use them in Boxing, is very convenient to use and are inexpensive — they are very easy to clean items, for example) Trashcan of them are excellent, storing small things)

Take the pads marked FF from famous brands. I had some ASIMCO (went from a/m) braking is started normally only after a few good atternative, without the brakes almost was not. Set Textar — brakes appeared.

DIXCEL type Z

Juzaju such at the moment

Because some who makes a normal pad, no excuses with reference to mutually exclusive factors.

About the race conversation was not.

---

I need to fiercely retarded, not much warmed discs, and worked well in a wide temperature range

---

Forgot to add "sanadora" ))) you can say mutually exclusive factors. Saw on the racing brakes warm up? )))) here there and braking is "fierce".

I will never not buy these pads, because there is no useful information here, I did not see it.

I need to fiercely retarded, not much warmed discs, and worked well in a wide temperature range,

I'm just going to buy on their own criteria, but unfortunately from another manufacturer, and I don't care how they were painted)

Well done guys, I hope they will find their buyers.

Sixty eight thousand one hundred

So as always. The Japanese still nobody surpassed. Put on your Nissan Japanese . AKEBONO

The only thing no one surpassed nipponzan is in their ability to do Hara-Kiri and fall in "the eye" on us carriers )))) all that is in the industry invented by Europeans, and the Japanese and the Chinese are in fact only "copiers".

Sixty eight thousand one hundred

Brembo and TRW .

No one will argue that it is a good company.

But like I read somewhere that they should be, and discs of the same company to put. I am on my disks was about 100 000. and faded just less than half a millimeter.At the same time as they walked up to me, I can't answer. The speedometer 400 000.

Brembo I put the drives from them quickly dirty.

Well Yes... the caliper mainly in European (and other) models do ATE, Lucas/TRW or Girling. Brake pads and brake discs on the conveyor put those companies which were tender, for VAG, for example pads can put and ATE and Textar and TRW, with "quality braking" the official guarantee no matter who is the provider in a particular year.

Very "dirty" rims indicate that the brake pads are soft and wear away quickly, so more gentle to the brake discs that will last longer.

Brembo and TRW .

No one will argue that it is a good company.

But like I read somewhere that they should be, and discs of the same company to put. I am on my disks was about 100 000. and faded just less than half a millimeter.At the same time as they walked up to me, I can't answer. The speedometer 400 000.

Brembo I put the drives from them quickly dirty.

Sixty eight thousand one hundred

So as always. The Japanese still nobody surpassed. Put on your Nissan Japanese . AKEBONO

Are you sure? What I have not heard of your firms manufacturing, but that's about Brembo, Lucas, ATE, Ferodo.TRW does not know just lazy.But this is the best Japanese pads Allied Nippon.

So as always. The Japanese still nobody surpassed. Put on your Nissan Japanese . AKEBONO

The first few times until the brakes are warmed up brakes like fuck knows what. Then that's good. Quickly overheat and begin to swim. Especially on heavy cars.

Not our equipment, design, materials, even packing in Russian did not bother to do. for reviews creak. The conclusion for me is - what is necessary.

SuBaRuGuRu

A weighty argument. Then Ashot and Bosch (video below in comments) surpassed. Upload pictures of its heat press machine with CNC for 40 mil, its raw material with Kevlar and laboratory and apply the scan tests from US with the level of characteristics is endless RC5)))

Where are these photos, or only idle talk.

well, first of all the graphics these pads are shit, and no such models have endles)

The article is very interesting, the pads are not know or enjoy never, but for the enterprise happy, and the fact that it survived the crisis and work to date, a small business has the right to life!

Prosperity, good luck and great competitive pad company.

Cool article, great praise of fakes without BJ and all zaregineny??? a month and a half ago, pachani promote their products)))

PS If PR, so do it in the real tests on the rally tracks, become sponsors, show to fit your products.

the interior of the plant interesting, like something from the"covered underground shop"

Hmm.how would I get to them? There is a proposal B2B.

Cutters, inserts, drills, etc sarovskoe Sumitomo Hofmann and etc.

Manual processing on the machine without respiratory protection? Taking care of employees? Not heard

A month ago I bought a Range Rover Sport

in service on West LR test.

Feels no different from the original which was before! Read a lot there not to understand reviews. But in fact after a month of use, no complaints!

Keep it up! Let the Russian trade is rising up!

Full size

Full size Full size

Full size Full size

Full size Full size

Full size Full size

Full size Full size

Full size Full size

Full size Full size

Full size