Replacing Lift Bolts - Toyota Celica, 1.8L, 2003

And so that everyone would understand which elevator I ride, let's start with theory and history.

The 2zz-ge motor that stands in the heart of my blonde.

The first 2ZZ-GE, created with the help of Yamaha minders, entered the overseas market with the new Celica 231 in late 1999.

Volume - 1795 cm ^ 3

Max. power - 192 HP at 7600 rpm

Max. torque - 180 Nm at 6800 rpm

Compression ratio - 11.5

The main pride of the minders was a new aluminum block based on MMC ("composite" with alumino-silicate fibers and inclusions).

I will not describe for a long time how this modor was made of gold, about its thin walls, etc.

Better to go straight to tell you about the elevator.

Actually the very same inscription on the plastic of the VVTL-i engine - Variable Valve Timing and Lift - variable valve timing and valve lift .

The VVTL-i mechanism itself is quite simple. For each pair of valves on the camshaft there are two cams with a different profile ("calm" and "aggressive"), and on the rocker there are two different tappets. In normal operation, the rocker (and valve) is driven by the still cam through the roller follower, while the spring-loaded sliding follower is idling, moving in the rocker. When switching to a forced mode (more than 6200 rpm), the oil pressure moves the locking pin, which supports the sliding pusher rod, rigidly connecting it to the rocker. When the fluid pressure is released, the spring pushes the pin and the sliding follower is released again.

In a nutshell - up to 6200 the motor has a normal shaft, after that it is humped.

The most unreliable part of the circuit was the locking pin. It cannot get into the working position in one turn of the camshaft, therefore, the rod inevitably collides with the pin when they are partially overlapped, from which the wear of both parts only progresses. In the end, it reaches such a value that the pin will constantly be pressed by the rod to its original position and will not be able to fix it, therefore only the low speed cam will constantly work. They fought with this feature by carefully treating the surfaces, reducing the weight of the pin, increasing the pressure in the line, but they could not completely defeat it. In practice, the axle and pin breaks of this ingenious rocker still occur.

The second common defect is that the rocker arm axle bolt is cut off, after which it begins to rotate freely, the oil supply to the rockers stops, and the VVTL-i, in principle, does not go into forced mode, not to mention the violation of the lubrication of the entire unit.

Here we will dwell on this bolt in more detail. The price of replacing a bolt is ridiculous, the price of repairing an engine after a bolt cut is deplorable.

Therefore it is decided! change the bolt ... yourself!

First, we need to purchase the elevator bolts ( 90105-06293 , 125r) and sealant (200r). Then, wash the car and under the hood (what for we poke around in the mud ... and indeed it should always be clean there)!

Then we move into the garage, parking lot or somewhere else. Open the hood.Naturally, it is desirable that the car was cold, so as not to burn yourself

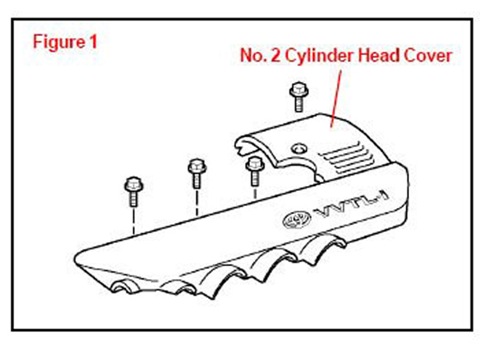

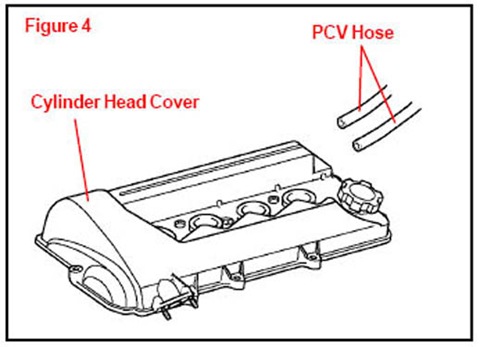

1. Unscrew the 4 bolts of the VVTL-i plastic cover. For this you need a 6-sided wrench.

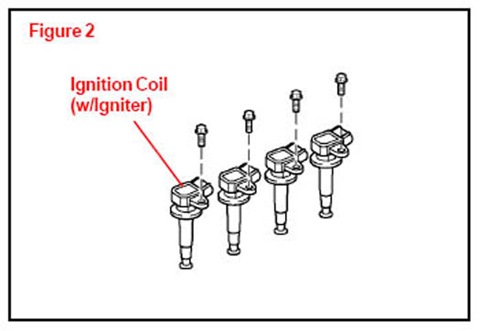

2. We unscrew the 4 bolts of the plastic candles (hz as they are called). Here and further we will need a tube for 10, or something like that. We unscrew ... we take out.

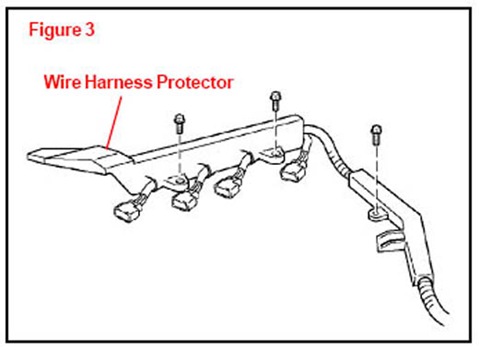

3. Further, as shown in the figure, unscrew 3 more bolts and remove the plastic mask with the wires. I must say right away that I could not completely remove it, because did not find where the wires are disconnected. But in principle, and so it did not interfere much.

4. Disconnect two hoses on the right, there is a usual latch. Although, in principle, they just pull away.

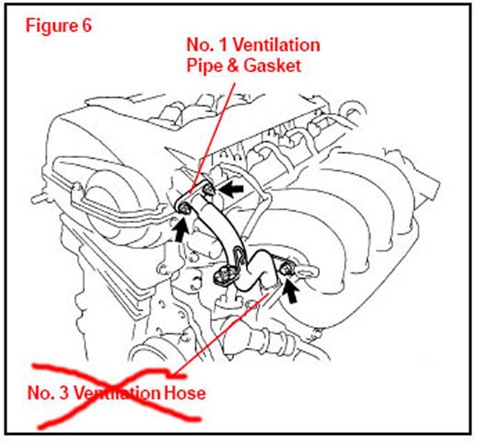

5. Unscrew two more nuts from the tube mounting as shown in the figure. We do not touch the third nut, we do not need it.

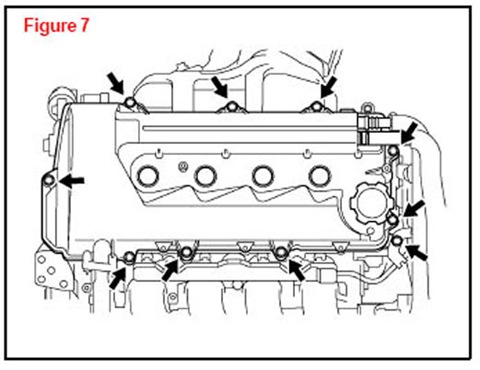

6. Now unscrew the valve cover bolts. There is one peculiarity here ... You cannot crawl to the bolts closer to the windshield with any tool, so I advise you to first make sure that these bolts will actually be unscrewed. Although, in principle, I climbed there with a tube. Then, if the cover is dead, we pry it with something like a screwdriver ... open it ...

And we see ... (I really took a photo after I screwed in new

7. Then we unscrew the old bolts, admire them and screw in the new ones.

We close and go :)

Now we do not think about the fact that something can happen when we turn the motor. Only ... the more often we twist, the more often we check the oil :)

good luck to everyone who climbs into the engine following my example :)

Price tag: 325 ₽ Mileage: 65,000 km3s-ge, one of the most reliable Toyota motors

and 2zz ... it's from a falga :)

I didn’t change myself… I have toothless 1zz.

Just a lot of homies, 2zz… and so they saw the corpses!

… Count yourself pinned up, the guy is driving on a flat road. The fourth 8000… and instead of 5 he sticks 3… the exhaust valves were lit up. About 15 repairs with spare parts got up.

2zz does not have a safety margin, the same 3sz would most likely survive in this situation

Well, yes, I put silver ones (I did not pay attention to the color, I thought that they acquire the same color as in the photo as a result of operation), but visually they are very similar to those in your photo.

The system itself provides for Variable Valve Timing and Lift two-mode valve opening. First: idling and low speed up to five thousand - mechanical. The second revolutions above five thousand are hydraulic. And the degree of valve opening is regulated hydraulically, that is, by oil, through the oil control channels for opening the valves, but over time and due to the quality of the oil, all these oil control channels for valve opening tend to clog. The oil solidifies in the oil control channels for valve opening in the engine head and turns into jelly-like sausages. This does not affect the wear of the parts, but the Variable Valve Timing and Lift system itself stops working more accurately only in the first mode.

That is why they say that this 2zz motor is capricious for oil, and since in the CIS countries, even if you take the original, it is not a fact that it is good, you need to periodically remove your head and take out the sausages :)) to feel the full power of this motor.

After the work done, I switched from the original to Motul, it is not yet counterfeited, and the system of its sale makes it easy to calculate a fake.

Can you show in the picture where exactly to pick out sausages?

The second mode, hydraulic, starts at five thousand, even a little earlier, and at six thousand, the valves are already fully open and maximum power is available. In addition to the fact that, like all high-revving engines, it does not like a low level, this engine is also picky about the quality of the oil, not high-quality oil solidifies in the control channels for opening the valves.

the elevator turns on at 6, and not at 5 thousand

at the expense of oil ... this motor is capricious to oil like any high-speed one, usually with a low oil level it turns the liner ... well, then. how lucky ...

Well, yes, I put silver ones (I did not pay attention to the color, I thought that they acquire the same color as in the photo as a result of operation), but visually they are very similar to those in your photo.

The system itself provides for Variable Valve Timing and Lift two-mode valve opening. First: idling and low speed up to five thousand - mechanical. The second revolutions above five thousand are hydraulic. And the degree of valve opening is regulated hydraulically, that is, by oil, through the oil control channels for opening the valves, but over time and due to the quality of the oil, all these oil control channels for valve opening tend to clog. The oil solidifies in the oil control channels for valve opening in the engine head and turns into jelly-like sausages. This does not affect the wear of the parts, but the Variable Valve Timing and Lift system itself stops working more accurately only in the first mode.

That is why they say that this 2zz motor is capricious for oil, and since in the CIS countries, even if you take the original, it is not a fact that it is good, you need to periodically remove your head and take out the sausages :)) to feel the full power of this motor.

After the work done, I switched from the original to Motul, it is not yet counterfeited, and the system of its sale makes it easy to calculate a fake.

what kind of sausages in the canal?

bolts of the third generation are already silver, and slightly different in shape. The first is not so hot. Yes ...

I don't know about the third generation. I only know that there are two numbers, and the manufacturer recommends placing a replacement at this number 90105-06293 .

I ordered a dozen of these bolts from an official, there the price is 60 cents apiece, they are very similar as in your photo, and those that were removed were completely blunt, so only a slight rounding.

Well, did you get into the canal with butter sausages?

We really knocked them out! No flushing helped!

I know all this

and in general, there are 3 generations of bolts, 1999-2002, 2002-2005 and 2005- to this day, as they say, the last gen 3 (generation 3)

they have one number, just gen 1 and gen 2 are no longer produced

in the photo old, 2nd generation, new ones delivered 3rd generation

You changed it beforehand, it was not a big problem.

By the way, these bolts were changed in 2003, because initially they had some kind of constructive revision and the manufacturer recommended on old models from 2000 to 2003 to replace the bolts of later Selica models with the number 90105-06293 visually they differ only in that, that the older ones are more blunt, unfortunately I don't remember the number of the old ones.

If these bolts break, and the old ones broke very often, the system stops working correctly, that is, the valve opens only a quarter, as at idle or during quiet driving, the second drive mode does not work, the following problems result from this:

1. This is a significant loss of power ...

2. This is a break in the gasket under the head.

In addition to breaking the bolts, clogged oil channels in the timing system can lead to such problems.

Specifically, only one of these bolts was broken, but the bigger problem was that all the Variable Valve Timing and Lift oil channels were clogged and, accordingly, the valves were opened only in one mode mechanically, and the second hydraulic mode did not work, as in the case with broken bolts.

Only after replacing the bolts and rinsing or, more correctly, knocking out the sausages that used to be called butter, I could feel the beauty of the 2zz motor. The car began to pull out the asphalt under the wheels! Just not a real feeling from driving before, as she did not press, she did not ride, I tried the manual mode of gear shifting, and everything, as if someone was holding the tail, but after preventive maintenance, she flew even on the machine! When the mechanic finished the job, he immediately warned - Now use the pedal carefully, because when you press the pedal sharply, thanks to this Variable Valve Timing and Lift system, you will instantly jump 70 horses.

This type of gas distribution Variable Valve Timing and Lift BMW on its 8-cylinder engines began to be used only since 2003, and on 6-cylinder and even from 2005 at BMW it is called volvotronic, I don’t remember the exact term. H

Thanks a lot for this post! There would have been more of them) Now I also decided to change

And for lamers in the drawings, you can use a manual - how to pick out sausages and where from? :)

the head is 10 or 12, I don't remember exactly, you can look at the motor

like nothing else is needed ...

Tell me what tools are needed to replace the bolts, I just think it's better to buy the necessary tools for yourself than to give 1500 in the service!

in the photo there is a white bolt 1 cm to the right of the chain, and the second one is lower, but only half of it is visible

why didn’t taste it at all ...

what kind of bolts I changed ...

you can circle them in the picture (for beginners) please ...