Knock on the suspension - Toyota 4Runner, 3.0L, 1995

We skip again to the beginning of autumn. September. My father's vacation is over and now he comes on short visits.

Once again, my father comes to the village on the weekend. Mom and I are returning from the forest, and he is again tinkering with the car ... I don't remember what ... with some nonsense ... But he finished and finally comes to the left front wheel and shakes it ... then knocks on the kangarin ... then leans on the right wing and rocks the front end ...

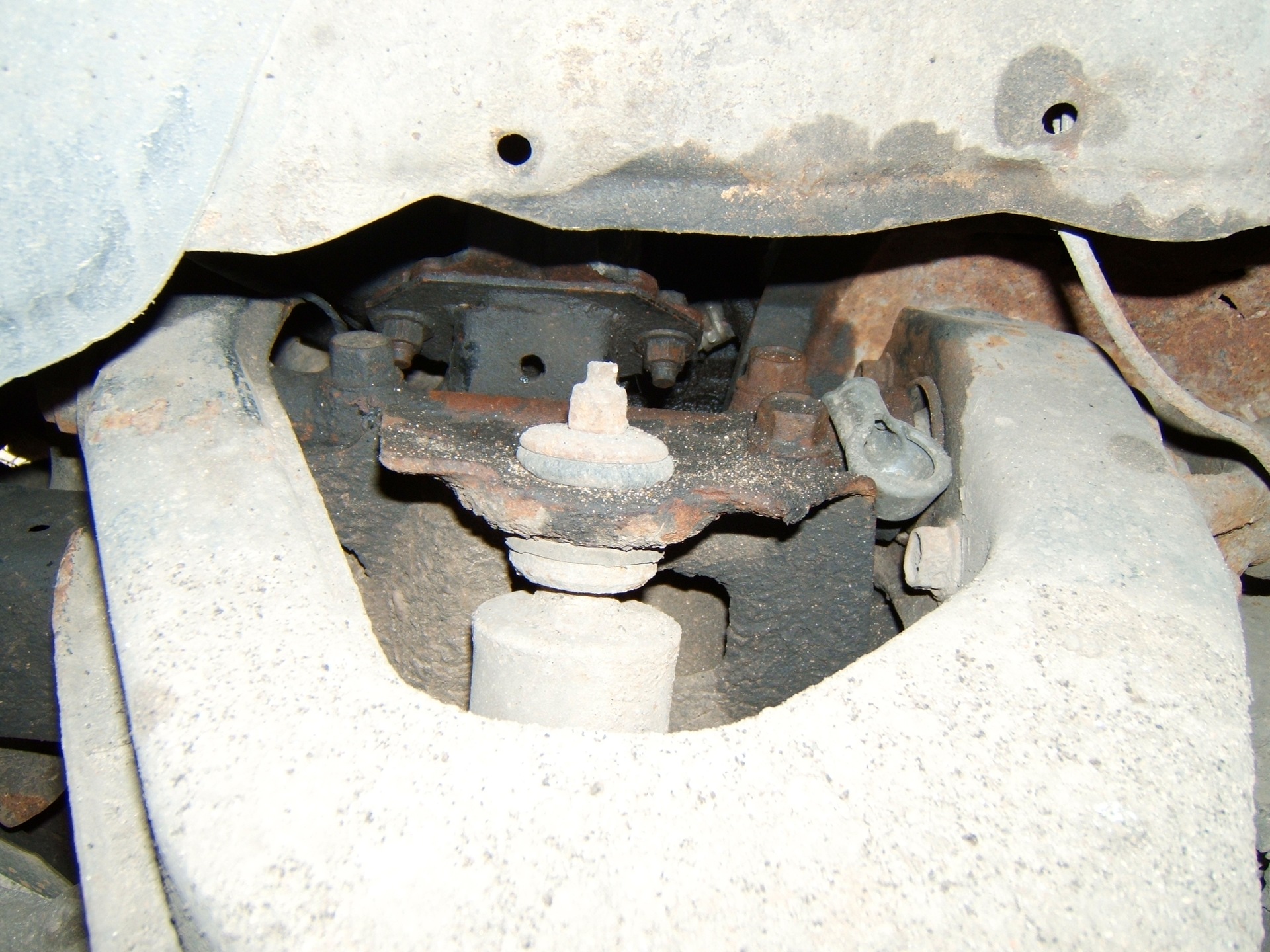

ABOUT! I hear. Some unpleasant metallic knocking in the bowels ... I look into the wheel arch behind the wheel and ... I understand that the upper point of the shock absorber's mounting bracket has broken off. When the car rocking, the morter dangles in the space of the suspension forks, jingling pipes, and a piece of the bracket and the rod hammer against the mudguard of the engine compartment and rub along some hoses. And there the brake pipes are close, and the pipes of the kondeya, and the pipes of the gidracha: if it punches / wipes something on a bump, it will not seem a little.

This is how the morter broke off:

Here is the break point on the frame:

And this is how it should look initially:

And what kind of attack such ... my morter fell off on Takh, now my father's ... But I have springs ... they are quite tough without load, so the absence of a morter is not particularly noticeable. And my father's torsion bar ... and even hooked, and therefore soft ... it will be unpleasant to drive on the "washing boards" of our roads.

Naturally, we decide to remove the morter before welding, because there is still nothing to do - there is no welding at hand. Yes, yes ... just welding. Structurally, this bracket is made as an amplifier at the point of attachment of the upper suspension arm and subframe to the frame, and its console is a support for the shock absorber rod. And this booster is welded to the frame side member.

Ultimately, the welder was found. One relatively warm October day, we went to my friend, who is repairing cars, who has long been inviting me to visit him, whom I drove past all the time on the road from the dacha (because not before "visiting"), but from home it was just too far away ... In general, somehow it was not possible to agree and call in. And then he just also needed the head of a person navigating computers (this is about his father and a little about me). In general, everything came together one to one ... and the weather, and mutual necessity and free time ... In general, we went to him.

While he was welding a piece of the bracket, we conjured a folder with his computer. We set up a program for testing BC machines for him ... We talked in parallel. We talked about life ... He showed how he arranged a house, a bathhouse, a garage, a repair room, a paint brushes ... In general, the guy is great!

Well, the bracket fell off because ... apparently, the previous owners beat the car great ... Either there was an accident (the fenders and hood were repainted, obviously) with a blow to this wheel, or there was just a strong blow to the suspension, or a mortar with a stake I got up sometime ... I came to such conclusions due to the fact that I found traces of untidy handicraft welding on the bracket (you can see it in the pictures) - it was from them that this bracket broke off.

Well, it's okay now. My friend did everything well. In addition to the actual welding of the fragment, he also welded overlays on top so that it would not break off again by welding in the future.

Unfortunately, I could not take a picture of the result of the repair, because I forgot to take my camera with me.