Ahead some...just say...you can not do anything...because it "works."

For those who have works so far and not read.

It really works on the factory "filters".

In quotes, because regular snail

with great difficulty can be called filters.

with great difficulty can be called filters.

A piece of foam and a very narrow hole, reducing performance.

My friend, the compressor generally operates without filters, because they are usually broke and lazy to buy him.

The role of the filter in fact he performs a water-oil separator...scored wood dust in the trash.

I had originally planned to replace the filter for something a little more filtering.

Looked the prices of the "advanced" filter for compressors...the price of 10 dollars per piece I turned away...

Seeing the price of a regular car, round filter $1, it was decided to use exactly this type.

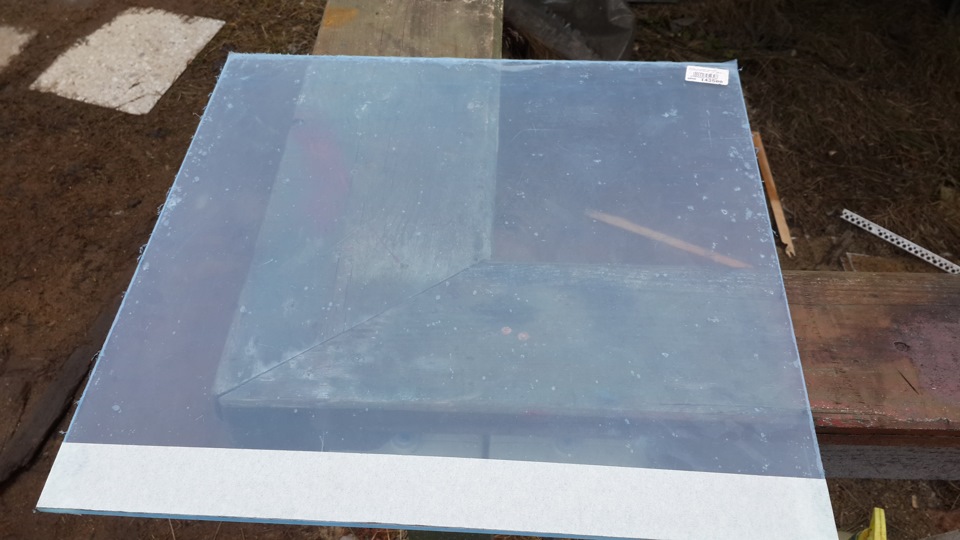

Yes, you can use a finished carburetor body and not to wrestle...but to go to market in search of such garbage, I didn't have the slightest desire...but it was a 5 mm sheet of Plex.

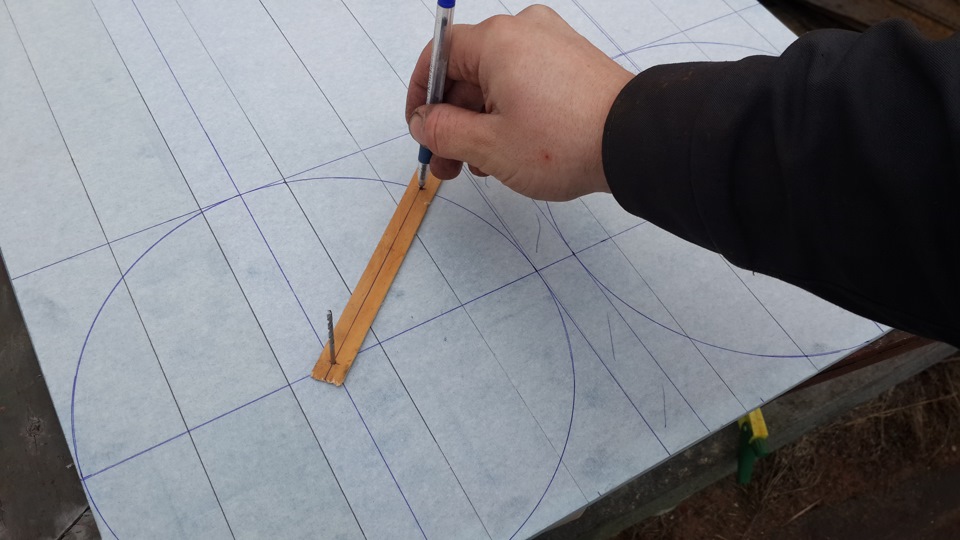

Spaced the whole thing in size.

Cut out with a jigsaw, kruglyashi, fraternal radius.

Then cut out the bagels and glued together.

Embedded bronze fittings for 1/2" and Profesional the groove under the skirt of the filter.

Secured on the stud in the casing head.

A cheap filter...

The air supply to the cylinders...the drain hose from the washing machine (until I use it...was perfect...thought will melt, but so far all hearty already 1.5 months)

The top cover is on the lamb...and transparent...you can see everything )

Everything works fine...the compressor obviously gets cleaner air, and freer breathing.

Where do without aesthetics.

You can even blue LEDs to illuminate the filter housing )

posts Andrew inspire, began to accumulate on the compressor.:) I want to turn the nut by an adult.Even before the oil service went to change.Many thanks.

Perhaps the idea I really liked!)) Still with the residence and garage it all came together!

So cleverly and aesthetically pleasing as much as no words! The fact that I from the date of purchase of the compressor is thought as the beginnings of these filters with a tiny orifice holes can theoretically pagerate flow suction! I in delight from idea to realization!))) Super!

No. It is hollow, that consists of copper, chicken wire mesh, it need a fleece attachment, personally I think.

Just if you think. I'm certainly not thinking to myself watery filter. a-a.d-cd.net/2ce647cs-480.jpg

How can I respect when in the workshop/garage and beautiful view!

Filter — separate "+"

Looks like an American motor muscle cars))) the Idea is cool, cheap and not at the expense of performance of the compressor

TopCTpeJloK

While the comments have not abolished the need to write something...Hmmm...Andrew, very cool and beautiful work!;)

Good and not expensive alteration

the air filter of the compressor.

normal filter instead of foam!

Examples of the darkness!))

1) www.drive2.ru/l/1737101/

2) www.drive2.ru/b/3029645/

3) www.drive2.ru/b/2518590/

4) www.drive2.ru/b/466096449105428772/

5) www.drive2.ru/c/474170712744001593/

6) www.drive2.ru/l/471883178802414336/

7) www.drive2.ru/b/1649052/

8) www.drive2.ru/c/2332068/

9) www.drive2.ru/c/2984942/

10) www.drive2.ru/c/460769865...age=0#a464362519268425863

11) a very interesting mount nashinskie

filters: www.drive2.ru/c/493501226671931862/

But 1 Vozduha 2 cylinder: www.drive2.ru/l/5414117/

While the comments have not abolished the need to write something...Hmmm...Andrew, very cool and beautiful work!;)

Those I say... I also Have the compressor running without the filter, type be sure to buy tomorrow or the day after... When every day you are a pneumatic tool, the will, not the will begin to notice that the container he fills all longer became=to be starting more often. As for me, it's your filter that is necessary. First, the filter element you can buy everywhere(and the day after tomorrow is not a channel))!1 In the second, your design looks cool)) I at least nagaraju yourself "something like" under common element. Thank you very much for post:)

And here is the result of my alterations: www.drive2.ru/l/7812834/ There at the end of the pictures) Made out of what was at hand. Case made of furniture Board (cut with a router, a groove is also made), pipes — polypropylene, removable design, the American. Thanks again for the idea!

Here it is the fish of my dreams, here it is! Damn, how in time! Yesterday I broke down the last of the regular filter. The first was the marriage initially, so already glued. That's the time to make a human being. I thought something similar to build, but here is a manual. Thank you very much for the useful information! I will do the same.

Don't know how you stuck the hose into the cylinders of the compressor?

I have almost the same filter

I bought immediately pushed them more parallon, but also think that the bandwidth has decreased

Great solution and execution :)

Good time of day might suggest the radius of the groove under the skirt of the filter(not possible now to measure) and the radius of the cover if possible.

I did a little easier — from plywood .

But when he huddled his ripped and the motor was covered, but that's another story )

Now choose the easiest compressor for nailer . But even they are slightly different the same filters . Conclusion La made : which filter to choose, and all of them only from the flies and stones . Either accept or comodality from Zhigulevsk .