The second stage, everything under the bottom - Toyota Sera, 1.5 L, 1990

After the first stage, one more task is required - at least so that the car can leave the garage on its own. This she cannot do so far. installed box with LSD. The starlet box with LSD has several snags, the photo from the previous stage shows such an "appendix" on the box, from the right-hand drive side, this is an additional "housing" in which the viscous clutch is located. Due to this, the box requires a shorter right-hand drive and its own rear cushion. Those. It can slightly leave the garage and drive back, due to LSD, on one driving wheel, but any further movement is closed. On the E-series of motors, there are three airbags - right, rear and front-left, attached to the spar. The rear bracket was missing on the box and was built from scratch.

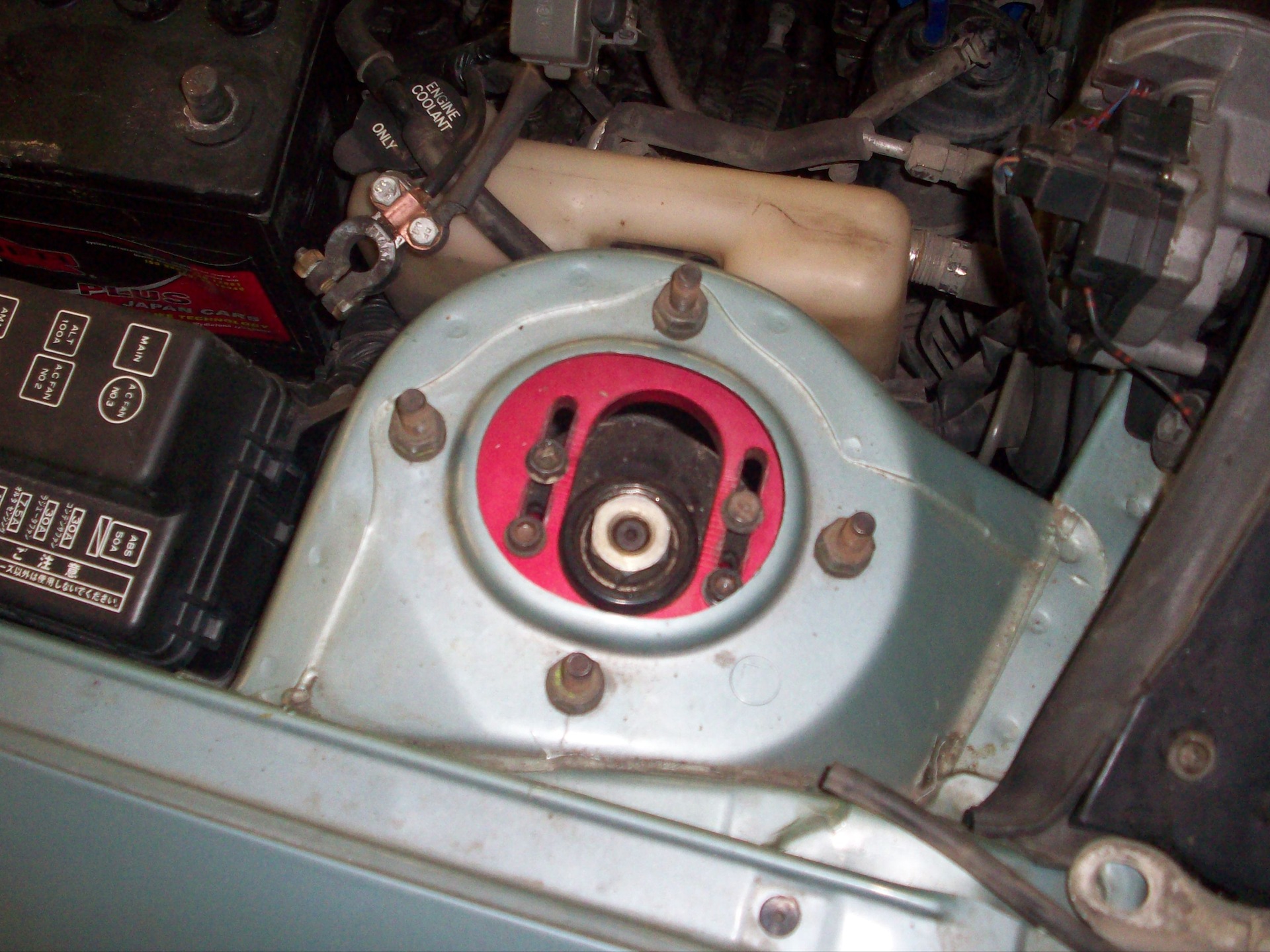

Even before the engine was installed, the attachment points for the right and left pillows were reinforced with "kerchiefs". Powerful motors break and break these places over time, proven by experience. In the photo, not Sera, but Tsinos, Sera's amplification is done in the same way, even a little more.

The right cushion was repressed with a new cartridge, an ordinary rubber one, on it there is practically only a torsional load. And the left and rear, as bearing the main load during acceleration, were made from the body of a regular pillow and polyurethane salent blocks. "Saylenblok" from "pillow" differ in the thickness of the damping part. The back cushion of standard sizes, even made of polyurethane, simply tears and crumbles with good boost pressure. The silentblock, due to its smaller thickness, turns out to be much more rigid and does not break. The negative effect is that more engine vibration is transmitted to the body. The amount of vibration at idle turned out to be the same as on the standard, but torn back pillow, which is unpleasant, but quite tolerable.

The engine now hangs securely, the next step is to manufacture a short drive under the LSD box. Finding such a used drive is practically impossible. This is the same, if not greater, deficit as a drive for a 4A-GZE box. The choice of possibilities is also limited by the fact that Sera's hubs are Starletovsky, their diameter is smaller than on the rest of the "Tercelovsky" family. On the Terzel / Korsa family, the hub diameter is the same as on the Corolla-shaped and Carino-shaped ones with A-motors. The left drive on Sere was already changed to a drive from Terzel, respectively, the hub was also replaced by the previous owners. And the right one remained "dear", Starletovsky. To save the budget, we decided to make a drive from the "native" one. Among the jeep drivers of trial drivers, there is a similar "tuning" - they simply weld the tripoid to the drive, because a powerful motor on the off-road can easily cut splines. We decided if jeeps drive like this - and we will try. They cut off a part of the drive and welded the tripoid pramo onto it, the boot, at the same time, ideally sat on the "local thickening" on the drive, as if it was necessary. It did not last long, but more on that later.

Then the "sports" suspension is installed. The suspension is removed from the ring Starlet, Buddy Club Racing Spec, has clearance adjustments, 16 positions for adjusting the stiffness of the shock absorbers. We set the clearance to the maximum, and the minimum stiffness, for now. However, here it was not without trifles - on the front struts there is no mount for the "stock" brake hose. These "ears" are cut from the native racks and welded onto the tuning kit.

The suspension itself was bought with the aim of participating in circuit races, because according to rumors, they planned to open a circuit for the ring in Novosibirsk in the summer. Unfortunately, due to the crisis, the track was never opened, as was the drag strip. The suspension is in excellent condition, but very, even extremely stiff. This is really a purely sports suspension, driving around the city on it is not comfortable. As I already wrote, I dreamed of putting the mayor in charge of the roads in the car and taking him along the central streets.

The supports of the front struts are also adjustable, but the camber is done only "for the ring", i.e. even the camber set to a minimum does not reach the "standard" one degree, the wheels are "house". At this point, Sulfur confidently moves in garages, drives out in the daytime and rumbles at idle.

The time has come for the next purchases - stainless steel pipes and bends for the exhaust system. Pipes 57 mm for the route are bought, three bends for them, a pipe of 100 mm for the final "can" of the muffler, blanks-bends for the exhaust manifold and corrugation for the "pants" are bought.

A fully straight-through line and a discharge can are manufactured in size.

Purchased wheels cannot be fastened with ordinary nuts. a very narrow "channel" for them. Nuts with an internal hexagon are bought, but also a minus - they are high and do not allow the covers to be put in place. Nevertheless, they are screwed on.

The second stage is over, the resulting semi-factory can drive on its own, if necessary. Those. this is the point where you can stop if you run out of money. I had a few more of them, so let's move on to the third stage - the engine compartment!

Yes, we made the mistake of cutting just near the edge.

For good reason, it was necessary to cut the drive and do the tube, as you described, we did the jet thrust that way.

But ... we decided that in this way we do not cut the drive at all. Those. we just "moved" the tripoid mount a little further, and cut off the excess. However, near the grenade mount the load is the most, and the drive was thinner than the left (the left drive and the fist were from a grater, thicker), in general, was enough to cut.

So as not to cut off the welded drive, they cook it in a special way (as the BUILDERS do), if you cook it straight, it will be cut off near the seam.

We grind both parts of the drive (at the junction we remove the chamfer), grind the tube (it is desirable to take the steel stronger) of such a size so that the parts of the drive are pressed into it (we cool the drive, heat the tube and connect it all), drill holes in the tube (2-4 on side), not going deep into the drive part (1-2mm), weld the holes.

something like this.