The third stage - truncated that under the hood - Toyota Sera, 1.5 L, 1990

Flanges for the turbine, inlet and outlet, are bought ready-made at Red Point, this is a plus for the "standard" - they are ready-made for it, the GT25 / 28 flange is common. A restrictor for oil is also bought there, because the turbine is ball bearing, and full oil pressure from the engine is contraindicated for it. Such a little "bzdyulina" but worth it, wow! For the "brand", to make a copy of this HKS at a normal factory, I think 500 rubles including profit. Now, by the way, GT Custom has mastered the "production" of similar restrictors from fairly inexpensive and affordable components. The flange for connecting to the engine is ordered from a "defense plant", where a manifold gasket is sent for a sample. On the supplying reinforced oil line, the savings are taken from the tuning of the Mazda RX-7 turbo, otherwise another 2.5 sput.

У Ð½Ð°Ñ Ð² городе маÑÑа заводов, и кое-где еÑÑ‚ÑŒ даже "уникальное" оборудование. С работой людей договоритÑÑ Ð¼Ð¾Ð¶Ð½Ð¾, и ÑовÑем конечно не по "ÑпонÑким" раÑценкам. Ðо… вÑе Ñти заводы — объекты режимные, и Ð´Ð»Ñ Ð·Ð°Ð½Ð¾Ñа/выноÑа любой железÑки — требуетÑÑ "БУМÐГÐ". РеÑли делать "официально", то… ну во-первых Ñ Ð¼Ð°Ð»ÐµÐ½ÑŒÐºÐ¾Ð¹ деталью в единÑтвенном ÑкземплÑре никто и ÑвÑзыватьÑÑ Ð½Ðµ будет, а во-вторых, поÑвлÑетÑÑ Ñтолько "поÑредников", что ценник получаетÑÑ ÑƒÐ¶Ðµ "европейÑкий". ПоÑтому незаменимый "реÑурÑ", Ñто "нужные люди", желательно, конечно, ÑƒÑ€Ð¾Ð²Ð½Ñ "начальника цеха", кому как повезёт Короче фланец нам неделю делали, благо заказали зарание. РебÑта вызывают знакомого аргонщика, и за 12 (!) чаÑов поÑвлÑетÑÑ Ñто произведение иÑкуÑÑтва, на который ушел целый баллон аргона ÐкÑпериментов было много…

The collector, after assembly, was given for "release" in the chamber, then the plane of the flanges was milled. Therefore, the engine flange is made so "thick", because after the release, it "leads" and you need to have enough "meat" for the subsequent milling of the plane. In the meantime, hoses are ordered to assemble the oil system. The oil cooler is slightly remade from the stock cooler from the Mazda RX-7. I ordered a spacer for an oil filter with a GREX thermostat (aka TRUST) for my filter size back in the winter from a Japanese Yahoo auction. Already when we went to buy aluminum pipes for the air system in the store, such a spacer was "in stock", and even cheaper than it cost me with delivery. I would have known the buy-in, as they say ... The thermostat housing from the 4E-FTE engine is installed on the head, with a branch for cooling the turbine with antifreeze, because it is ball-point and is not effectively cooled by oil.

The collector, ready for installation, is returned, the downpipe is assembled, the entire exhaust system is mounted. Sulfur is already humming in cocurrent flow, during gas circulation you can enjoy the view of the spinning compressor impeller.

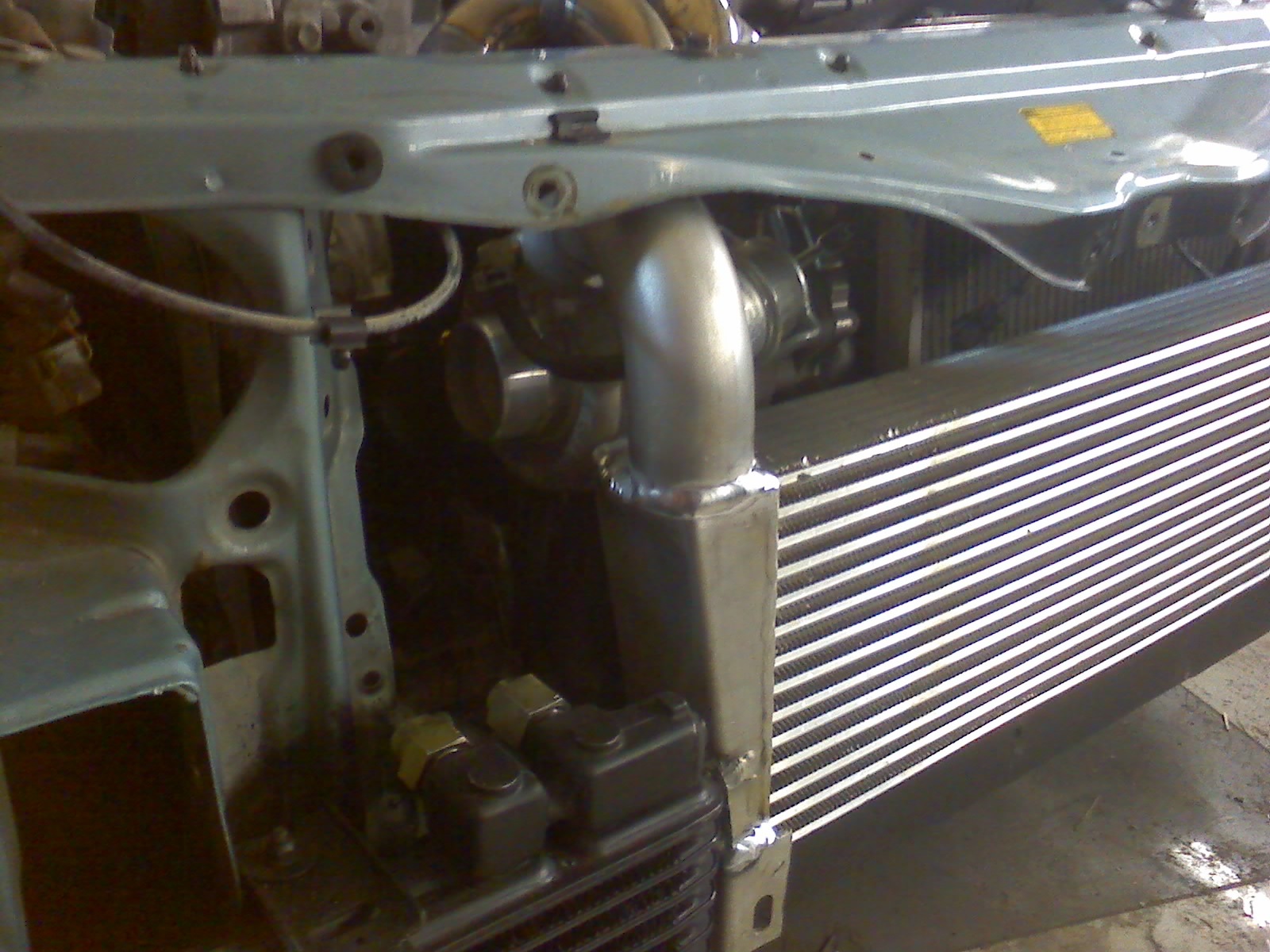

We start assembling the air system. Andrei sold his old intercooler, from which he "grew", even in the winter, and he also needed a new one. Once, having twirled a cooler from Valdai in his hands, he decided to buy one, and cut it in half to make two coolers for a small car. He ordered such a cooler from suppliers, but they still did not call or call ... And when we were driving for turbines, we went to a nearby store specializing in spare parts for buses. And there they saw IT. A huge intercooler for the Belarusian MAZ bus, for an almost "ridiculous" price, about 10 sput. Once again, "kicking" the suppliers, they admitted that they would not bring Valdai, went to take MAZ.

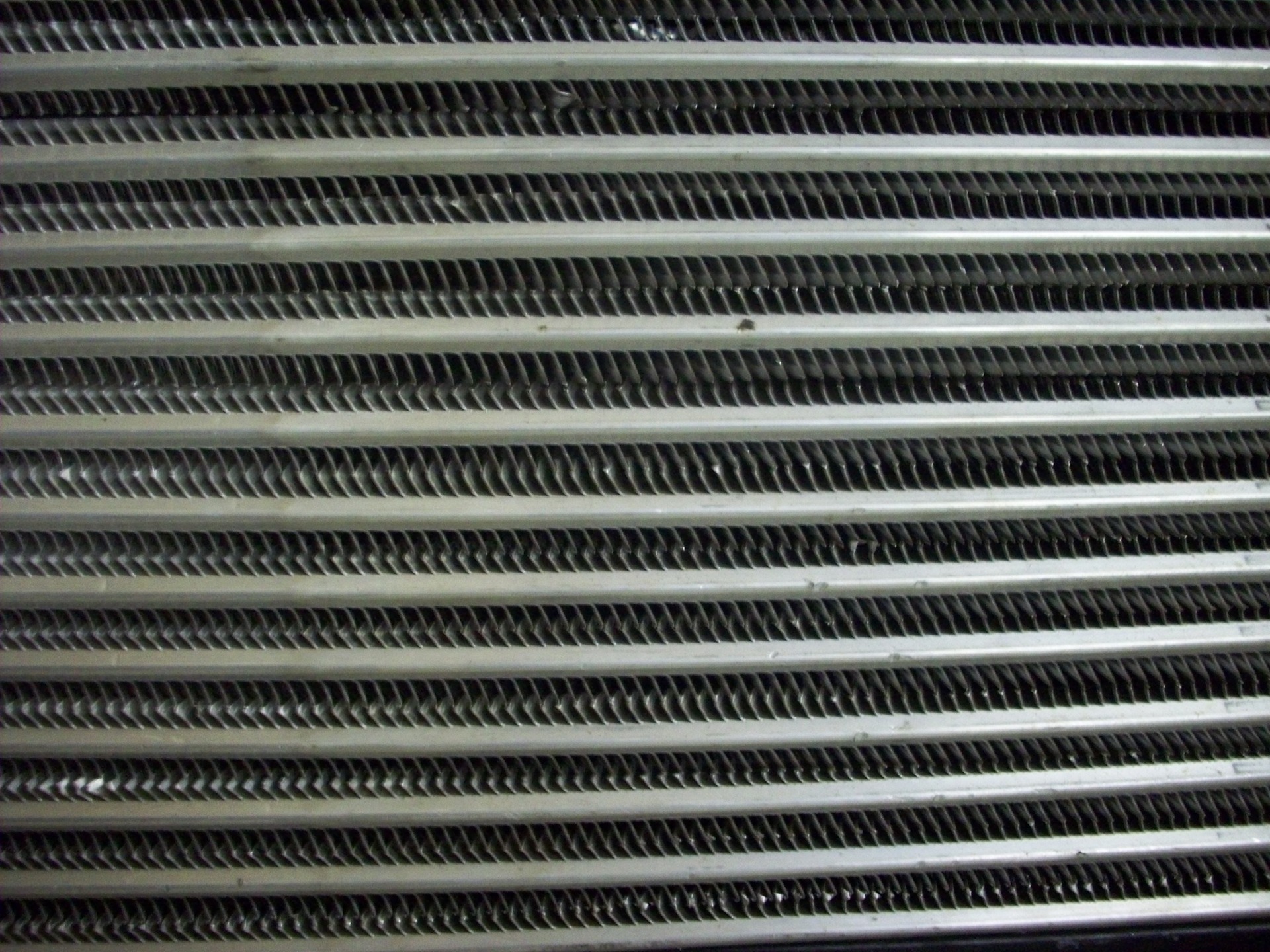

We twirled it in our hands, the pipes are "drawn", not cast, as in Chinese coolers. The cooling of the pipes deserves a special mention - this is not a welded "accordion" as on all previously encountered radiators, they are MILLED (more precisely, "cut" and bent) on the pipes themselves! Those. the cooling surface is at least twice as large as on the "brands". I think the Japanese can do that too, but it will cost - wow! The cooler has an OTK sticker with a test pressure of 3 bar. Take it! The seller, slightly Caucasian, was surprised that this intercooler has been on the counter for three years! It is "beautiful" and creates an entourage. You, apparently, do not take it for a bus? No! They explained why, and shook his head with Caucasian aplomb.

Later I understood why they had the cooler for 3 years. The thing is made very soundly, and will not crumble by itself. And she is in the bus at a height of more than 2 meters and slightly in depth. Those. to bend it in an accident, you need a minimum of KAMAZ or a similar "flat-faced" heavy truck. The cooler was "split in half", they began to try on the place and introduce pipes "my size" there, the bus one was "too big"

The cooler turned out - super! And in terms of performance, not every Supra has this. It was decided to lead the air ducts from above, so the shortest possible route is obtained, and, as a bonus, the possibility of damaging the silicone pipes from various "traffic phenomena" is excluded. Buy aluminum pipes, the main thing is "kultyga" from the intercooler to the throttle. Chinese is not available anywhere, so I overpay for Greddy. Alas, the end of the pipe with the inscription had to be cut off. The accumulator and the coolant expansion tank are moved a little "deep" in the engine compartment.

Vacuum hoses are replaced with silicone ones for beauty and reliability. A "Blow-Off" valve is being introduced into the "kultygu" pipe, a "bite" from the Mazda RX-7, as a temporary option, because in the presence of something inexpensive "Chinese" was not, and take the "branded" budget no longer allowed. Now the Chinese analogue of HKS SSQV has already been bought, a copy, disassembled, looked - ok. But at that time - from Mazda. Moreover, the valve from the Mazda is "bypass", i.e. excess pressure is vented back to the turbine inlet, so it is not completely "sealed" and sucks in air at the "vacuum". I go to the store, buy a small "zero" for ventilation of crankcase gases, which is spliced ​​with a spew with a rubber tube and superglue. Construction, as shown by operation,