How it's done (with pictures).

I write a lot with the question where to get such a wonderful button. Answer button it comes with controllera and not sold separately. But I will tell you how to get out of the situation and make the button yourself. So there you go!

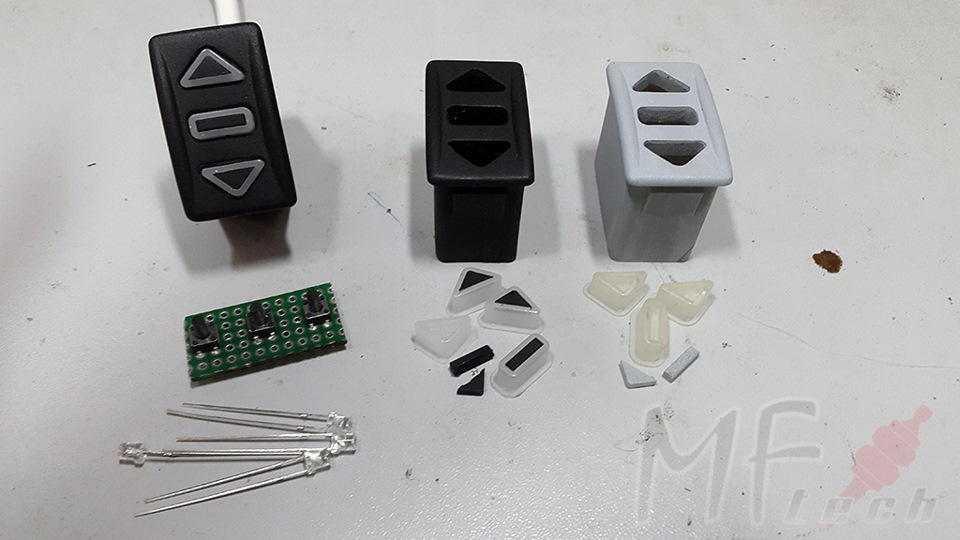

Initially I set myself the task to make a button that would fit well into the interior of the car was not terrible, with a well readable display and convenient. Based on these requirements it was decided to make the body and the buttons of plastic by the method of cold casting in silicone molds. To display well readable in daylight and not night blinded by the highlighted elements were made in the form of trims illuminated in bright LEDs. Well design is a matter of taste of course. I have this bad, so please don't be fooled. Although it turned out quite nice in my opinion.

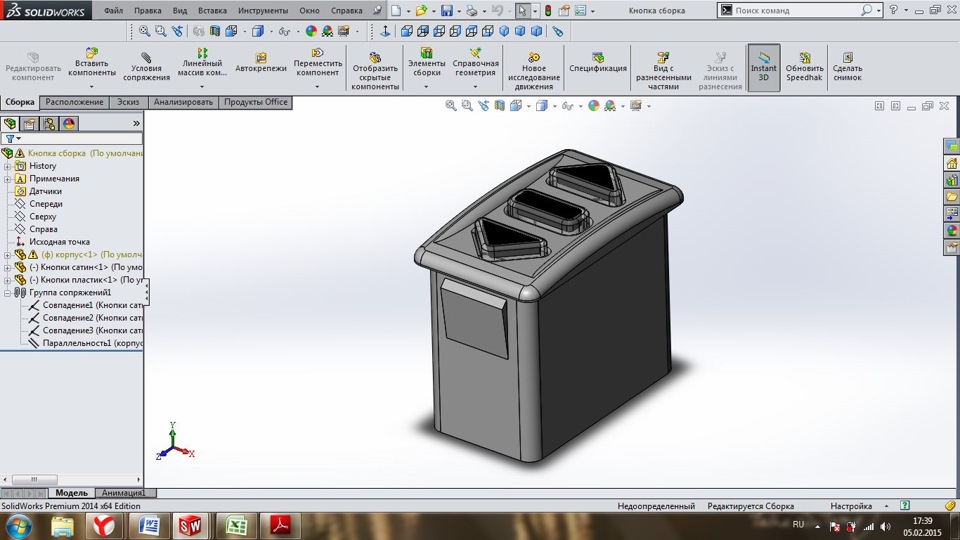

In General, for a start, your idea it is necessary to visualize. And so then, with this visualization could work the equipment. This fits any CAD. I personally use SolidWorks. Build a 3D model of a button, all the details are drawn separately of course, and then collected in Assembly-check the overall design and sent to a 3D printer. When you print a master model, it is desirable to use the SLS technology, as this technology allows to obtain the highest quality model, which means less post processing.

After fabrication of the master model, checking the compliance of the Assembly, gaps, fine-tuning the surface quality, the whole thing is a manufacture for producing the silicone matrices which would later be cast parts. This method is good because firstly the output is a normal plastic part, and secondly that it is possible to manufacture batch of identical parts in quantities up to 100 pieces in one matrix. Of course do not have to do it in production. The technology of molding plastic in the silicone is quite affordable and not very complicated for the average person. It would wish))

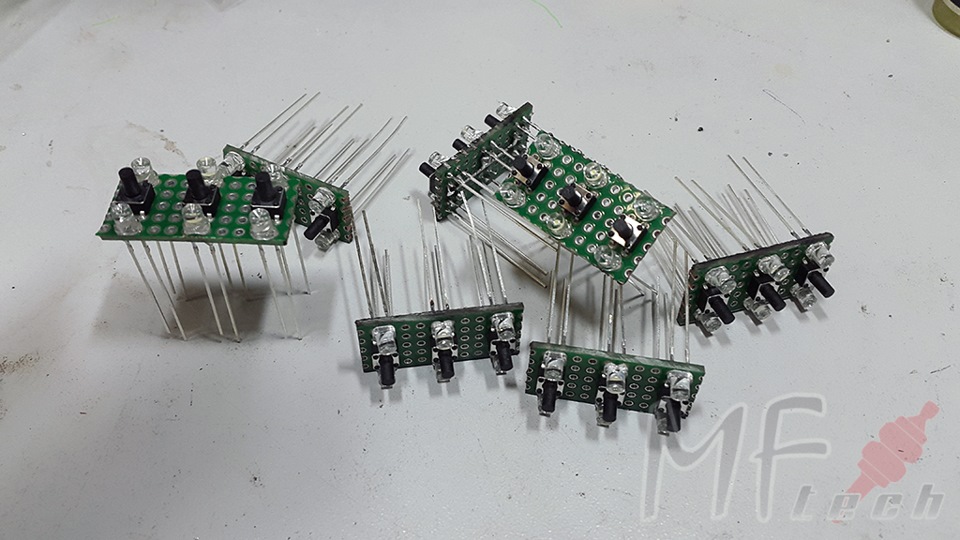

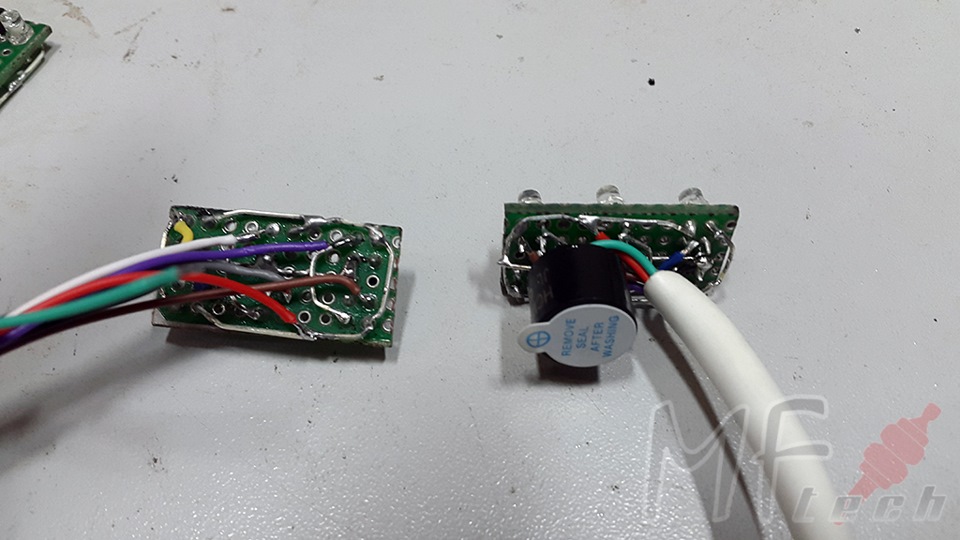

So, housing and buttons are made, proceed to making the filling. At the moment I use a regular circuit Board for the circuit assemblies. But one idea is to order a normal printed circuit Board. Probably for the next batch of buttons will do so.

Solder buttons, solder the LEDs.

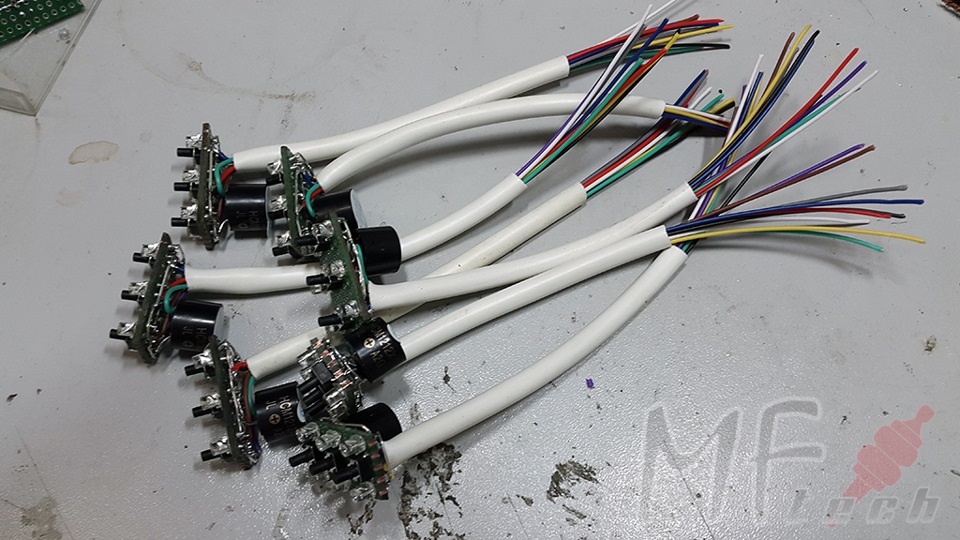

Doing the wiring.

Output wiring to connect. And solder the buzzer.

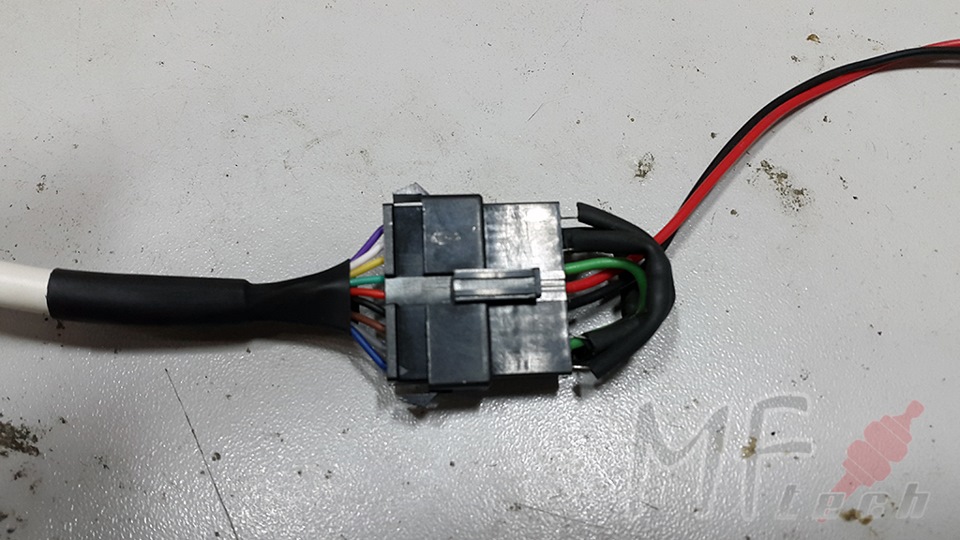

Crimp connector.

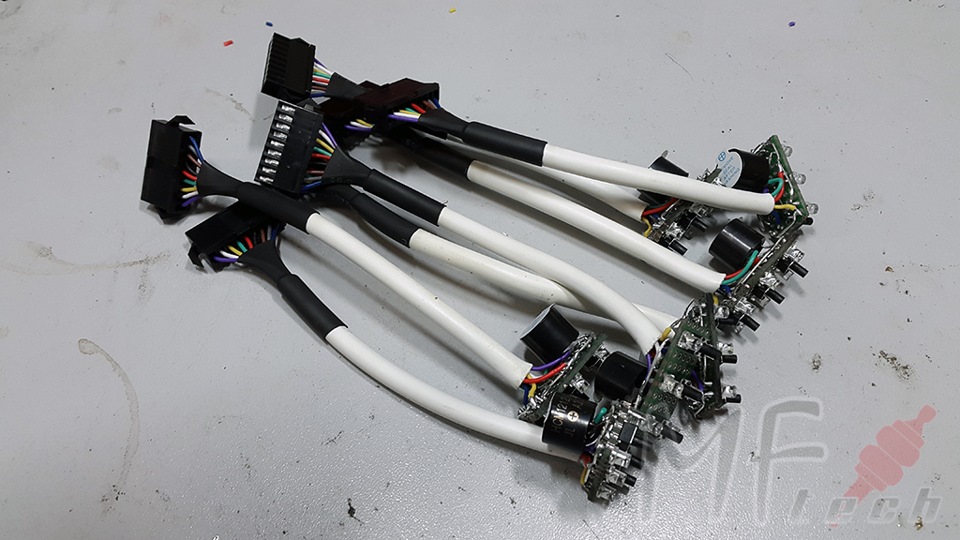

After this test the assembled circuit, fix mistakes, test again. For this I made a simple perechodnik, so every time the controller does not connect.

I did just a few buttons. This turned out to be a bunch))

Now it's time for final Assembly. Insert the buttons into the housing, insert a Board, fill with hot.

Here and ready our buttons)))

Glows so.

Our page on DRIVE2:

MF TECH control System air suspension. 1 verified review Watch prices, photos and contacts

MF TECH control System air suspension. 1 verified review Watch prices, photos and contacts

Without sensors still 18000. With the sensors while 32000 set. The price tag for the sensors and constantly growing, so sales do not know how to be.) I find it easier without sensors to give the kit, anyway most know where you can take them if that)) I on the sensors is still not earning anything. Just not in minus))

Of course. The user manual can be downloaded on my website under the controller.

In General, the number of channels is chosen in the menu the automatic calibration of the controller. After installing a new controller and switching it on, he would go in this menu and asked permission to otkalibrovani))

How and what steps to do and will be painted in the description of the controller?

Yes, it can. Then there is always the possibility to switch from 2 channel mode 4 channel.

And Your controller can work with only one axis. I have the rear axle is equipped cushion on the front yet, but plan to.

Pneumococci themselves live perfectly. What they will be then)) the question is limited solely to the drying of air by pumping the system. If the air is dry there is nothing to freeze and not be sticky. If moisture is not removed until the end you can freeze the valve. It's rather near-zero temperatures when the air is most humid. If a constant -30 moisture from the air wimobaiausy naturally)) but in the system in any case, need a good effective dehumidifier. I am currently engaged in establishing the production of silica gel desiccant to purge for regeneration of silica gel. Soon will be ready the first samples.

Yeah, already read that, what) do not know how the intention of taking lives at -30?)))

Don't know why this is, but cool! — just probably feel a whole plant))))

Read what what)) there is a question — pneuma in the frost for a long time?

VirusCar

wanted in the future, the front camera to put it where you can take a normal button?) to Parking or camera on it was written)

That's up to him try to ask elgr

Just do one button this method is probably senseless)) is Very expensive to come))

There is on the drive of the person who deals in button badges. right now, I'll try to find it.

wanted in the future, the front camera to put it where you can take a normal button?) to Parking or camera on it was written)

I agree. Just the evolution of buttons so happens)) Buttons of the first generation was done very differently and a pry bar was left of them. Will finish it and move on))

This size on a sheet of A4 will not come out little pieces, in total, faster than every unsolder... especially so)

I have this one)) But if I do the Board to order a party to the proceedings. To Tinker with etching no time and desire.

Manufacturer — class! Apart from the wild horror of soldering!((( There is a fee to print half an hour, if you have never experienced! SprintLayout, laser printer, iron and ferric chloride to help you! Well then another screwdriver with a drill ~0.5 and emery cloth)

Sorry)) this button came to light only because he could not find anything suitable for my problem. Had to do yourself.

I agree. The compass is of course compared to solid as the pelvis compared with the Maybach)) but it is widely used because we have a Russian product. Also tried poteryalsya, but after the solid has not gone at all)))

tosha3692

harder and generally solid? I'm still at uni once since 2002 has started and cannot get enough what a comfortable files)

for myself I know that in autocad the most inconvenient way of 3D drawing. how to use 3D Max, they are similar in management. Generally Solid rather simple program intuitive interface, very similar in management at Kompas, the night will understand.

Solid more flexible in my opinion. I first, it was all done I looked at autocad. Maybe I'm just accustomed to it.

harder and generally solid? I'm still at uni once since 2002 has started and cannot get enough what a comfortable files)

Yes you can and in autocad render. I just works better with autocad was not able to make friends)) solid for me, more comfortable)

Does not matter)) the main works. But I already vented about the manufacture of printed circuit boards. In principle inexpensive. You just need to sit down and wiring to do))

Alien2008

If anyone needs a key just "rocker" it is easier to buy ready-made.

For example

www.off-road-light.ru/ind...=com_virtuemart&Itemid=64

need to be a fan of buttons below it for 1344р to buy

If anyone needs a key just "rocker" it is easier to buy ready-made.

For example

www.off-road-light.ru/ind...=com_virtuemart&Itemid=64

This button is specifically for this controller.)) button controls the controller and he controls the air pump))

Well, how to say, the buttons to control the pneuma is full ))

OK, thanks for the advice, I sincerely wish you success — good things do.

The fact that this particular button is narrowly specialized and unique she is not)) if I was I wouldn't be fooled by manufacturer))

On your buttons I would suggest to buy a ready if you have and apply them to the image. In the beginning in comments gave link to a person who is engaged in it.

With regards to the production, this is not my profile)) engaged side so to speak because of the hopelessness of the situation))) I'm pneuma system, stand design and machine turnkey collect))

2000 — too much, in comparison with the cost of analogs, but until we leave this question aside.

I need the button functionality simpler: on/off and backlight. And a different picture. If there is interest, let the phone talk.

Yes, in principle, possible. But this method is good for batch production. To do a couple of buttons is not economically feasible. I did a batch of 20 pieces. The cost of one button turned around 2000. And that is without considering my time spent on all sorts of trips, procurement, design and Assembly of finished products))

The 3D printer was printed the master model, which is then a chance and it has been done in the matrix under the casting. The model was printed photopolymer.

System are different. If you count the fact that I usually put the equipment somewhere 150 including the stand. We need to see concrete machine iimet specific tasks. Then based on that pick the equipment and to consider))

I understand. everything will be removed. one ~the body from 21st remain. so I ask. how much.

I do not like you see everything else according to Hoyle. beautiful, worthy, and there seems small thingy and that's it! the shadow of the fence sprinkles... for the rest! ;) so... to help exclusively! :)

p.s. what is the budget set of all-all-all the equipment for installation in "body suspension" car based on the GAZ-21, so that the controllers themselves pneuma? about...

Possible. Just with these buttons turned a impromptu)) initially, they are entirely gathered at the knee)) the circuit Board is a relic of those times)) to be honest I never had the idea to bring the beauty inside the button. The main thing that worked. Did the outline of the PCB when I had the idea to put the photo sensor and dynamically change the brightness of the display for illumination. But not sensor fused))

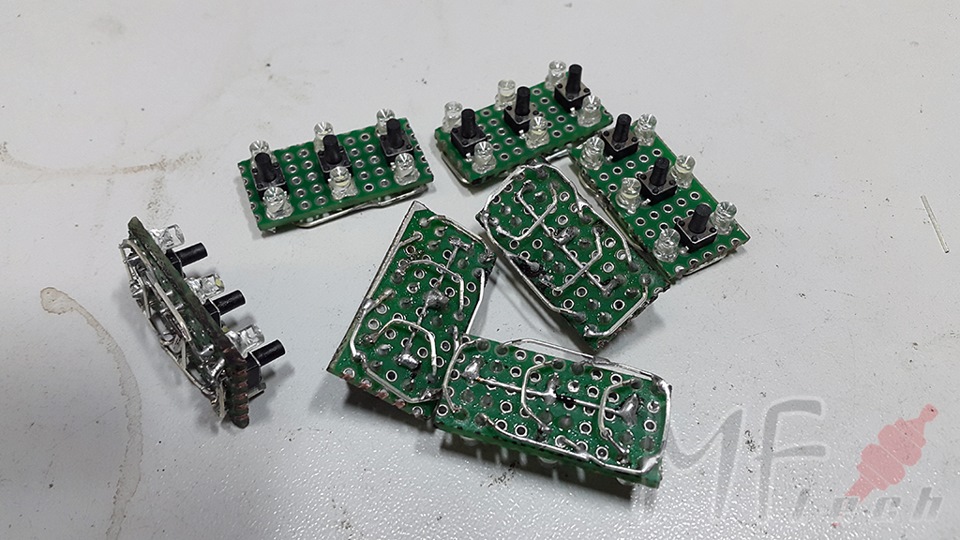

Vobshem I heard you, perfectionists. I solemnly promise to do PCB)))

Below already answered)) it doesn't matter. The scheme is reliable and works. The following party will order the PCB.

horror! is that porn on the reverse side of the Board? maybe a good time to NOT mounting to do?! once in such numbers!

short circuit

cool.

wishes\add-ons

where photos in the dark?

SMD LEDs should be.

wire too thick, and the plug would be more compact. Toki-around-zero...

Added a photo.

In the dark no pictures. It's difficult to photograph when the indication lights up. Now look, somewhere there were pictures installed in the car of a button.

SMD was not needed due to the nature of the build button. They can give illumination in the adjacent buttons))

Wire standards. 0.125 cross-section. Cable 10 lived with stranded wires is not so easy to find)) but the connectors are. Does not matter))

cool.

wishes\add-ons

where photos in the dark?

SMD LEDs should be.

wire too thick, and the plug would be more compact. Toki-around-zero...

Where is the proposal to use solid?)) I say that I for these purposes use it no more)) in any case, if people would choose it as your own it will solve the issue of licensing the product, as well as any other.

In our time of total tolerance, I would place the author of the little postremus imposing gesture to leave his master's shoulder with a proposal to use SolidWorks to model buttons in the native Lada ;) License for this software package street with 370 thousand wood, and for such proposals, accompanied by screenshots, it is possible and to sit down.

This is just friendly advice — precedents were. Should be more careful.

pavelkazaev

in nature, there is, with the cuts in the first place it take) the factory school, the button is really hot and melt, coming into disrepair. And then find it very hard) new expensive, used almost immediately to buy the guys living closer), but the option you suggested is not bad) only unused buttons do not have to crash unless where. And structurally, I think no one button it is not compatible.

Not warmed not melted, it is possible to unload the usual 4 pin relyuhi. work for 10 minutes

pavelkazaev

not argue with), then the relay will save her in the future)) but here the button is already to grab can not be over one and a half years))

quarrels have not read)

not argue with), then the relay will save her in the future)) but here the button is already to grab can not be over one and a half years))

Well I will say this. My version certainly is not bad. Just at the end of the button stand you as 10 regular))) is a solution for to save some dough, and make what is not and get absolutely nowhere, but very necessary)) factory school with overheating button is solved with the aid of elementary interchange circuit through the relay. I just don't mind sense to bother because thousand rubles)) buy new button, periodlate through the relay and forget about the problem forever))

in nature, there is, with the cuts in the first place it take) the factory school, the button is really hot and melt, coming into disrepair. And then find it very hard) new expensive, used almost immediately to buy the guys living closer), but the option you suggested is not bad) only unused buttons do not have to crash unless where. And structurally, I think no one button it is not compatible.

What is not in the nature of regular buttons on this machine? As an option to take some unused button and apply it pictogramme. At the beginning of the comments I gave a link to the person who can do it ;)

with such success easier with the pelvic squeeze in button)) cheap and cheerful, but not aesthetically pleasing(

Everything is in the hands of everyone. Offer the master model to whittle a knife out of a piece of wood, so as not to put))))

not sour work done) I would switch to be done in the same spirit, the deficit) on our machines )

Well done, well done, but the breadboard collective spoils, not really something you can not erase the beautiful shawls.

Che that you have a little exhaust from one form.

Like silicone 1000 casting stands (some claim 5,000). Moreover, the shape of the product you have is not that difficult.

Again. This is not the main profile of my work. If you do the same 1-2 buttons will be very expensive. So if you have the opportunity to purchase ready then it is better to buy))

Manufacturer just a button with 2 positions and with lighting. Buttons I would like to put on the glass lift. Would it be expensive?