Video: Machine for polishing discs. Homemade, simple and compact

Peace To You!

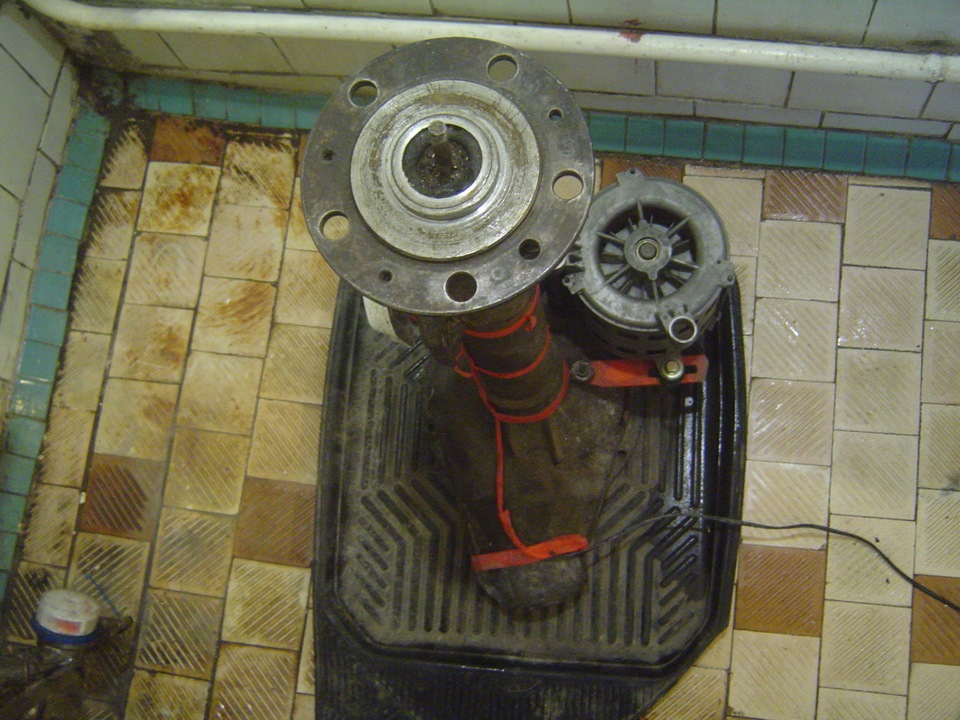

This machine is actually not mine, but a neighbor kartman1of my items (stockings axle GAZ-24 + motor) + some of my considerations here too, so publish in your blog

The construction is simple to a disgrace.

Half stocking-axle GAZ-24 (split) without diferenial. inside left the axle shaft in their native bearings

On top of the axle shaft machined under minimum TSO

And made a set of spacer rings for different TSO. The disk is pressed against cone

To operate the belt drive for the pulley welded

Motor 220V from the old machine machine Aspes (two-speed)

with native capacitor

Work process:

put the disc and clamp a cone

Include)

even with crooked drives design stand firmly (base heavy), but it would be better to put on a solid floor and put a rubber pad. Well, you can leg in the promotion of the ledge grip from the bottom to hold (to come)

The potential for tuning is to make the ground, put the flap over the engine (that would with a little rubbing) and connect the second. Better traction and lower speed, to clean off the paint to the base. Now the same store, but with a good clamp load sandpaper the speed drops.

Well, to come up with some guards in a circle, and it flies all in hand, if with the water to replace it) But the convenience of the location of the disc flies to the side, not in the face.

Thanks to this machine, assembled out of debris, speed the preparation of the disc grows significantly! Not to mention the opportunity to Polish the shelf)

Video review

The quality is not to kick, removed the differential from this bridge