Gearbox replacement - Toyota Corolla Levin, 1.6 liter, 1998

It was last summer :) The background is as follows - the jerking of the car began to strain me when switching to the engine braking mode - i.e. without squeezing the clutch, we release the gas, and at a certain moment of the drop in revolutions, we get several jolts that significantly disturb the smoothness of the ride. In the course of communication with competent people, we came to the conclusion that, most likely, the problem is in the differential. Plus periodically wedged switching 1st and 2nd gear. An unequivocal answer could only be given by the removal and disassembly of the checkpoint, which I could not dare to do because of my unwillingness to become a pedestrian for an indefinite time. And literally a month later, practically free of charge, a used box fell into my hands, a cursory examination of which allowed me to say that it would fit my car.

One sunny weekend, my box was removed (which I did not fail to participate in) and replaced the existing one. She, however, was not without jambs, but as a temporary option - it suited me. I didn’t know then that it would take about two months to drive it.

It turned out that it was completely impossible to find synchronizers and differential gears in my city. The maximum that is - contract checkpoints, and even then all the machines. I had to make an order to Japan and wait three weeks. And then another three weeks, tk. the first time by mistake on the diagram I was shown synchronizers for 3rd and 4th gear, instead of 1st and 2nd.

Nevertheless, the hour came when they returned my gearbox - and the happy moment of its installation came. I decided to do it myself in the garage :)

The first thing I did was jack up the car - since my hole is not deep, I had to lift it as high as possible. This procedure took about 30 minutes - because apart from the auto-jack and boards for the stands, nothing was found.

He took off the front wheels:

He unscrewed the drives from the side of the hubs and removed them:

When I pulled the drive out of the box - I realized that I had stepped - it was necessary to first drain the oil, but it was too late! It merged, of course, but to the bottom of the pit and partially to me (the photo shows that the box is covered in oil). And it turned out to be so smelly - there is still a smell in the pit.

This is left-hand drive - the boot on the inner "grenade" burst due to minor damage during the previous swap. I stock up on a new one in advance :)

This very "grenade" is installed here:

And this is the mount on the box body for the front engine mount:

But so handicraft :) we hung up the engine to remove the pillows:

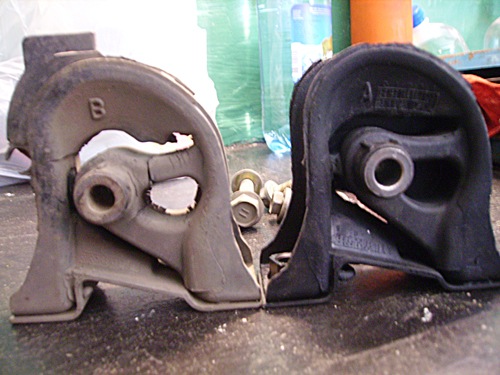

This is actually the front airbag - the old one is torn, which caused a decent vibration at low revs. Nearby is a new pillow - just from the store :) This piece of rubber is not cheap (about two rubles)!

This is the right hub, and in the background a freshly refurbished gearbox! :)

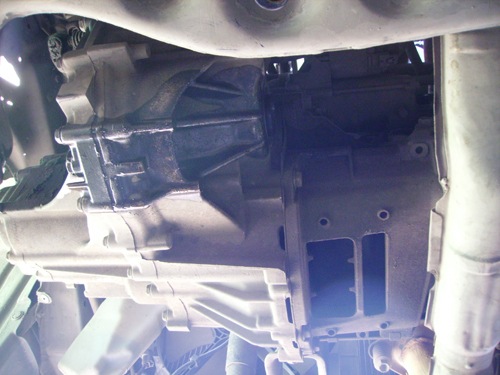

Box - bottom view:

And so we took it off! I began to disassemble at about 10 am, and we removed the box at 4 pm. We filmed together - I would not have pulled it off into one helmet - 40-50 kilograms after all!

She is the hero of the occasion:

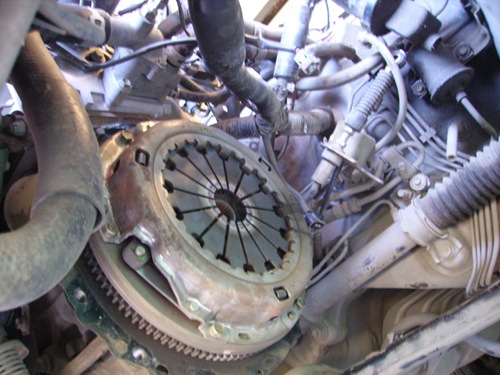

This is a bottom view of the basket, clutch and flywheel.

Then they safely delivered the repaired gearbox and all the other removed units and parts.

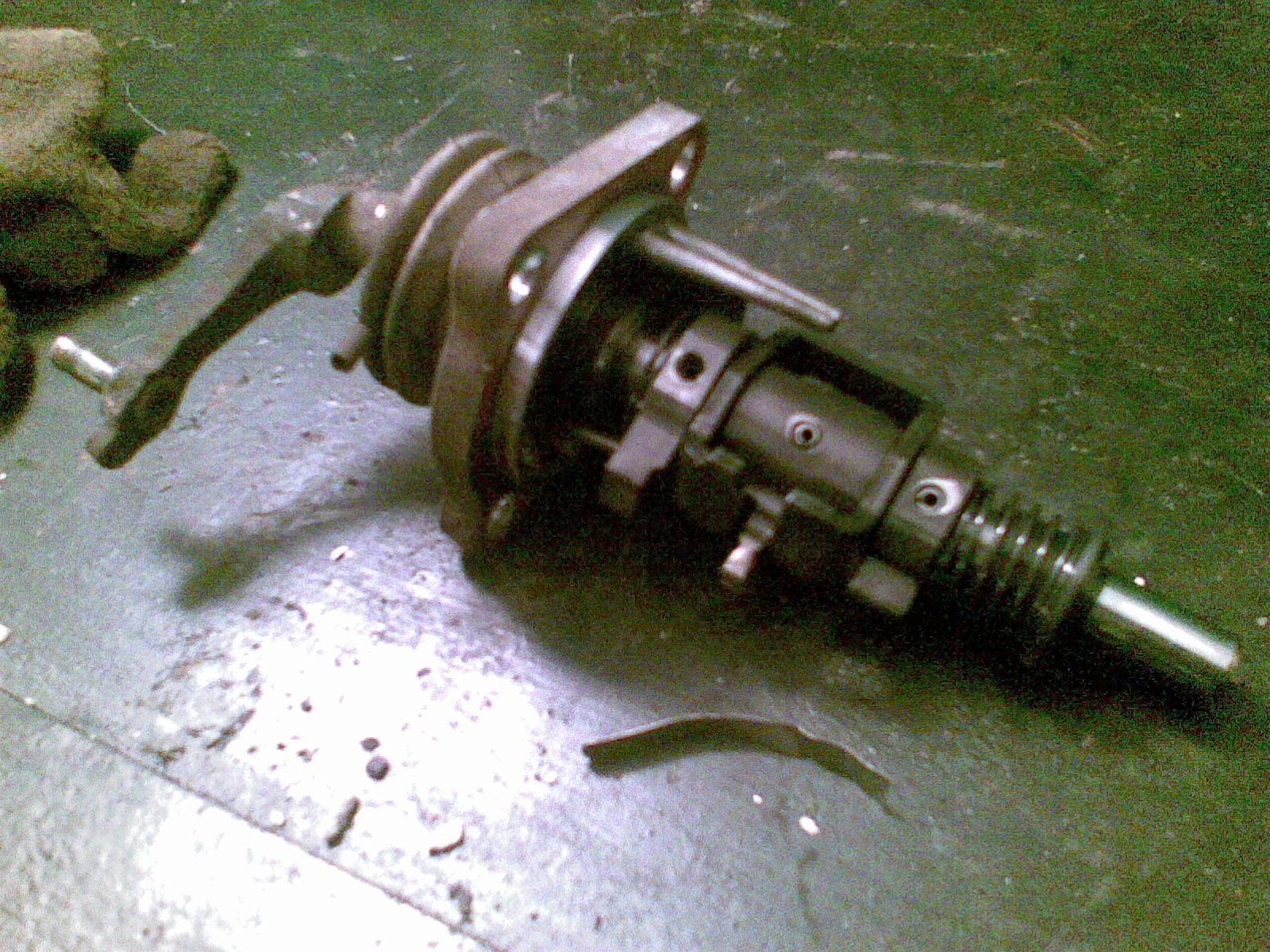

A week-long test drive showed that the problem with the differential was solved, but with the gear change it only got worse! As a result, it turned out that there is one more problematic unit, namely the "gear lever shaft" (if my memory serves me right):

Replaced it with one removed from another box. And everything became, if not excellent, then quite acceptable. And the main thing in this story is that the whole procedure done brought me one more step closer to the engine swap :)