In Russia do car tires

If you ask me what I love the most, I would say the production! There is nothing to a greater extent embody the greatness of human achievement than the production process. The transformation of minerals in instruments of production. Processing of secondary product in the primary. It also is a demonstration of the real achievements of the human race – and not a round table on the problems or start up a smoothie in coworking. Today I will tell you about how produce tires at the plant of the Finnish company Nokian Tyres at the plant in Vsevolozhsk near St. Petersburg.

Industrial zone of Vsevolozhsk – the combination of a large number of enterprises with certain tax benefits. Chemical plants, Assembly production of different car brands... In the same buildings, black and gray-green plant looks like Nokian hung with garlands, a Christmas tree, suddenly encountered in the depths of the taiga.

The first thing that greets me after the entrance – elegant, spacious dining room, where you will be the envy of any Moscow business center. Lunch – salad with chicken, soup with meat, macaroni with mincemeat, compote and tea costs me... in 77 rubles. This is not the only benefit, which employees receive company constructed two phases of a private residential complex in the Swedish project. Apartments in it, on concessional terms, stood the real line. Today, Hakkapeliitta Village 340 lives of the families of the employees of the company, as the property offers 2 private kindergartens.

For starters I will say the most important thing. Nokian plant in Russia is two times larger and at times more productive than the Finnish. In compliance with universal quality standards, manufacture in the town of Nokia is able to produce up to six million tires per year and the capacity of plant in Vsevolozhsk – 15.5 million tyres per year and will soon reach 17 million tires. Production runs around the clock in four shifts, it involves 1150 employees twice a year and passing a recertification.

The first stage of the production of tires – "mixed". On two floors of the production building is located 12 production lines for rubber compounds. Eight lines from primary raw materials to produce base mix, four final.

The base mixture is produced from the natural rubber supply from Southeast Asia, synthetic rubber (it on both the production site of Nokian Tyres mainly supply Russian plants), carbon black, silica, and various additives – activators, inhibitors, plasticizers, adhesive agents.

Full sizeBefore loading in the mixer, the rubber compound is cut into strips. Bottom left — natural rubber, right — synthetic

Full sizeBefore loading in the mixer, the rubber compound is cut into strips. Bottom left — natural rubber, right — synthetic

The need to use synthetic rubber due to the nonideal characteristics of natural rubber. Which, moreover, requires special storage conditions – the plant it comes in frozen, then in a special... warms the sauna.

Raw material is loaded into special machines – extruders according to the given recipe for a particular type of mixture (a total of more than 30 types, for different components and models of tires).

Output – the so-called basic mixture. It enters the extruder in the form of wide ribbons, it adds additional chemicals, then the output is in the form of black tape, the final mixture suitable for the manufacture of components tires. Certified according to quality standard ISO 14001 manufacturing not applicable harmful, so it does have a negative impact on the health of employees.

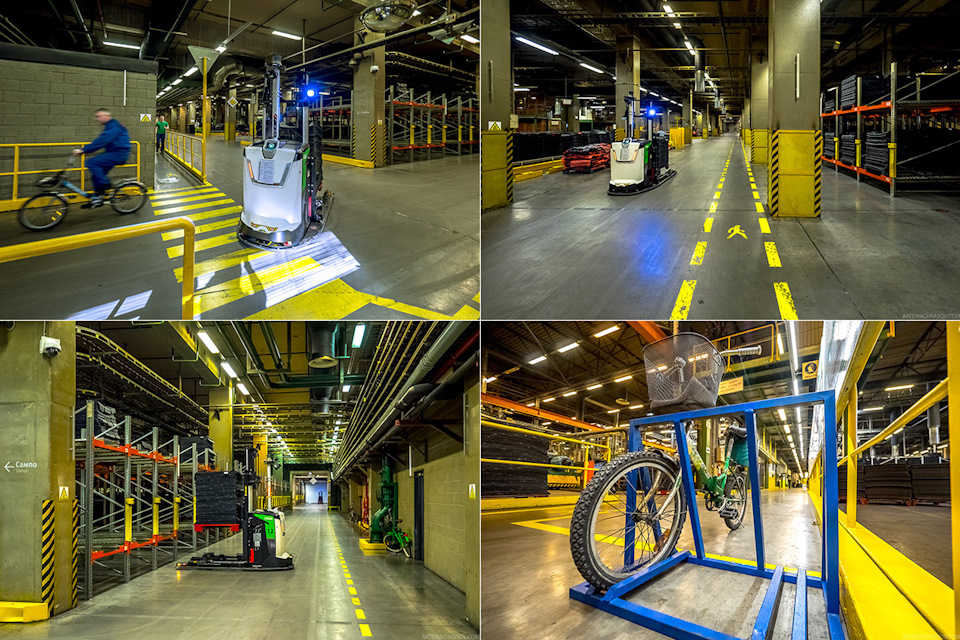

It is noteworthy that the transport of compounds through the plant carrying out... robots! Auto loaders are able to find the necessary shelving yourself, and stop automatically in case of detecting obstacles in its path. On the floor of the factory buildings have special markings that cannot be crossed Hiking staff.

Full sizeBesides the robot, the plant uses bicycles. Otherwise, walk from lunch to the place of work can take a half hour...

Full sizeBesides the robot, the plant uses bicycles. Otherwise, walk from lunch to the place of work can take a half hour...

In case of unplanned stops, the camera on the robot to record video, which will help to identify the perpetrator of the violation of the production cycle. It is clear that nothing good is not waiting for it – security at the plant in Vsevolozhsk seriously.

The proof of this is the free muffins in the canteen, issued by the Department of labor for achieving the "140 days without injury". Injuries at the plant even include contusions and sprains of the lower leg of the women in the office related to the use of heels. According to the information on the stands, fractures in the production almost did not happen, and serious injuries was not even once since the launch of the plant in 2005. Remarkably, mainly port statistics office staff, and more – employee podvorachivaetsya feet from the heels on the stairs. Therefore, the length of the heels at the enterprise are strictly regulated, and to enter with them on the production itself, and even prohibited. But let's not deviate from the topic:)

Full sizeAt the factory at the entrance handing out free earplugs, has a medical office and a sports hall with gym and sauna. In the shops there is even a Smoking room, but for a few hours at the factory I didn't see anyone.

Full sizeAt the factory at the entrance handing out free earplugs, has a medical office and a sports hall with gym and sauna. In the shops there is even a Smoking room, but for a few hours at the factory I didn't see anyone.

After producing the final mixture is made by laboratory testing of each belt of the mixture.

net/431f391s-1920.jpg class=c-lightbox-anchor c-pic-zoom data-action=lightbox.zoom data-size=1200,800 rel=noopener target=_blank> Full size

Full size

Checked its composition and physical properties (the spectacular test stretch).

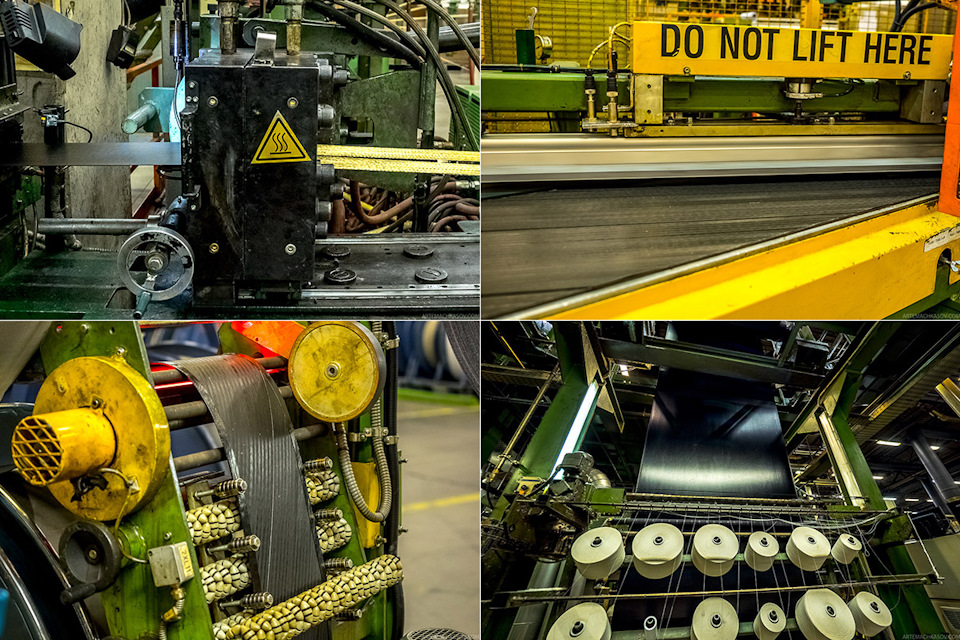

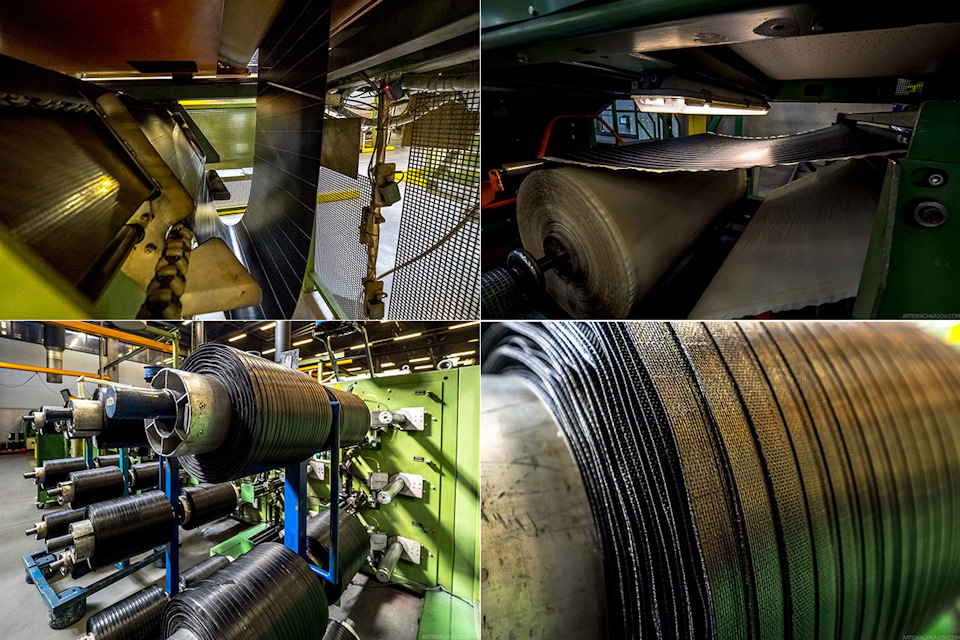

Inconsistent quality standards of the mixture are recycled. After all mixtures tested, the next stage — the manufacture of components tires. Doing this on the two types of lines, long and short. Long line — universal, they are after the appropriate reconfiguration can be used to produce the various components of the tyre such as tread band, sidewalls, germoloid.

Tread unit works as follows — in the extruder (mixer) is fed four types of rubber mixtures, which are mixed as desired, shaping the future protector with preformer and profile bars. Since different tires and different compounds, and the profile, each of the protective tape is appropriately labeled (color stripe alphanumeric code).

After that, the protective tape is added to a cushioning layer. The tape is cooled with water and wound on a huge spool (tape length: up to 90 m).

On a similar principle to long lines and other components are made – hermosas and sides.

Short lines are less versatile — they make specific components. Side fender, steel belt, nylon bandage and rubber-coated textile cord.

The first thing rubberized textile fabric enters the sewing machine. Cord is cut with different widths and angles across the warp threads, connected and wound into coils. It is noteworthy that work with these units mostly women — there is very important care and diligence.

The other textile fabric is fed to another machine of slitter, where it is cut into strips with a width of 180 mm. After the tape is sent in the refrigerator to prevent them from sticking together. There they are till the next phase, the slicing into strips.

Rolls of tape come on minisiter, which cuts them into 10-millimeter strips JLB, which subsequently act as a nylon brace bus, responsible for the index future speed of the tire.

On the production line of bead ring is a special machine obrushivaet steel wire and wound it on the drums (from 13 to 44 turns). The task of the bead wire tightly to hold the tire to the rim of the wheel

On the next line is wrapped filler cord, also called the apex. The rubber compound is formed through the extruder and is attached to the onboard ring.

The following machine is weaving steel cord and its subsequent abrazivnie. Interestingly, after that cord is cut diagonally (at an angle of 25 degrees), then glued together into a single tape and is wound on the coil.

Full sizethe manufacturing Process of steel cord and rubber-coating. The last photo is seen as a material for the sidewall of the tire is stitched a white cotton thread. In the process of vulcanization of the tire the thread is burned, and through these holes comes out hot air. Exactly what get thin whiskers on the sidewalls.

Full sizethe manufacturing Process of steel cord and rubber-coating. The last photo is seen as a material for the sidewall of the tire is stitched a white cotton thread. In the process of vulcanization of the tire the thread is burned, and through these holes comes out hot air. Exactly what get thin whiskers on the sidewalls.

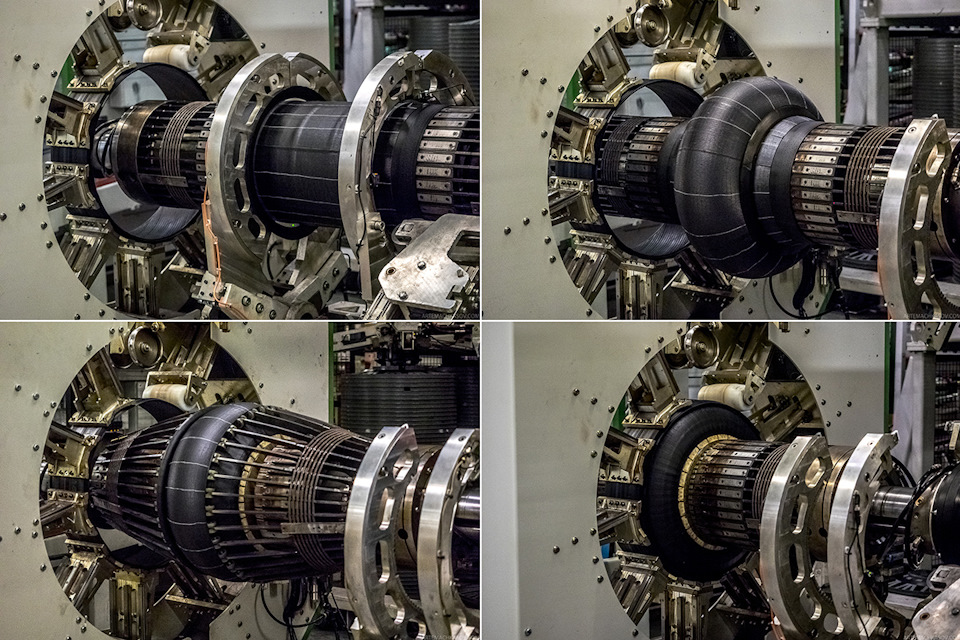

After all components are ready, they go to the Assembly shop. The plant employs kinosborniki three different generations – 6 German machines Krupp, as well as 45 of the Dutch VMI machines 20 machines of the latest generation VMI MAXX. The key difference of the new machines — fully automated build process of the tire that does not require human intervention.

jpg width=960 height=320 itemprop=contentUrl>Full size

On the first reel on Ermolai, pre-connected to the sidewalls, wrap-rubberized textile cord, put on the side fenders, in the tire the pressure, and sides turned inside out.

At the same time on the second reel connected to each other two layers of steel belt on top of them wrap-JLB tape (nylon band) and the protective layer. It turns out Bracero-protective package. By using an automatic transfer it is connected with the second part of the bus. The rollers rolled down one part to another. It turns out the so-called “green tire”, completely ready to the final stage of production — vulcanization.

Video Assembly tyres:

With the help of automatic transportation lines, green tire into the shop vulcanization. The automation reads the label and the “green bus” hits the drum with the desired mold. Inside it is inserted into the so-called diaphragm — durable rubber bag which is inflated from the inside with hot steam under high pressure. Outside on the tire on all sides presses the mold, which causes the tread pattern and the markings on the sidewalls. Bake one bus goes from 8 to 12 minutes depending on model and size.

After baking, the tire is cooled on rollers and is fed to a conveyor.

Further it is not the way to the warehouse, and the stage control. First, each tire gets on the visual inspection. Then employ the most experienced plant employees, able to distinguish summer tires from winter smell, and eye, and touch to recognize over 130 of possible defects. The proficiency of these professionals, supported by special inspections, when they are given a bus with specific defects (which do not speak), and asked to define marriage. If the bus for one reason or another rejected, it is sent to the engineer. After confirmation of defect, the tire cut in half (to anyone not occur to her to use), and direct Deposit. In one day the supervisor checks over 10,000 tires.

Full sizeVisual inspection of the tire. The weigh-in. Marking. Warehouse of product rejections — please note, all tyres are cut in half. All the scraps are processed into various rubber products such as car mats, speed bumps, carpet for children's playgrounds. Thus, the plant does not produce waste.

Full sizeVisual inspection of the tire. The weigh-in. Marking. Warehouse of product rejections — please note, all tyres are cut in half. All the scraps are processed into various rubber products such as car mats, speed bumps, carpet for children's playgrounds. Thus, the plant does not produce waste.

The tire defect comes in the line of automatic testing, where a special machine to check that they meet the required weight, no taper, beating, etc. this tire is fixed onto a special drum, it is fed pressure and simulated various operating conditions. After all tests have passed on their tires marked and they are sent to the warehouse.

Studded tires before you get to the warehouse, find themselves in the shop studding. Automatic machines according to their program shipout tire yourself by reading the holes for the spikes. The plant used two types of machines — conventional, which you see in the photo and which are used, among other plants, and the latest that the company holds in total secret and used for studing of their flagship models.

At the plant in Vsevolozhsk make tires that are exported in more than 40 countries, including Central Europe, Scandinavia and North America. A giant warehouse to get around only for a few hours. They keep about one and a half million tires.

The range is completely replaced in less than a month, as the plant has the ability to work stock, and in accordance with the current needs of the market. Made the only tires that are ordered by distributors. Doing here and the hot new product from Nokian Tyres — off-road tires Nokian RockProof. But the giant industrial tyres designed for working in mines and quarries special equipment are manufactured in a Finnish factory of the concern.

Factory visit Nokian Tyres is a real delight. Created the jobs, people hold on to this job (most of the staff has been working for over 7 years and go nowhere plans), the Company is very modern, nice and clean. Last I appreciated, when in the midst of shooting decided to remove some of the machines by brazilianu from the lower angle, which had to kneel. About the fact that I'm wearing new jeans, I forgot... What was my surprise, my knees were absolutely clean...

Ask questions on production or products Nokian Tyres — the answers I will draw the employees of the plant!

Like this post? Then subscribe to my blog!

ZanudaBatkovich

And I'm not noticed! The in was model Hakkapelitta 7 and 8 domestic production. Runs on them was 35-40t.km for two seasons and the loss of spikes was minimal. Now ride 9-ku maid in Russia

Is the mileage? You can tell the car under the Windows missing, and all of season bespontovoy can perekantovatsya.

I had a Finnish 5-I, 8 seasons for each wheel -2-3 thorn. And 7-from the third year, fingers are not enough

And I'm not noticed! The in was model Hakkapelitta 7 and 8 domestic production. Runs on them was 35-40t.km for two seasons and the loss of spikes was minimal. Now ride 9-ku maid in Russia

Xvicho

Took in December 8ku drove 5000km, the first 500km as a pensioner, without sudden acceleration and braking, but in spite of this, some of the spikes are already out. To be honest the rubber cost 10p per beaulon expected more quality.

Because we do steel. It was noticed that if the production — Russia, half studs fucking fly. In Finnish, this was not. He bowled 8 seasons in the Finnish 5th hack

The worst thing is that not only the wheels but the foreign cars Made in the rush, he paid when Octavia Nizhny Novgorod tried to register in the Czech Republic. I think that buying a European brand — fuck you — you buy the shit for third world countries.

Read a lot, heard plenty of reviews etc Bought nordman suv made in Russia. It's not a tire - it is shit. Drove 500 km type run, carefully so, the seats are broken spikes, the spikes began to fade. On the lid there are extra castings. Better Korean bought. Everything is made on the CIS goes into the category of consumer goods. And the article is Yes, beautiful, expensive...

article review cool. I prefer other brands. not the point just like the people working there. the work is monotonous a certain job makes a particular person not as we Bob and mechanic and electrician and Director in one person. just from monotonous repetitive work if the brain is they will spoil. I love the variety in the work.even working as an electrician at the plant had a choice in the change on tenure or on submenus.chose for submenus in all shifts as home I liked. if it wasn't for the war.

Overcast-day

Similarly with batteries. Just bought a few expensive — for a couple of years missing.

Now the price and brand is not a guarantee of quality.

With Akuma all the way!

Only our started yato to do — you can not buy it anymore

Well, just a piece of Finland in the middle of Russia. Why are the tires shit with this plant, it is not clear) the damn Place is probably like the joke about AVTOVAZ.

taxistsolik

The point is that the Finnish Hakka, much better than the Russian Hakka.

Confirm.

Finnish for very long runs, I did not wait that the time has come to change it, so two cars were sold on the Finnish Hakka.

Friends of the St. Petersburg 50/50 as lucky.

But we have a very expensive Finnish was moved to the Japanese Toyo.

Let stand for more than 10 years as Finnish.

V3xin3

Not convincing

People who traveled on the Finnish and Russian to convince Nokian makes no sense. I buy camu is better than the brand which is made in Russia. Was the experience of owning the rubber Finnish and the Russian Nokian. The Russian threw the still half tread. Began the separation of rubber and cord destruction.

What I want to say it's been a long time I like that I went on the Hakka 2 ( Finnish)and a very long time ( order of 80000 km) was the moment I got it for half the summer was gone, and I took it b/a as the spikes fell out but I did not understand I had to break up with her because, come on, hump. In the cabin when buying a Rio sell me Nokia 5 made in Rus, that's a miracle, what the hell. Maybe it's the Communists lizh to do to unsubscribe.no I'm not against the Russian, but risino thank you.

Funny turns. Finns Hayat the plant, and praised the rubber "tehty Pietarissa"(made in St. Petersburg).

He rolled only frictiony Hakka, always buy in Finland (so cheaper) vsevolojsky and there is no problem.

AVTX

Quote: "one day the supervisor checks over 10,000 tires". End quote.

Quote: "Here is staffed by the most experienced plant employees, able to distinguish summer tires from winter smell, and eye, and touch to recognize over 130 of possible defects." End quote.

So, we have:

1. One of the most experienced employees (controller);

2. 10,000 tires per day (which day, it is not clear, but let it be 12-hour working day);

3. 130 possible defects.

This means that one controller will check:

833 bus per hour;

14 tires per minute.

Thus, for 4.3 seconds, the controller verifies the absence/presence of one or more of the 130-and possible defects.

Again. Single supervisor of the 130 possible defects and the whole 4.3 seconds (assuming 12-hour day).

In "the Guinness Book of records" the application has not yet been filed?

Handsome, CHECKMATE Nokian, CHECKMATE!

I don't know what write here. Skated personally 4,5,7 the Hakka. In the last 7 tiesdell sideways on asphalt 6 winters with a total mileage of 60 thousand km away. the thorns were the first to fall 5 winter, and it is because no longer take care of resu and properties began to lose

The Hakka r2 Russian, barely out of 3 winters. by the end of season 3 almost all snowflakes obliterated — stopped being winter, and humps appeared, I thought the wheel whirred three different imprint in one voice sentenced "magic wheel" throw them the noise will go away.

Polyethylene terephthalate — pet, perhaps . PET easier Kazanorgsintez primary to buy.

You're wrong, I personally did a report from the factory where the secondary make bottles for drinking water and soda. PM for Coca Cola they make. The technology is called bottle-to-bottle. If interested I will give a reference

artemspec

I've had something else in mind, e.g. recycling dirty PET garbage plastic in the food;)

In the food — no . From the secondary pet for other purposes .

Okay, let's be honest . I am 8 years in this field — polyethylene is a pet, pet — pet bottles are made from pet. The recycling of pet, especially if then used in food packaging ( and not for getting your jackets and pillows ) — a very expensive ( and profitable then ), and very responsible . Recycling of PET is possible in the garage conditions, anyhow was water and electricity for the machine . Then the whole debate rested in the terminology of pet and pet if you understand different concepts, but you don't go into the details and just throw out the window .

You are on the Barnaul tire factory come to visit, that's where the mother of his utopia!

174bumer

first 7, 8 other price category

in the second 7 as 1-2 season no spikes

And after three seasons with the studs everything is fine (- 5 pieces on the wheel during aggressive and high speed driving — the little things!)

Vnuks

Strangely, I have 5 winters 7 Hakka and not ONE off of a thorn.

Exploitation is not a pensioner, regularly chase at gully and slip a lot

5 and 7, a single spike coming out. Season 6 mileage here and there about 50 60 tycm. Label wear eight not erased.

Pokrovchanin

Have you tried Haqq 8? The fifth season 8-ka is not erased! On each wheel there is from 5 to 8 spikes of 190!

I tried 7рку and 8рку rezâ bomber 7рку after 4reh seasons to finish tried, rushing on the route 140 on asphalt thorns bent like a porcupine, erased to 4верки. Sold. On 8рке all season ottdal on ice has shown itself to be great! Also was delighted with the Hakka blue in a downpour on the highway to 120. Right now, the summer Michelin primacy 3 stuff redkosny! Winter Nordman 4 is not Nokia! For next winter I'll try to find 7рку or 8рку in the B/U version. At my suggestion, the two neighbors 7рка one delighted second not)))

Have you tried Haqq 8? The fifth season 8-ka is not erased! On each wheel there is from 5 to 8 spikes of 190!

the third season of Hakka 5-all spikes in place. The best rubber 4 and 5,the rest is shit. Pumping money. Tried after 4 and 5 Haqq 7-shit, back on 5ku.

Cool, straight cool...it would be if the Russian Hakka black suv was not erased to slicks for 10 thousand km((

Otezdil three or four seasons on the Hakka 7 (Finke), very much, compared to Gislaved, this winter is also looking set. Looking for used, as 16's new are quite expensive, and then turned up a set of two pairs for half price from new. And one pair Finca, brought from Europe, the other maid in Rusland, that is, with this plant in Vsevolzhsk, and interestingly one tire of a pair of indicator eight, another six. It turns out on the driver's side and on the master and on the slave Finnish rubber wheel and the passenger "is our Russian"... And the spikes roughly equal, there, there... That's the spring and see the quality products manufactured at our factory?

Are you serious?! Nonche to find a Nokian tire made in Finland almost not real. Only some dimensions(mainly profile) there is not produced in Russia. So I have a bus of our bottling

I agree, and I'm sure all that's true just look there accidentally there is no inscription "Made in Finland"?!

And here's my photo of the tread khaki blue 2 SUV after one season and run 27t.km. Naaaaa geee! Even as much as 5mm in rest. That is, the tires will last 40-45T.km

So it looks like someone popahivaet

Can! Really tire of these fucking threw!And even pictures would be thrown off! We live close to Estonia and the Finns well, not so far that the rubber BU every seen and have something to compare!

And you for the word answer? Can you confirm anything that rolled summer tyres Nokian zero for 12T.km measured and confident riding?

Damn I already 50 I drive very confidently and methodically but in a g... as the NOKIAN I've ever seen! The brand began to mold us in a rush and as always it turns out that often we see in us! As one respected entrepreneur from Kaliningrad said, "you Know what I was fighting on your enterprise Is SAYDET, and SO"

Have You tried to go quietly and not make a fiery ride? I, for example, during the summer season and 25-28T.km. mileage not manage to roll the tires Nokian to zero. Tread 4-6mm. I say This from years of experience. Summer tyres are changed annually. Old take off on Craigslist. And still no summer tyres Nokian I'm not wiped out for the season(car and tyre models are different)

I absolutely agree with Abgemacht, I personally on the summer tires of this brand and traveled 12,000 miles and tires are at zero! They probably go on Nokia from Finland who goes by 40,000 km, and Even BU. Rubber Finke longer walks! I thank them for the quality!

It is not as interesting as it might seem at first glance, especially those who are daily in the "fields", I'm about 15 years spent directly in the production process, starting production of the bus "LiAZ" ending at the moment Renault, with intervals of tire plant Michelin and cable production and can confidently say that this is routine, daily, painstaking routine. Fight with the time and quality.

Currently working in a design component, includes component of interest, but it's all the same production. Worthy is our work report? Yes, God knows, the work of the rescuer, the worthy report, of the surgeon on duty, an emergency room doctor, they saved lives, my own work only to satisfy a fleeting need.

Why complicate things)

In Russia do car tires? — X*Evo!

After Nokian began to make in Russia, I changed my attitude to the manufacturer of winter tires... I used to Hackability prayed.

AndyWasHere

You may not care, but you should know that. Boring dull guys multiply itself around the sadness, sorrow and live a life of a loser. The losers are boring and not needed. They only Troll.

Apparently, it's the word "Playa", who somehow believes that now will never be a loser. It's funny, really. You where such terminology was picked up: "Playa", "loser", "to produce around the depression", etc? The meaning of these words can explain? At least to yourself.

Tyre Nokian Of Hakkapelitta-8. Bought in winter of 2016. Passed 3 winters. NO SPIKE IS NOT LOST! To roll properly the spikes! I about 500 km (at least) obazau spikes. No skid, no slip. And after that we could use rubber. Operation Moscow and the Moscow region. Ice the asphalt. The protector is NOT prone to aquaplaning. The only side hold a three. But save the electronic helpers in the car, and of course the HEAD!

Next tires will also be Nokian. Only now on the crossover (before the Sedan was). Sorry there are no discounts if you buy tires from one manufacturer... Bought in an Internet store. Outgoing address Tula. There's probably Resellers sit.

The wheels are completely satisfied!

Full size

Full size Full size

Full size Full size

Full size Full size

Full size Full size

Full size Full size

Full size Full size

Full size Full size

Full size Full size

Full size Full size

Full size Full size

Full size Full size

Full size Full size

Full size