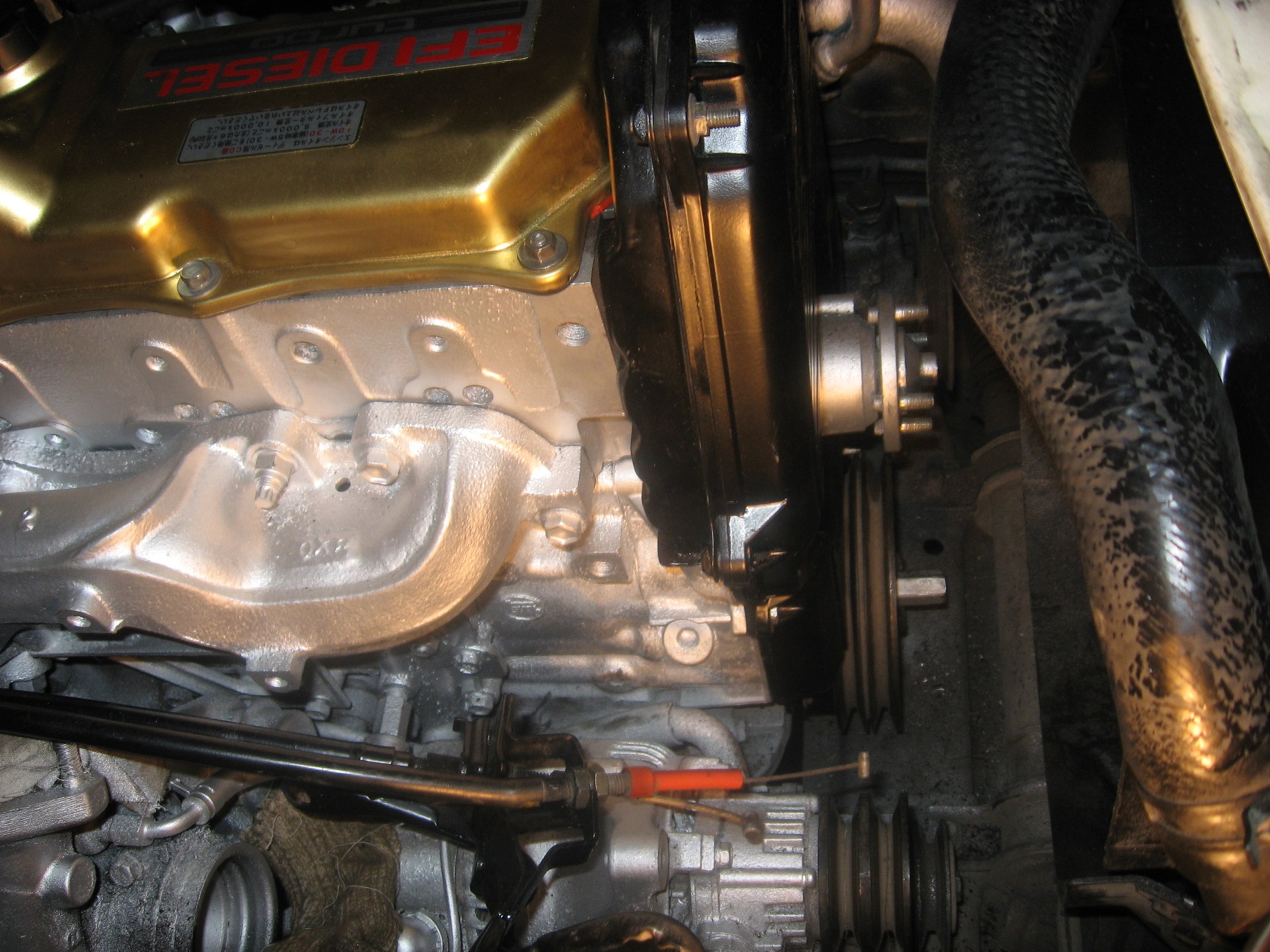

Fitting 5 (idea). - Toyota HiAce, 2.4 L, 1992

I can't rest the thought - Why wasn't the pulley tightened on the shaft. Believe me, I changed my mind a lot, BUT ?! From the beginning of the assembly, I did not leave the thought of how to do it, so that under no circumstances! OH! - could not unscrew. (Worse NO! - go and wait podlyany). This is where my thought came to. Maybe where it is applied (principle), I have not seen or heard. In short, this is what I navayl today. 1-pulley in place, well there is a second. 2-screw in the stopper but free. 3-4-like a stopper in a pulley. I remembered about the nuts in the hub. There the counter-washer fixes the nuts. I wondered what, what, and how-well, and here's the result. I know it looks rough (it’s not visible there). the ears in the pulley are fixed, and the plates, after tightening the screw, squeeze his dear one tightly to the figure and tighten with clamps or drip by welding - there are not many options. I will tighten with clamps.

Well done, this method of splitting is used in the rollers of all-terrain vehicles such as my GAZ-13, You can make a washer out of metal about 1.5-2 mm, and the edges of the bend are shorter, it will hold without a clamp and welding, but your version has the right to life, squeeze along edges and normovsky clamp

Hi, don't overdo it, you will tighten it up so much that you won't unscrew it later, but in general well done, it should be so, you do it for yourself.

You are right. 7 Clamps were used today (the most resistant remained). On the glue, the threaded screw tightened. Filled the screws in the clamps with glue. And also with super glue instant between them.