Installing a mechanical boost pressure sensor Apexi — Toyota Mark II, 2.5 liter, 1996

I bought the sensor and podium at an auction in Japan. It was originally a jamb — the backlight did not work! But well, my friend tinkered, cleaned the contacts and it all worked)

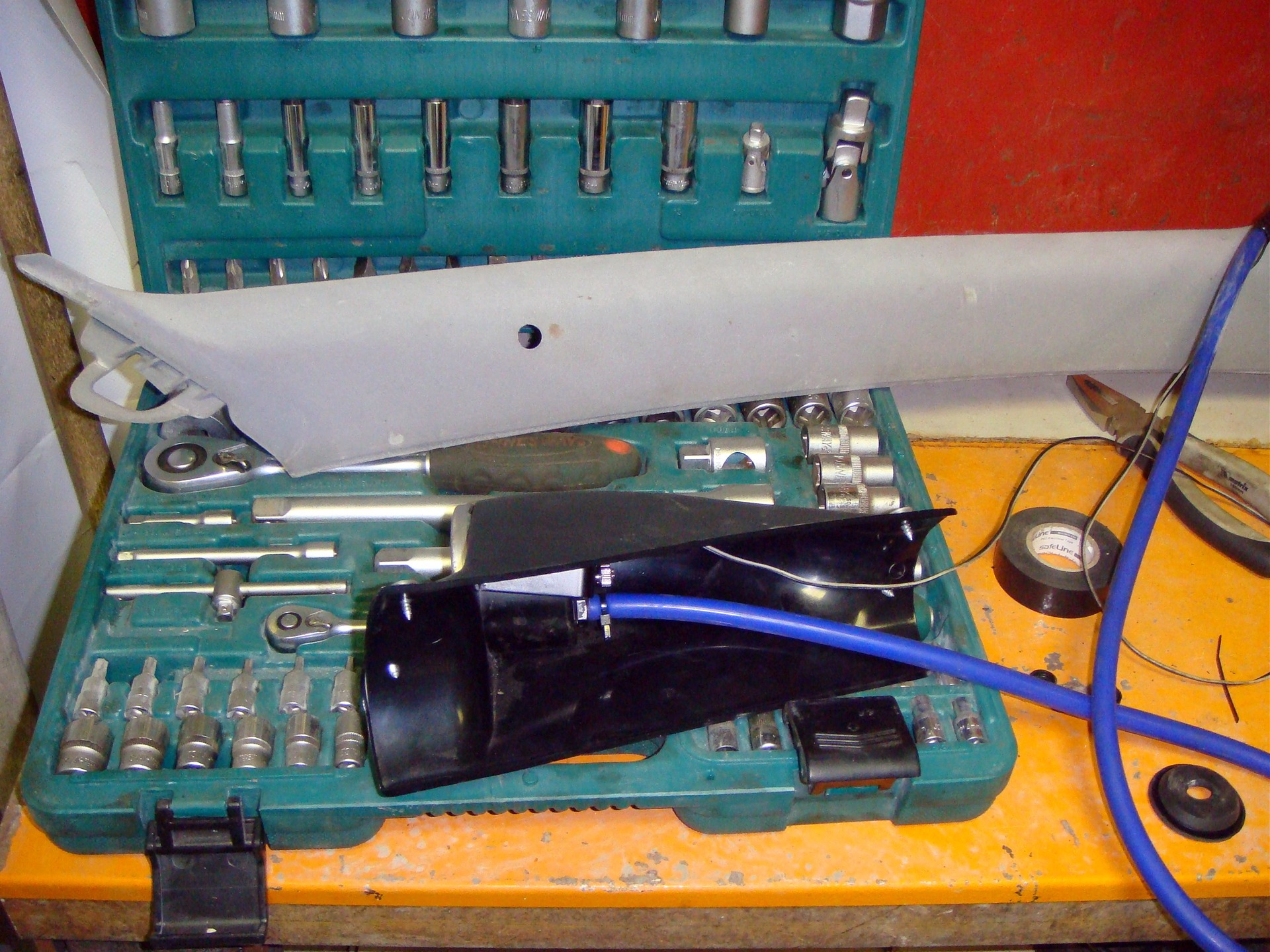

Let's start with what we need during installation: -

a silicone vacuum hose of about 2 meters (depending on where it will be located and on the location of the intake manifold)

- plastic

ties - electrical tape -

voltmeter

-drill

In my case, we put the sensor in a special Greddy case on the right windshield pillar. We will also need to get to the ignition switch in order to connect the sensor power to it and the backlight will light up with the turn of the key. To do this, we disassemble the panel at the driver's feet and remove the rack trim. This must be done very carefully otherwise the lining may crack. The plastic is very brittle and has dried out over time. Before removing the lining, you need to roughly outline how the podium will stand.

Next, we drill a hole in the rack overlay in order to pass the silicone hose and the power wire. We install the sensor in the housing, fix and connect the silicone. We fix the tube with a coupler so that it does not fly off and does not suck in air. Then we drag the tube and wires through the hole and fasten the podium with the sensor to the rack overlay.

We wind the backlight power wires with electrical tape to the silicone tube - it will be easier to push through the torpedo. We carry the entire structure in the car and begin to drag the hose inside. I have some wires going along the rack and going into the torpedo, so through this hole we pass our tube. Then we push our hand under the torpedo and stretch the hose inward. now the pad with the podium can be put in place and continue to connect. I have a technological hole plugged with a rubber band in the motor shield on the driver's side. I took it off, made a hole for the hose, passed it inside the engine compartment, and put the rubber band in place along with a piece of noise, then carefully laid the hose along the engine shield to the intake manifold, securing it in one place with a coupler. I have a free fitting on the manifold, on which there was a plug,

Now it remains to connect the wires to the sensor backlight so that it lights up simultaneously with turning the key in the ignition. I remove the chip from the lock and study it carefully. I need to find the wire that is energized when the key is turned. I found the inscription IGN on the chip, a yellow wire came up to it. I took a voltmeter, connected the red end to this wire, and connected the black one to ground to the body. The voltmeter showed 0, then turned the key in the ignition and the voltmeter showed 12v. Everything, the necessary wire is found. From this yellow wire that goes to the lock, carefully remove the braid about 0.5 cm wide and connect our positive wire, which goes to the sensor illumination. Everything is isolated, and we close the negative wire to ground by screwing it to any bolt on the steering column. Then check, when the ignition is off, the backlight does not light up, but when you turn it lights up - everything is OK!

Next, we assemble the torpedo under the driver's feet and that's it, the sensor is installed!))

When you start the car and it is idling, the sensor shows a vacuum, the arrow drops below zero. When you press the gas and the turbines create pressure, the arrow moves to the positive zone and shows the boost pressure, i.e. BOOST!

Good luck, Igor aka "Prince" Sukhov SilektrS!

Mileage: 97.000 kmI connected a pressure sensor to the hose that goes to blow off at idle, it shows a vacuum of -6, I press the gas, the arrow stays at zero, but at the same time, blow off releases a huge amount of air, so zero pressure can’t be, but if I I connect the pressure sensor through the fitting near the throttle valve, then the arrow jumps to 0.6 bar at the time of reset, what to do how to connect