-=*(Manufacture of a replica of the D-Speed ​​plastic hood)*=- — Toyota Corolla Levin, 1.6 liter, 1999

After seeing the beauty at Japanese auctions and talking with practitioners working with fiberglass and resins, as well as calculating the approximate budget, it was decided to independently manufacture a plastic hood.

The photo of the D-Speed ​​hood with air ducts and measurements of the nostrils of teammates who own this original were taken as the basis.

materials for the manufacture of the hood. available in open trade. like glass mat, fiberglass. and polyester resin ... (plus every little thing ... brushes, respirators, polyurethane foam, polystyrene, etc., etc.)

.the whole process took two weeks, due to the production only at the end of the working day in the middle of the week + weekends…

they fooled more with the profile of the air duct ... - architectural plasticine was used.

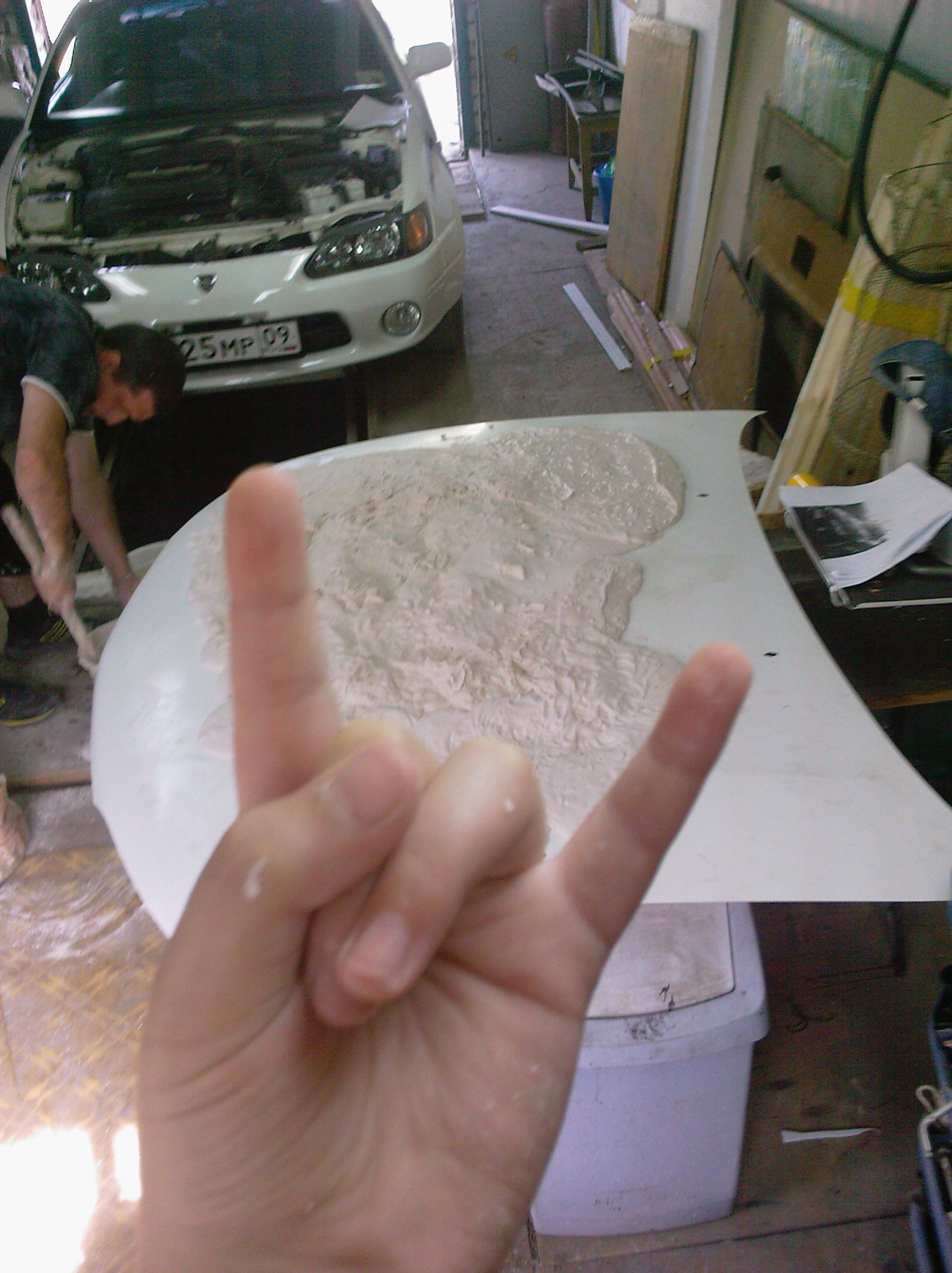

.with certain tricks, the next step was the production of a gypsum matrix and its subsequent reinforcement with foam and polystyrene ...

.after drying ... a day later they removed the matrix.

and prepared a continuation of the air intake on the back of the gypsum matrix ...

...then came fiber, glass mat and polyester, which is very "funny" for perception... =) ...respirators practically did not save...

…while the cowl face fiber was dry. started removing the matrix of the back of the hood. in order to keep all the stiffeners available on the original iron ...

.well, and connected both parts together ...

The long-awaited disposal of the gypsum frame ... - that's what happened.

… and the final splicing … and for one installation of fasteners and an ear under the hood lock.

... at the end it remains to cut off the tails. and try this miracle on the car ...

... The conclusion is simple ... as Kostya Kinchev sang. "…all in our hands." - in general, it's not difficult ... yes, there are subtleties that you learn along the way ... but in general, everything is real.

PS. The hood is waiting for putty and apparently pasting in a carbon film…

Issue price: 4,000 ₽ Mileage: 163,000 kmI think I saw these two in muzzles somewhere. And as for the cans, it’s right - I poured beer there and didn’t need to take it off. Yes, in the story I didn’t specify the most important point - about the amount of alcohol drunk

Well, yes, yes, tell me ... I’ll lay everything down as they drank everything, but they didn’t leave me) -)-)

in winter, this is clearly not where it will be done, but it will be seen there, thanks)))

Vital nothing is impossible! I’ll soon finish what I started - I’ll drop a photo ...

If necessary, I’ll sign the whole technology. ;)

... and what is there to think. =)

information on materials, preparation and the process itself on the Internet shaft ...

.with a friend purchased materials ... drilled into the box and go! )))

... slowly after work and on weekends ...

the price of materials up to 4 rubles - maximum!

... the rest is hands, head and a little bit of nerves. ))))

Yes, there would still be time to deal with this in-line ...))))

And so, in essence, nothing complicated ...

Great job! Judging by the joints on the car, it turned out very well. You can put it on stream =) Not a bad colym in theory)))

accurate measurements were not made ... I can measure ...

according to personal feelings, no more than 5 kg. ))))

PS ... added a photo to this effect - where both parts were fused ...

my friend. without straining, he holds it on one finger ...)))))

Yes, not really excellent. for work. This summer I myself fucked :) the first experience with resin and glass mat. Kaif something else to blind

Thank you Zhen ... about the final result, it will be seen how I fit it or paint it =)

... the question is stuck EXCLUSIVELY in my free time ... but in general it can be done. =)

Super! I would like to find such people, I would immediately do it for myself ... Do guys not work for export? :)

opanki, even attentiveness apparently let me down when reading! Well done guys, I shake hands for akununuyu work! :)

Absolutely no problems ... knock in a personal or asya ... I'll tell you everything ... I will easily share my experience ... =)

oh, I would also make a plastic hood, native pipets what a heavy kg 20 probably

Has he gotten much lighter? How much is the weight of the original and homemade?

From gibs, because the only copy was needed ... :)

They sculpted from fiberglass, glass mat only for reinforcement in the middle layers ...

Only glass mat is not enough ... in practice, the design is too rigid ...

We didn't use epoxy, we used polyester resin!

And why did they make a matrix of gypsum?

Why not ordinary glass mat? As I see it, you blinded it from epoxy with fiberglass?))

The hood turned out to be smooth and everything is wonderful in terms of rigidity / flexibility ... :)

but the fact that a bunch of small notches from the air on the gibs is yes ...

... and that is not critical - it is leveled with the thinnest layer of special putty ...

... and then the film. :)

and the hood was not lubricated or covered with anything, so that the gypsum matrix would not spoil it? Or does plaster not stick?

great job, but there is a better offer, since so much work has been done, why spoil the beauty with a carbon fiber film, you can tighten it with carbon fiber (carbon fiber) it’s better and no more difficult than the hood itself

, well done, so I decided to do my own and your experience helped me a lot

gelcoat is it if it is made of fiberglass, or do you think it is possible to remove gypsum with its use?

Silicone is sold in tubes. ;)

In general, it is already easier and more reliable to make a matrix using gelcoat. ;)

thanks! what about silicone? can you tell me more? I'm also going to remove the matrix and I'm afraid that the plaster will remain on the product)))

Super job! but I was afraid to make a remark from the spoiler ...))) now I'm not afraid)))

Hey!

Bookmarks on a metal base ...

That is, metal plates as bases to which are welded, a loop and hinges ... =)