Crankcase protection - Toyota Hilux Surf, 2.4 liter, 1991

The standard protection (slightly modernized by us) was left in the swamp back in the summer (They twisted / bent when they were pulled out by the tractor: ()

Now, thanks to our navigator Andrey (Flanker), we bought a new protection. But I definitely don’t recommend anyone to take the same one!

We initially took it as a basis for a home-made one, but we were very disappointed in this piece of iron :(

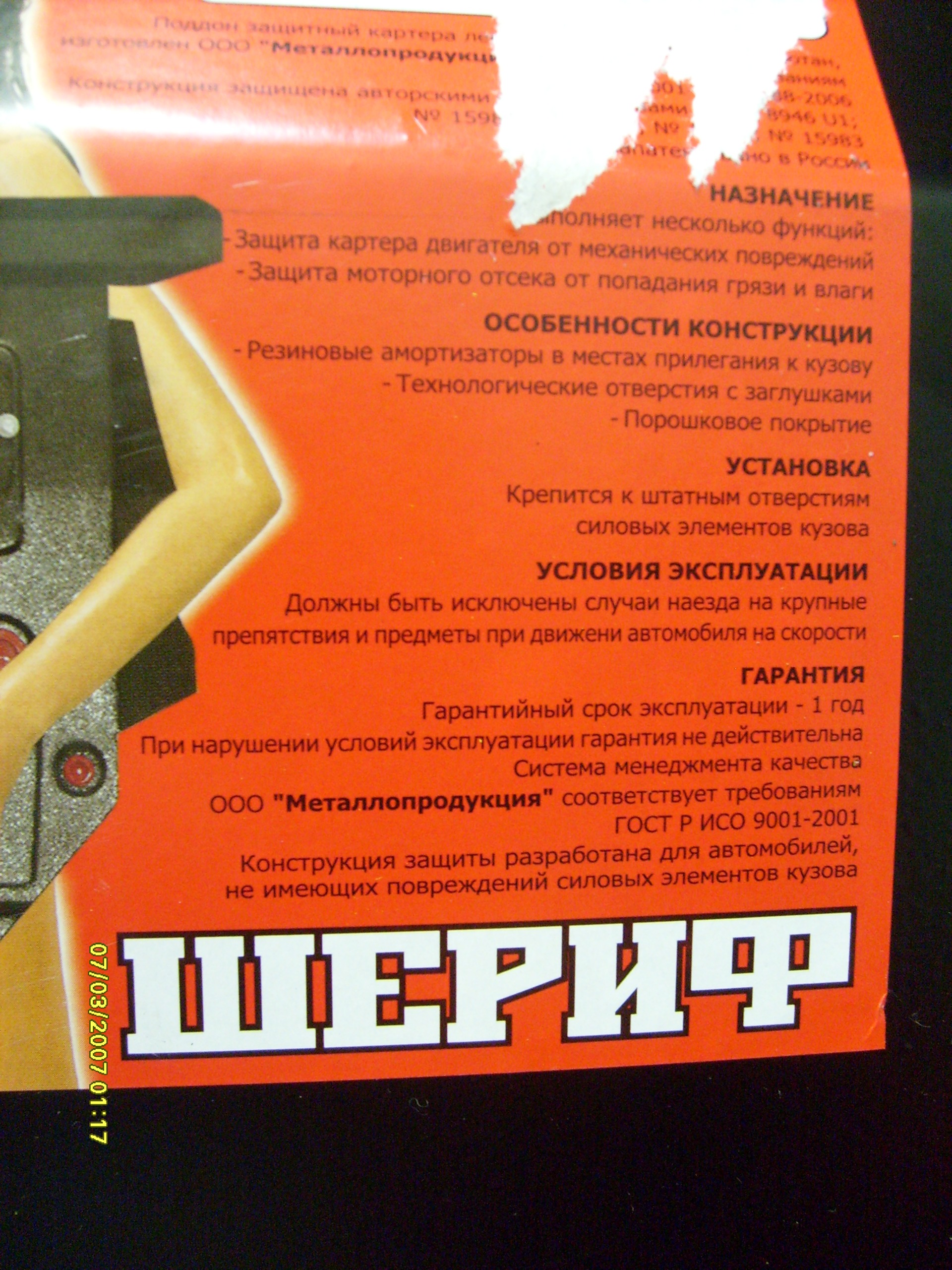

SHERIFF protection for our model

features: no rubber shock absorbers, technological holes with plugs, the coating is not powder coated, but probably painted with shipping paint ...

During installation, I had to re-drill 6 holes out of 6 ...

.

Well, since the rear bolt on the old protection broke, and the holes on the new one did not match the standard mounting holes anyway, it was decided not to drill the chip, but to weld the fastening nuts in neighboring holes. Our welder is resting in the village, so we went to the garage at night to good man Andrey Feropont and everything was welded there.

The next day they turned off the excess

There the edge rested and did not allow to fasten the protection.

and finally put up a defense.

We will go with her for orientation, and then we will digest, strengthening and removing the excess.

ps

a year ago, a sheriff and a friend put protection on his 4runner. There was the same story with overdrilling, bending, cutting, etc. Then they decided that this was the runner. Now we are sure that the protection is crooked :(

is great. when you open the cork - a jet of half a meter sucks. we won’t fall and remove the protection every 8 thousand km ...

chevytoy

Only when changing the oil you need two people ...-)

And to do opposite the bolt?

:))) well, the minus of heavy protection was discovered. Or maybe a plus - together it’s more fun :)

chevytoy

wouldn't change! my protection weighs 98 kg… who can afford to install ship steel protection at the factory?

many security officials do not hang up or choose the lightest ones so as not to weigh them down ...

Although, probably, 100 kg is invisible for such a machine :)

wouldn't change! my protection weighs 98 kg… who can afford to install ship steel protection at the factory?

It has already been checked ...

I’m all so weak and for SUVs I call fittings ...

If they went to our raid once, I think all this fittings have radically changed.

vnedorog

Have you figured out the hub bearings?

And the best protection, as self-made, I have not yet met. Do not waste money in vain. Do it yourself

The rest is all for puzoterki

You say the truth !

Tomorrow we have a collection for the raid. On Saturday, Sunday we will jeep. Only on Monday

We have two Hi Luxes in the club, I'll ask about the problem ... We can find the reason

we didn’t have time to do it ourselves. we don’t have a garage in Moscow, so there’s no way to do a lot of things. I want to :(

We didn’t figure it out with the hubs :(((

Have you figured out the hub bearings?

And the best protection, as self-made, I have not yet met. Do not waste money in vain. Do it yourself

The rest is all for puzoterki

well, yes, we unscrew it with a grinder, we fix it with welding :)))

if it happens, we’ll say hello :)

Andryukha-Ferrych head and hands! Say hello to him on occasion from me!

Well, grinder-welding as usual when using an SUV)

I took it two years ago

. I have a bent from a single sheet.

Looks like pop music began to stick (

maybe as a simple protection sheriff and normal, but something was too clever there with the mounting holes and with the dimensions of the protection itself. This is no longer normal.

and where and how we ride, such a piece of iron is unlikely to protect normally, because the side blades are held on the main sheet thanks to 5 welding points, this is not serious: (((

You need to put up some protection yourself! On the shores of the Arctic Arctic 50 million times I remembered it and cursed myself that I didn’t put it (((

I also have a sheriff on the field, but there were no such jambs, everything falls into place, of course the holes are crooked, but the 2 parts that cover the anthers (as I understand it, they are for this) are separately screwed to the field. We put a log under it when the CV joint was changed, it seems to be holding. And I lifted it with a jack — right under the crankcase, it also seems to be whole for now =). We bought it 4 or 5 years ago though. In Bucharest, I crawled the entire track on it =)

zOrg47

Hmm give 2k and suffer so much with the installation. Now I will definitely go to our guys, let them do it themselves. Thanks for the info. He himself looked closely at the protection of the new one, the sturuyu was a bit torn and crushed by a log, while it was leveled, but this was not for long.

Let them weld squares with a hole around the fastening bolts - so that the bolt head turns out to be recessed into this square. Otherwise, from hitting the stones, the heads can kill until it is completely impossible to unscrew

Yes, if it is possible to do it right, then it is better to do it!

we bought protection from extreme necessity!

Hmm give 2k and suffer so much with the installation. Now I will definitely go to our guys, let them do it themselves. Thanks for the info. He himself looked closely at the protection of the new one, the sturuyu was a bit torn and crushed by a log, while it was leveled, but this was not for long.