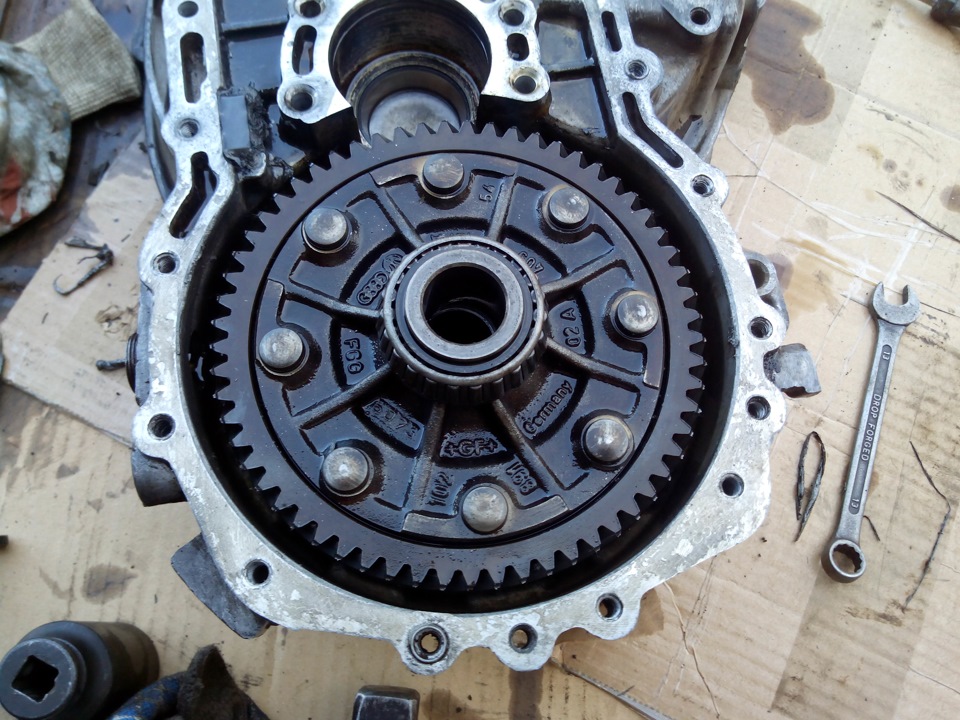

Replacement differential bearing, for example 02A CCM transmission

All welcome!

On "old" boxes given run and load most bearings fail.

it is the howling of the gears. noisy work.bad sticking gears, etc...

For example with the differential it so happens that when starting off felt a thud.

of course this is assuming the lack of backlash in CV joints.

So the bearings wear out and the diff just hanging.

.

We need to change the bearings and be sure to put them using the reg.washer.

.

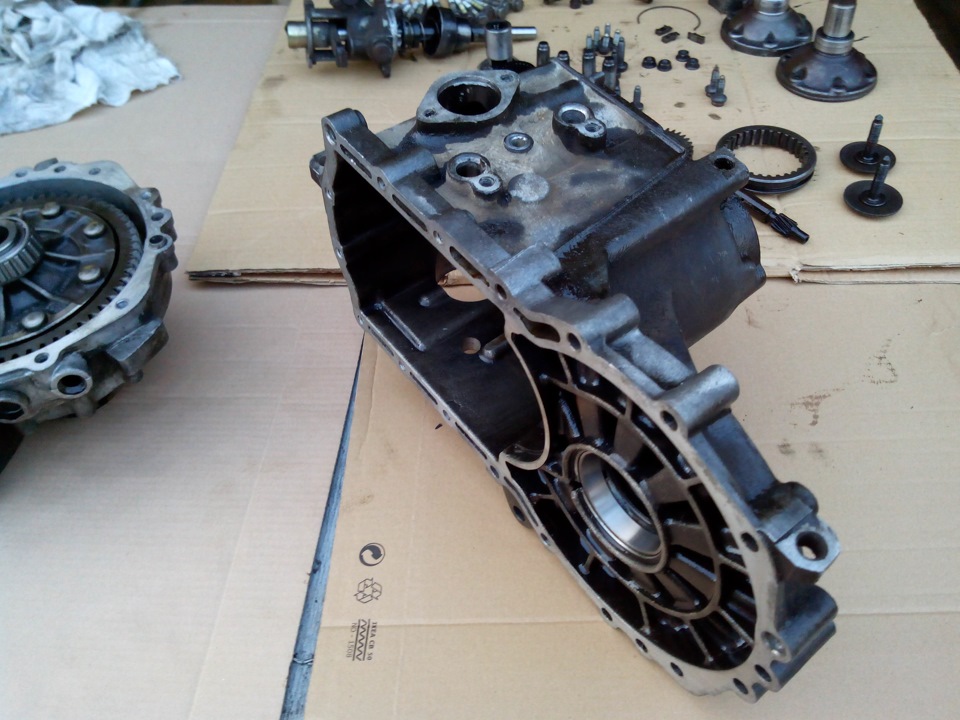

Before analysis of the CPR it needs to be cleaned up to "preoperational" status

.

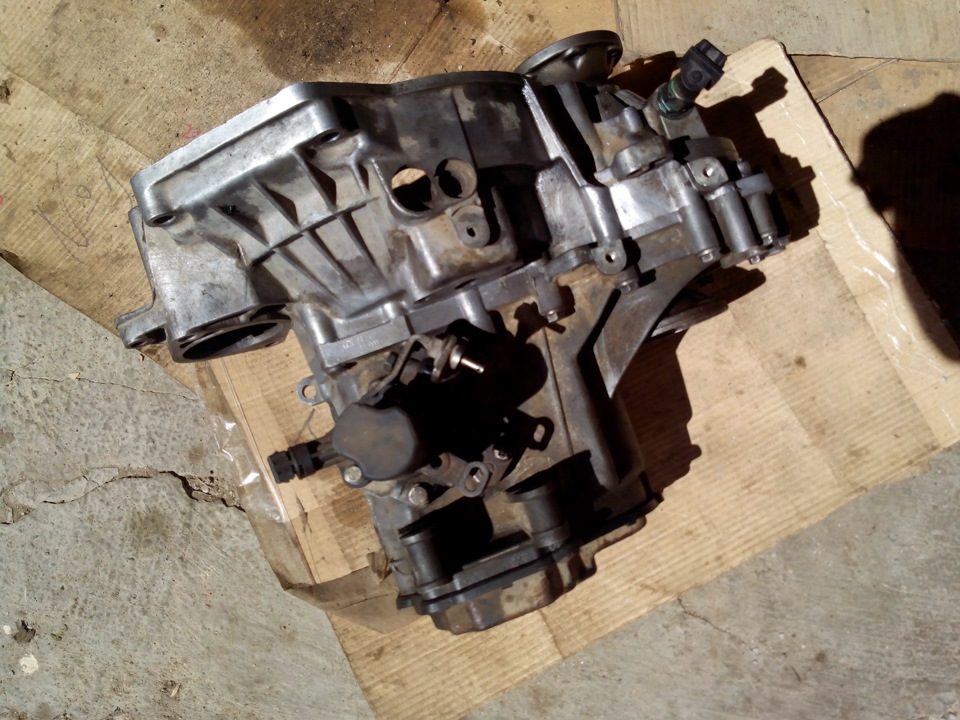

Remove the fifth gear cover

remove the 5 bolts M8 head on 11mm.

.

then removing the bolts gear, fifth gear puller remove gears.

.

Next, remove the housing and take out the diff.

.

Grinder cut the old bearings

New bearings installed only through the press

Method, where the main tool is a hammer will not work

Well, we put it back together.

thank you for your attention!

we have a little differently, but after replacing the bearings on the new adjustment of the preload is not required . the development was only in the bearings ( took exactly the same as standing )

I do so:

new bearings pressed on the diff.

there are separate new bearing races which are slightly reduced in diameter (literally 3-7соток to clip easily in and out of the transmission housing.

The seals of the differential needs to be removed.

gather and twist the two housing parts .they only diff.

placing clips small washers of a certain thickness to achieve the differential was biased.but to rotate.

made by eye.have experience.

After all disassembled. installed under the cage shims of the necessary thickness.

clips are pressed.all re-assembled.

checks are not trapped if the diff and not loose it.

if everything is OK, then collect the checkpoint.

if not, vypressovyvaetsya the cage and all over again.

I do so:

new bearings pressed on the diff.

there are separate new bearing races which are slightly reduced in diameter (literally 3-7соток to clip easily in and out of the transmission housing.

The seals of the differential needs to be removed.

gather and twist the two housing parts .they only diff.

placing clips small washers of a certain thickness to achieve the differential was biased.but to rotate.

made by eye.have experience.

After all disassembled. installed under the cage shims of the necessary thickness.

clips are pressed.all re-assembled.

checks are not trapped if the diff and not loose it.

if everything is OK, then collect the checkpoint.

if not, vypressovyvaetsya the cage and all over again.

Good! Where to look for what the bearings are installed in the box? Vw t5 2006

If you bring the box will be able to change?

Welcome:) Question: what is the tightening torque of the bolts connecting the transaxle case (between which gasket sealer is applied)?

I have a question, answer if not difficult)

I replaced a broken finger satellites transmission AFE for the same. So here is a new box on the neutral I heard the sound inside, almost like something was loose) and in 1st gear when riding the same sound, more like a dead CV Joint. On the other programs all clearly.

There fell off or falls off and how she so praestat?

I thought about it. But I have no transmission for parts) I'll Try again with udhay and heat, then I will think. Thank you!

there was a time when nivkakuyu was not clutch this.

blunt pounded it across the grinder and took the clutch with another cat which was for parts

Yes, I understand that the clutch, conventionally, they say there is all this design in the collection. By the way, is it possible without removing the clutch to disassemble synch? To remove this ring, which enables the transmission? To try a puller to get the clutch itself? Normal puller is what? I kind of like normal, but the thickness of the jaws does not allow them to have a deep under gear, cling to the edges of the teeth. Therefore chipped. Coupling to heat to what temperature? A hair dryer will be enough or the burner? Hardening will not let go?

on the input shaft is pressed on there clutch transmission, not gear

the gear is there on the needle bearing is spinning

tip pour wdsci heated slightly and pull normal symptom

I'm trying to parse 02A, but the gear from the input shaft does not want to get off. Remover one tooth chipped. Trying to remove method without stripper:  — no, not even strahovatsya. What to do — mind I will not put. Warming burner is terrible, a hair dryer construction, and be a good judge?

— no, not even strahovatsya. What to do — mind I will not put. Warming burner is terrible, a hair dryer construction, and be a good judge?

Good day! Please tell me x trail t30 as if on the two gear box dependent. Trying to remove the top switching mechanism, but it is slightly raised and everything. What could it be?