Allowance for the replacement of silent blocks the upper arm

Want to offer a note of the method of replacement of silent blocks the upper levers on rulesafe (will be useful for other cars with a similar design of the upper arm). To replace you will need a good vise, some rings from the bearings of large diameter, two thick washers and the key 21. All operations are performed on previously de-lever.

1. The removing

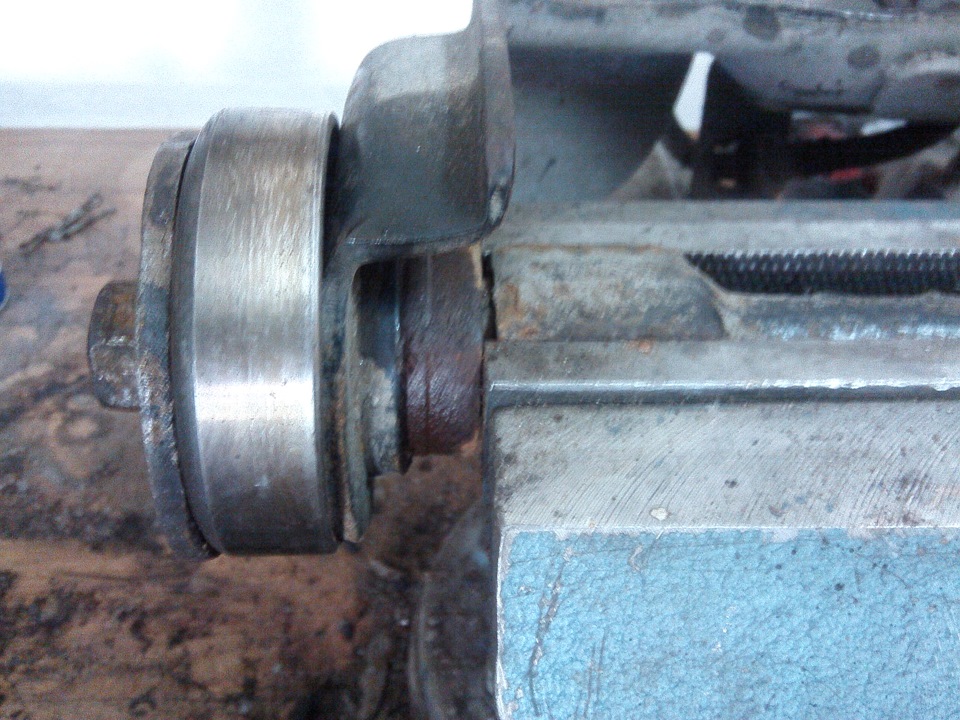

Since the axis of the upper arm is between silent blocks, use a press to disassemble quite uncomfortable. You can do without a press: hold the axle in a vise so that the outer basket silent ran into a vise.

Then take the bearing (or scrap pipe) of the diameter to ferrule rubber freely moved in and a thick large diameter washer. The whole "package" is compressed native nut. ring or scrap pipe

ring or scrap pipe washer and nut native

washer and nut native

Begin to tighten the nut and press out bonded rubber Bush from the arm. If silent is not, it is necessary to tighten the nut and knock the puck — silent needs to move. Repeat the operation "tightening-tapping" to complete a wheel. To facilitate the work with highly rusted silent, its surface clean of rust and pre-pour WD or something similar, you can also warm the burner. tightening and squeezing

tightening and squeezing partially pressed rubber block

partially pressed rubber block

The second rubber block is removed similarly.

2. Press

Before pressing, you need to clean the seats of the lever and the axis of rust. I recommend also to use the "Movil" as a lubricant when pressing — they covered the surface of the new silent, the inside of the lever and the surface axis.

Pressing plate, fasten the lever in a Vice using suitable spacers so that the outer basket silent passed between the jaws and the lever rested on the side of the grip. The pressing is performed by tightening the nuts through the big washer, put on top of silent, but without the rings. Press-fitted to the stop collar silent in the arm first with one then with the other hand.

Because when pressing the inner race silent is slightly pressed, the second press silent to stop in the described manner will not work — the inner race rests on the axle... to avoid this, you need to delay the axis as when removing curb and a second silent. on the left axis pulls the ring already pressed on silent, to the right is press-fitted silent

on the left axis pulls the ring already pressed on silent, to the right is press-fitted silent

I hope my method to someone will be useful)))

All the best!

UPD. IMPORTANT!

1. When removing the lever needs to pay attention to which side the axle silent blocks were converted to mount on the frame, because the thickness axis from different sides are different! Improper installation will lead to the inability to adjust the camber!

2. If You have silent blocks already changed, we strongly recommend that before installing a new one to check the alignment of the "ears" of the lever. Careless replacement of the "ears" are very easily bent and a new silenty will work with the imbalance, which will lead to the rapid release of node failure!

The test is very simple — take a smooth pipe with a diameter slightly smaller than the hole in the lever, threaded through the lever, pressed against the walls of the holes in different planes and see how snugly the walls of the holes to the tube. Ideally, gaps between the pipe and the lever should not be. If there is — the rules of the lever.

You can check and without the tube after pressing one silent (which side of the lever — no matter) it is necessary to insert the axle and check whether it is exactly in the center of the holes for a second silent. If axis not in the center — be sure to rule the lever!

3. Indicates the right of repairs — axis freely (or with little effort) rotates in sleeves Salento, while the axial displacement of the axes between the bushing missing or minor (1-2mm). If these conditions are not met — silent blocks fail prematurely.

4. After pressing the new silent-blocks mounting nut from tightening is not necessary, final tightening Salento on the axis produced by the weight of the car. For ease of tightening instead of a wheel I recommend to expose the rack, the height corresponding to the actual wheel.

for reliability — after 100 thousand silent blocks better to change, even if outwardly they have no problems

if there is no Vice necessary) because I did it for an hour or two in one hand, and the hundred blew the all-day brain bscva, and salamini would be the price tag that they almost clutches in automatic transmissions have changed, and sagely vparivali would like all complex and important)))

About the axis of the agree, therefore and wrote that it is necessary to pull gently and if it doesn't — tapping. A score silenty (as well as other components and parts) I'm not a fan of hammer I try to use a ka less often)))

but, I'll tell you the axis of the lever is not so steep on the strength of once having tightened the nut, I broke off the axle and pulled not much to say to, so be warned)

I have a similar method, the current is completely nischebrodsky, no grip, and I pulled the tubes, put the spacer in the lever as it is bent, and preswell second silent hammer worn hammer on the pipe with the washer, the main thing to do in this method is a good spacer.

with a hammer and chisel long not doing anything))) the inhumane way however... and as axis you can not worry — it's the axis of the lever. on it a quarter of the weight of the car hanging...

on the classic Zhiguli lower control arms are very similar, and the axis.

these bushings can be removed with a hammer with the chisel. to the axis of the lever it will be less painful

break1

I mean, without a press not to manage, clean will not work — not to crawl.

and press just the "ears" of the lever and crushed... then have to align that alignment to restore!

why can't you? everything is great clean normal file and a large strip of sandpaper!

God... if zachys — clean and warm! why all strive to use the thread as tasaciones press?((( no fanaticism necessary, carefully! excessive diligence can and x... break)))

Squeeze on the native thread is not much more humane than a hammer and chisel — if silent well zachys — thread pull — and all — just throw then...

now all services to smoke, except official.

crisis... all in the garage moved repaired, study the math part)))

not everyone can do even such a simple operation))) services will not be empty...

Today, only bought for replacement.

Find time and go!

Thanks for the tips. In bookmarks!

So on a classical Zhiguli same leverage. So everything changed, not only in Vice, and right in the archway to the car.

stuck or not — it should be known before disassembly, just to try to pull the axle silent block... and of course, if stuck — need a way much more radical than that proposed)))

so it is possible to bend the lever if it is stuck bushing on the axle . there are for this mill 5 min to replace both.and generally it is better than the chisel and hammer.+1

puller bottom saleblow from the VAZ 2101, and 250 rubles for it will not fail(just fresh out of rawhide, and for a long time is not enough), and replacement will take place, judging by the picture, even this thread, and lever design